Liquid, chlorine-free, early-strength anti-freezing polycarboxylate composite water reducing agent and preparation method thereof

A technology of composite water reducer and polycarboxylate, which is applied in the field of antifreeze concrete admixture, early strength antifreeze polycarboxylate composite water reducer and its preparation, and can solve the problem of high alkali content of antifreeze and harm to human health , containing urea and other problems, to achieve long-term storage uniform stability, good antifreeze performance, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

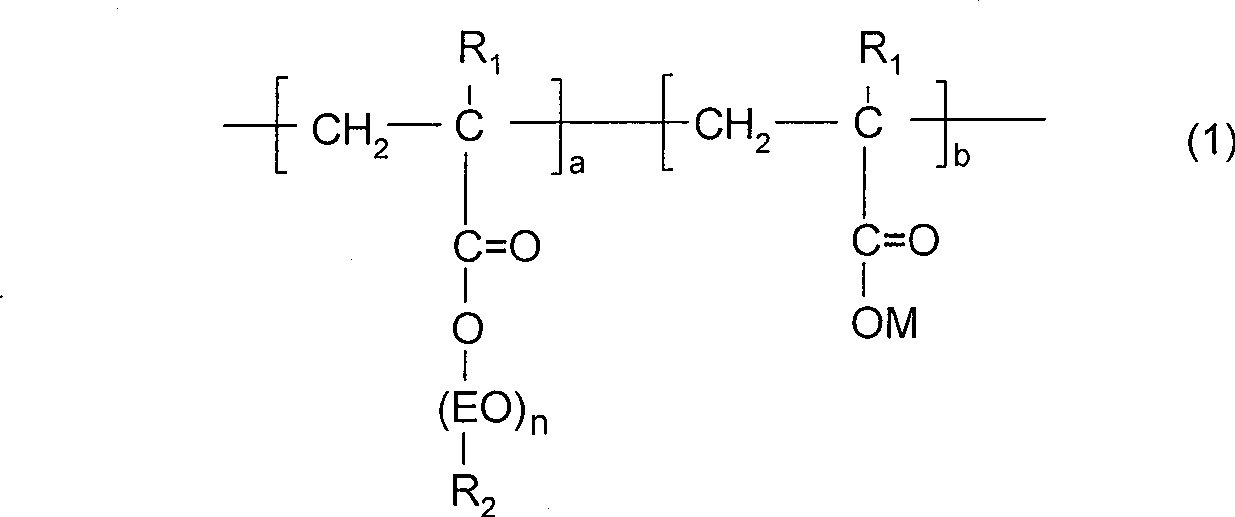

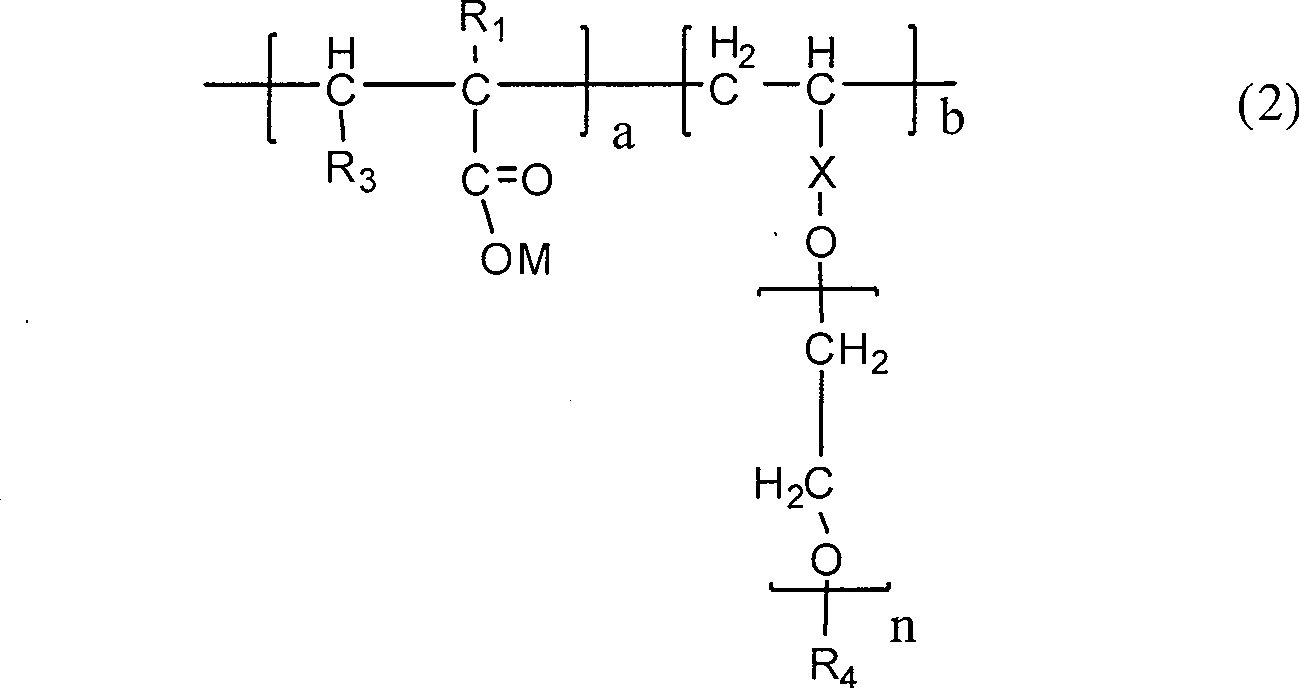

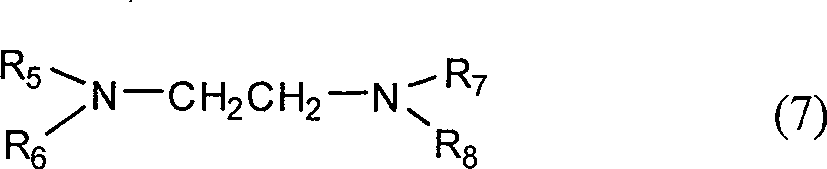

Method used

Image

Examples

Embodiment 1

[0054] Add water 367kg in 1000L reactor, drop into polycarboxylate superplasticizer (PC (a)) 200kg (40% effective weight concentration) successively behind, ethylene glycol 60kg, tetrahydroxypropyl ethylenediamine 20kg, thiocyanate Magnesium acid 100kg, calcium formate 50kg and rosin resin air-entraining agent 3kg, stir until it dissolves into a uniform solution (about 20min), and the weight concentration is 39.2%.

Embodiment 2-4

[0056] The preparation process is the same as in Example 1, except that the types and proportions of raw materials used are different, as listed in Table 2.

[0057] Table 2

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com