Control method of specific surface area of moderate heat cement

A specific surface area and control method technology, applied in the field of building materials, can solve the problem of high specific surface area, achieve the effect of improving grinding efficiency, ensuring stability, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Since the grindability of medium-heat clinker is worse than that of ordinary clinker, in order to strengthen the crushing capacity of the first warehouse, the effective length of the cylinder of the cement mill in this embodiment is 13.31 meters, and the effective length of the first warehouse is 3.78 meters. , in order to ensure the stability of the medium-heat cement quality, so that it can be fully ground in the second warehouse, the effective length of the second warehouse is set to 2.91 meters, and the effective length of the third warehouse is set to 6.62 meters; The slit width of the material grate plate is 9 mm, and the width of the slit of the discharge grate plate is 4.5 mm; 1mm wide. The grading scheme is shown in Table 1:

[0017] Table 1

[0018]

[0019] Send medium-heat cement clinker and gypsum with an average particle size of 25 mm into the cement mill for open-circuit high-fine grinding, adjust the air door of the exhaust fan to 40% opening, and t...

Embodiment 2

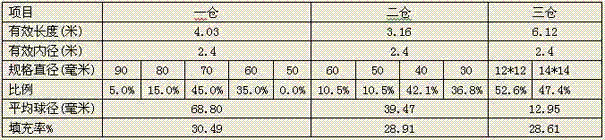

[0021] The effective length of the first chamber of the cylinder of the cement mill in this embodiment is 4.03 meters, the effective length of the second chamber is set to 3.16 meters, and the effective length of the third chamber is set to 6.12 meters; The slit width of the grate plate is 10mm, and the slit width of the discharge grate plate is 5mm; mm. The grading scheme is shown in Table 2:

[0022] Table 2

[0023]

[0024] Send medium-heat cement clinker and gypsum with an average particle size of 24 mm into the cement mill for open-circuit high-fine grinding, adjust the air door of the exhaust fan to 60% opening, and the output at the console is 35 tons / hour, which can be obtained Moderate heat cement with a specific surface area of 280 m2 / kg.

Embodiment 3

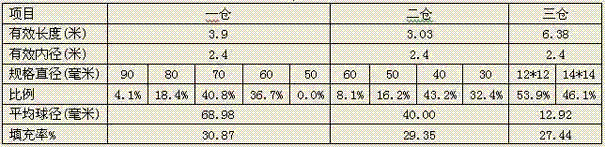

[0026] The effective length of the first chamber of the cylinder of the cement mill in this embodiment is 3.90 meters, the effective length of the second chamber is set to 3.03 meters, and the effective length of the third chamber is set to 6.37 meters; The slit width of the grate plate is 10 mm, and the slit width of the discharge grate plate is 5 mm; mm. The grading scheme is shown in Table 3:

[0027] table 3

[0028]

[0029] Send medium-heat cement clinker and gypsum with an average particle size of 24 mm into the cement mill for open-circuit high-fine grinding, adjust the air door of the exhaust fan to 50% opening, and the output at the console is 32 tons / hour, which can be obtained Moderate heat cement with a specific surface area of 300 m2 / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com