Alkali and chlorine free liquid setting accelerator

A quick-setting agent and liquid technology, applied in the field of building materials, can solve problems that affect the health of construction workers, damage to the internal structure of concrete, cracks or cracks on the surface of concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

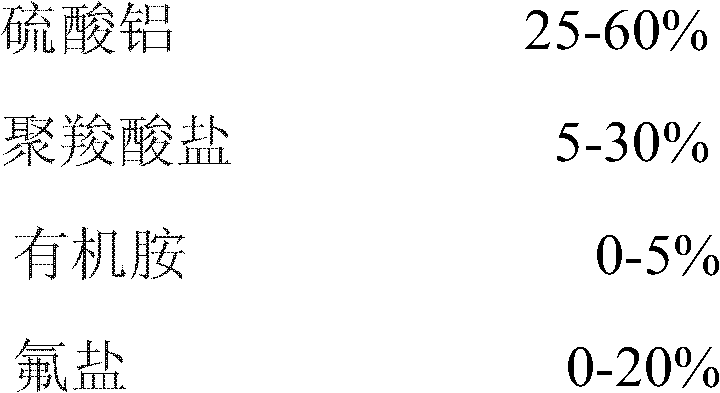

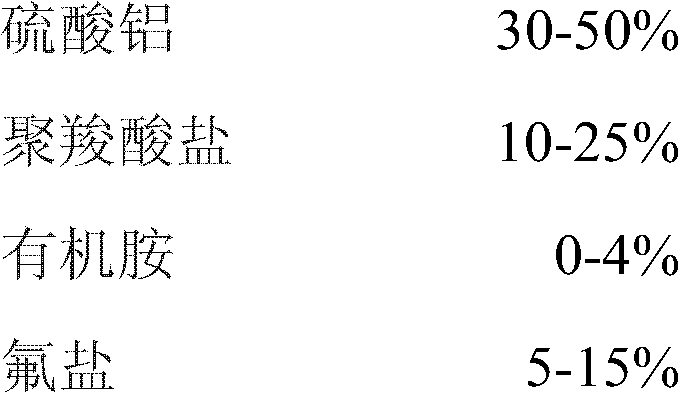

Method used

Image

Examples

Embodiment 1

[0023] According to the percentage by weight, 3% of diethanolamine, 27% of water, 40% of aluminum sulfate and 10% of magnesium fluorosilicate are added into the mixing container, and fully mixed evenly under stirring. Then heated to 50°C and stirred to completely dissolve the solid. Turn off the heating source, add 20% polycarboxylate high-efficiency superplasticizer and mix evenly, and cool to normal temperature to obtain a high-performance alkali-free and chlorine-free liquid accelerator.

[0024] According to the JC477-2005 test method, the "Western House" brand OP42.5 ordinary Portland cement produced by Sichuan Yedong Cement Co., Ltd. was used. Add the alkali-free and chlorine-free liquid quick-setting agent prepared above by 4% of the cement weight. When the water-cement ratio is 0.4, the initial setting time is 2 minutes and 40 seconds, and the final setting time is 5 minutes and 53 seconds.

[0025] The prepared mortar is: sand: cement: water=3:2:1, the compressive s...

Embodiment 2

[0027] In percentage by weight, 5% of diethanolamine, 25% of water, 55% of aluminum sulfate and 10% of magnesium aluminum fluoride are added into the mixing container, and fully mixed evenly under stirring. Heat to 75°C with stirring to completely dissolve the same body. Turn off the heating source, add 5% polycarboxylate high-efficiency superplasticizer and mix evenly, and cool to normal temperature to obtain a high-performance non-alkali and chlorine-free liquid over-coagulant.

[0028] According to the JC477-2005 test method, the "Stone Forest" brand OP52.5 benchmark cement produced by Yunnan State-owned Dongjun Cement Co., Ltd. was used. Add the alkali-free and chlorine-free liquid quick-setting agent prepared above by 5% of the cement weight. When the water-cement ratio is 0.4, the initial setting time is 3 minutes and 37 seconds, and the final setting time is 8 minutes and 25 seconds.

[0029] The prepared mortar is: sand: cement: water=3:2:1, 24 hours compressive stre...

Embodiment 3

[0031] According to weight percentage, add 2% of diethanolamine, 20% of water, 60% of aluminum sulfate and 13% of sodium fluoride into the mixing container, and fully mix evenly under stirring. Heat to 90°C with stirring to completely dissolve the solid. Turn off the heating source, add 5% polycarboxylate high-efficiency superplasticizer and mix evenly, and cool to room temperature to obtain a high-performance and environmentally friendly alkali-free and chlorine-free liquid accelerator.

[0032] According to the JC477-2005 test method, the "Yu Wang" brand OP42.5 ordinary Portland cement produced by Shanxi Hejin Cement Co., Ltd. was used, and the alkali-free and chlorine-free liquid quick-setting agent prepared above was mixed with 3% of the cement weight. When the water-cement ratio is 0.38, the initial setting time is 3 minutes and 42 seconds, and the final setting time is 7 minutes and 44 seconds.

[0033] The prepared mortar is: sand: cement: water=3:2:1, the 24-hour comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com