Special lubricating oil for dobby

A technology of lubricating oil and dobbies, applied in lubricating compositions, petroleum industry, etc., can solve the problems of no more research on the environmental protection performance of dobby lubricating oils, frequent failures of electronic dobbies, etc., and achieve excellent extreme pressure Low performance, anti-emulsification performance, extended oil change interval effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

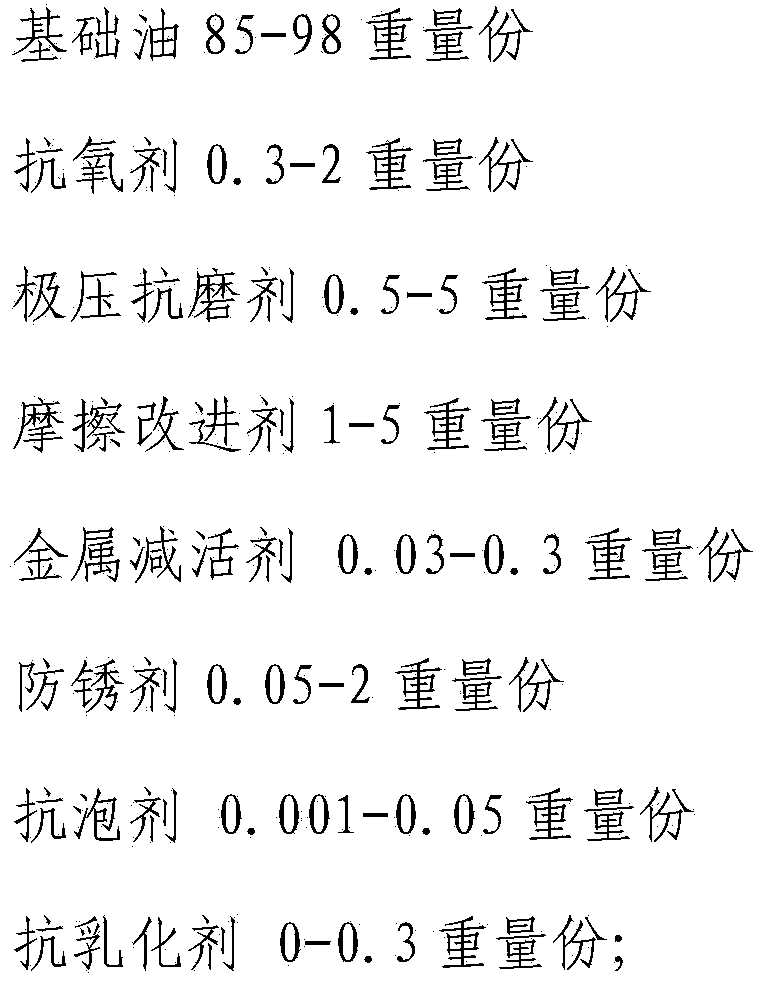

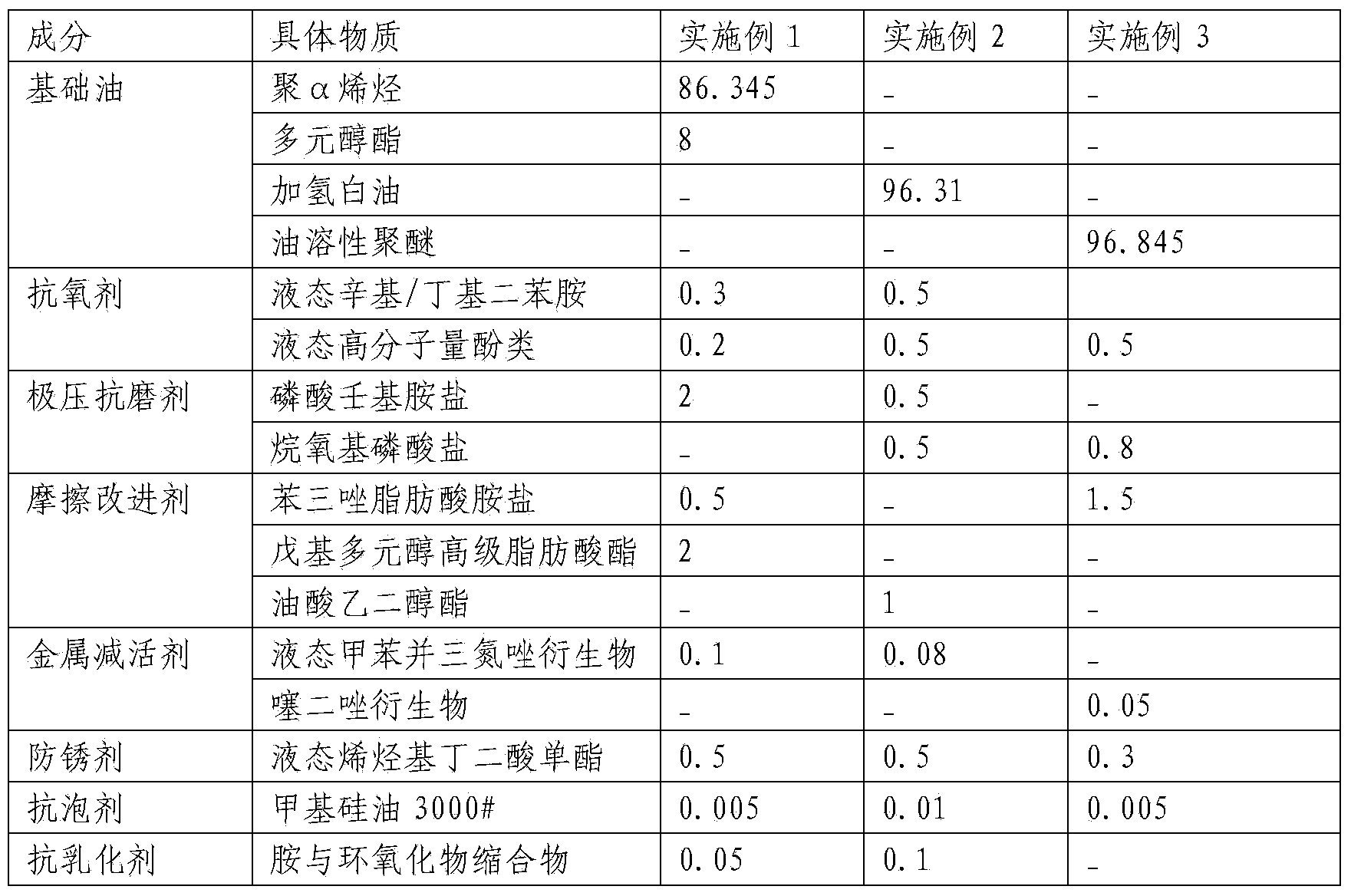

[0022] The following table is the parts by weight of each component of three preferred embodiments of the present invention:

[0023]

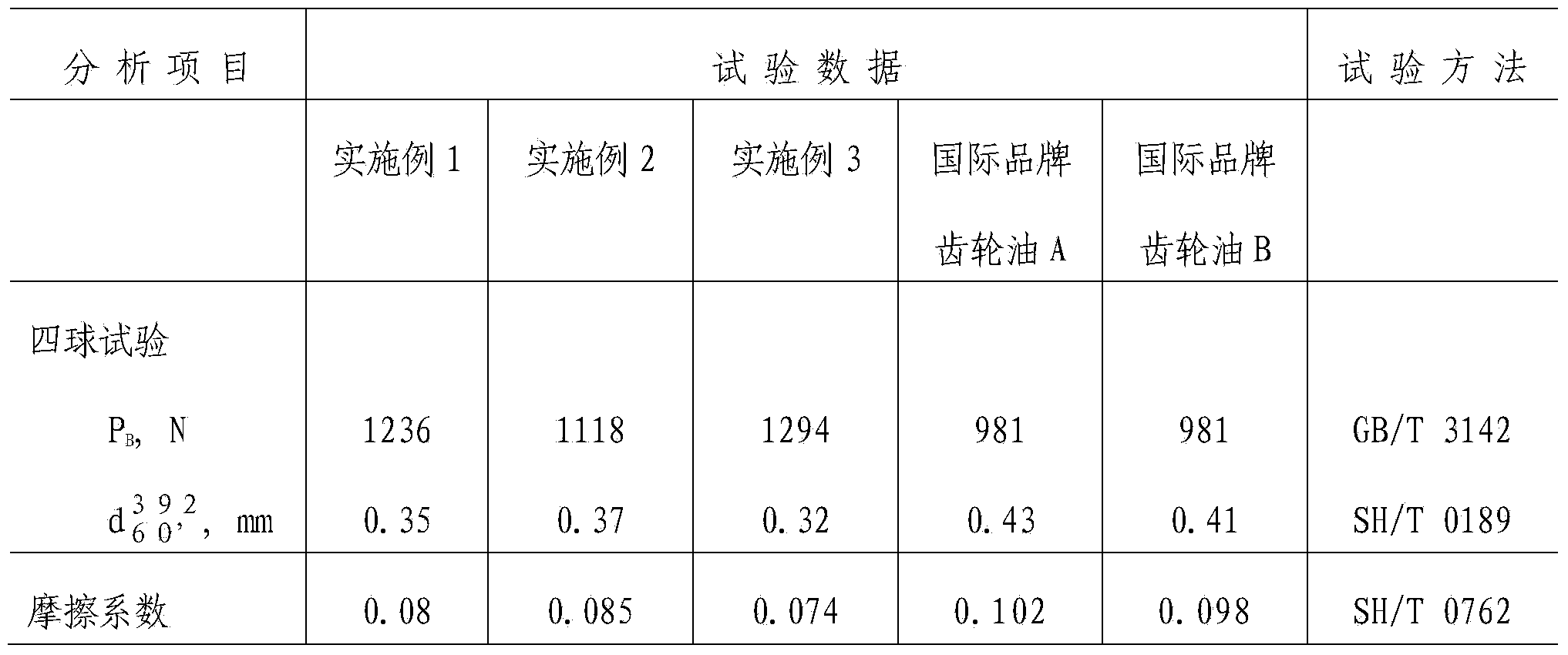

[0024] Compared with the existing gear oil, the present invention has the main advantage of anti-wear performance. In this regard, we compared the anti-wear properties of the products of the three embodiments with two international brands of gear oils. The results of the comparison are as follows:

[0025]

[0026] It can be seen that the anti-wear performance of the special lubricating oil for dobby in the embodiment of the present invention is obviously better than that of foreign brand gear oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com