Liquid alkali and chlorine free setting accelerator and preparation method thereof

A technology of quick-setting agent and liquid, which is applied in the field of liquid alkali-free and chlorine-free accelerator and its preparation, can solve the problems of short final setting time and short initial setting time, achieve improved stability, improved performance, promote dispersion and Solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

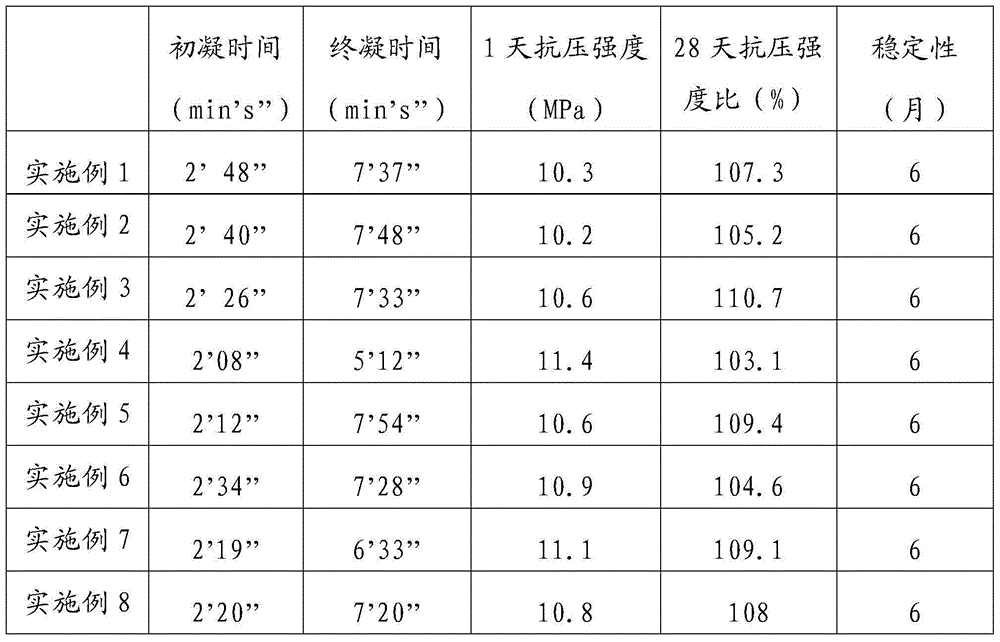

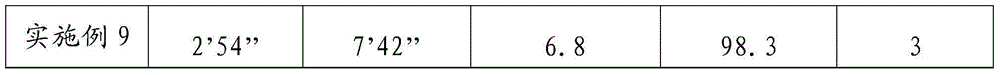

Examples

Embodiment 1

[0031] The liquid alkali-free and chlorine-free quick-setting agent raw material formula described in this implementation includes the components of the following parts by weight:

[0032] Aluminum sulfate 60kg, magnesium fluorosilicate 2kg, magnesium oxide 0.5kg, calcium formate 5kg, ferrous sulfate 5kg, monoethanolamine 20kg, fluorosilicate 1kg, polyether 2kg and water 50kg.

[0033] Prepare liquid alkali-free and chlorine-free quick-setting agent according to above-mentioned raw material formula, comprise the steps:

[0034](1) Weigh coagulation accelerator, coagulation accelerator early strength agent, early strength agent, complexation accelerator, stabilizer, inorganic acid, defoamer and water according to the above formula, mix and stir under heating conditions at a temperature of 35°C Evenly, the stirring speed is 35r / min, and then cooled to room temperature to obtain the quick-setting agent mother liquor for subsequent use;

[0035] (2) Add the quick-setting agent mo...

Embodiment 2

[0037] The liquid alkali-free and chlorine-free quick-setting agent raw material formula described in this implementation includes the components of the following parts by weight:

[0038] Aluminum sulfate 130kg, magnesium sulfate 0.5kg, ammonium fluorosilicate 2kg, calcium nitrate 0.5kg, ferrous sulfate 15kg, diethanolamine 8kg, phosphoric acid 5kg, higher alcohol fatty acid ester 0.25kg and water 75kg.

[0039] Prepare liquid alkali-free and chlorine-free quick-setting agent according to above-mentioned raw material formula, comprise the steps:

[0040] (1) Weigh coagulation accelerator, coagulation accelerator early strength agent, early strength agent, complexation accelerator, stabilizer, inorganic acid, defoamer and water according to the above formula, mix and stir evenly under the heating condition of 65°C, The stirring speed is 90r / min, and then cooled to room temperature to obtain the quick-setting agent mother liquor for subsequent use;

[0041] (2) Add the quick-s...

Embodiment 3

[0043] The liquid alkali-free and chlorine-free quick-setting agent raw material formula described in this implementation includes the components of the following parts by weight:

[0044] Aluminum sulfate 81.5kg, mixture of magnesium fluorosilicate and magnesium sulfate 1.5kg, ammonium fluorosilicate 1kg, calcium nitrate 4kg, ferrous sulfate 7kg, triethanolamine 15kg, hydrofluoric acid 1.5kg, polydimethylsiloxane 1.5 kg and 50kg of water.

[0045] Prepare liquid alkali-free and chlorine-free quick-setting agent according to above-mentioned raw material formula, comprise the steps:

[0046] (1) Weigh coagulation accelerator, coagulation accelerator early strength agent, early strength agent, complexation accelerator, stabilizer, inorganic acid, defoamer and water according to the above formula and mix according to the following steps, including:

[0047] First take water and add it to the reaction kettle and heat it to 40°C, start the mixer, control the stirring speed to 40r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com