Dispersive chlorine-free low-temperature early-strength agent used for oil well cement and cement mortar including same

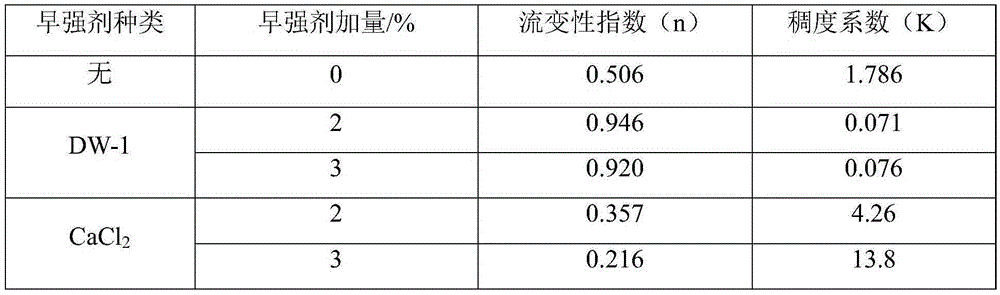

A technology of low-temperature early-strength agent and oil well cement, which is applied in the field of oil and gas well cementing. It can solve the problems of decreased sulfate resistance, increased permeability of cement stone, and increased yield value of cement slurry, etc., and achieves good early-strength effect. Effect of increasing density and improving rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

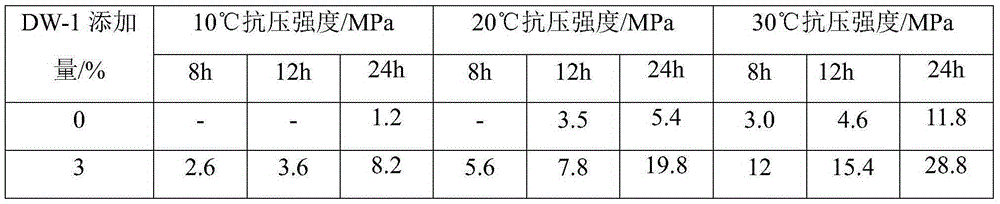

Embodiment 1

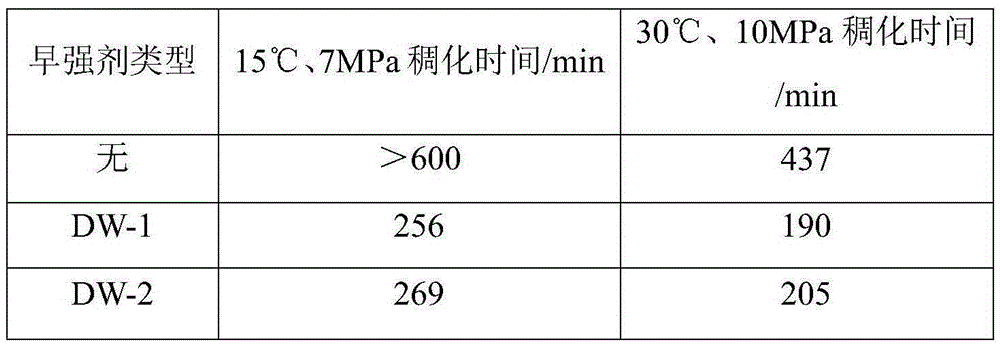

[0029] According to the mass ratio of sodium sulfate: SP30 nano-silica: sodium aluminate: triethanolamine: water reducing agent = 2: 0.8: 0.2: 0.05: 0.35, add the above-mentioned materials weighed into the mixer and mix them evenly to obtain Low-temperature early strength agent, denoted as DW-1, in which the water reducer is composed of polycarboxylate acrylic water reducer and aliphatic aldehyde and ketone water reducer in a mass ratio of 1:1, polycarboxylate acrylic water reducer Both the water agent and the aliphatic aldehyde and ketone water reducer were purchased from Qingdao Hongxia Polymer Material Co., Ltd.

Embodiment 2

[0031] According to the mass ratio of sodium sulfate: nano silicon dioxide: sodium aluminate: triethanolamine: water reducer = 1.5:1:0.3:0.04:0.4, add the above-mentioned materials weighed into the mixer and mix them evenly to obtain low temperature Early strength agent, denoted as DW-2, in which the water reducer is composed of polycarboxylate acrylic water reducer and aliphatic aldehyde and ketone water reducer in a mass ratio of 1:1, polycarboxylate acrylic water reducer The water reducer and aliphatic aldehyde and ketone water reducer were purchased from Qingdao Hongxia Polymer Material Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com