Method for recovering nonferrous metals, rare and noble metals and iron powder from steelmaking flue dust

A technology for non-ferrous metals and rare and precious metals, which is applied in the field of rare and precious metals and iron powder, recycling non-ferrous metals, and can solve the problem of low comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

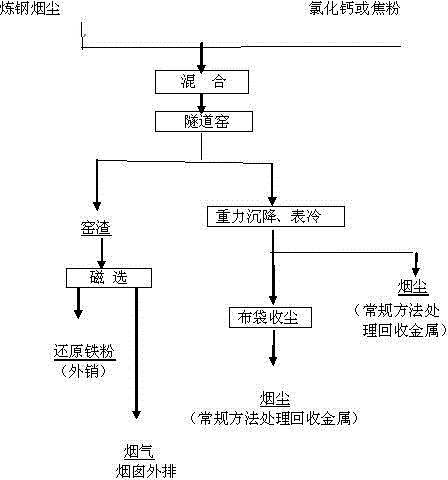

[0010] See attached figure 1 , using the steelmaking fume produced by the steelmaking furnace of Kunming Iron and Steel Holding Co., Ltd., its chemical composition is (Wt%): Zn 24.52 , Pb 4 , Fe 26 , S 0.5, In 0.02, Ag 0.01, Bi 0.4, Sn 0.5Au 0.00008 , the process is as follows:

[0011] 5000 kg of steelmaking dust, liquid chlorinating agent (a mixture of calcium chloride and sodium chloride 10-12:1) is added at a ratio of 50 kg; the reducing agent is coke powder, and the addition amount is 100 kg. Fully wet and mix in the barrel mixer so that the moisture content of the mixture is 4%, put it into the tunnel kiln, and the chemical reaction in it is carried out in two stages. The first stage is a medium temperature chlorination reaction, and the temperature is controlled at 1000-1050℃ After 100 minutes, non-ferrous metals, rare and precious metals Zn, Pb, Bi, Sn, In, Ge, Ag, Au, etc. in the steelmaking flue dust undergo chlorination reactions, and low-boiling chlorides volatil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com