Special bearing for speed reducer of vertical cement mill

A technology of reducer and vertical mill, which is applied in the direction of bearings, bearing components, roller bearings, etc., can solve the problems of reduced speed capacity, product failure, uneven force, etc., to reduce friction, improve high speed capacity, and benefit The effect of oil retention and lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

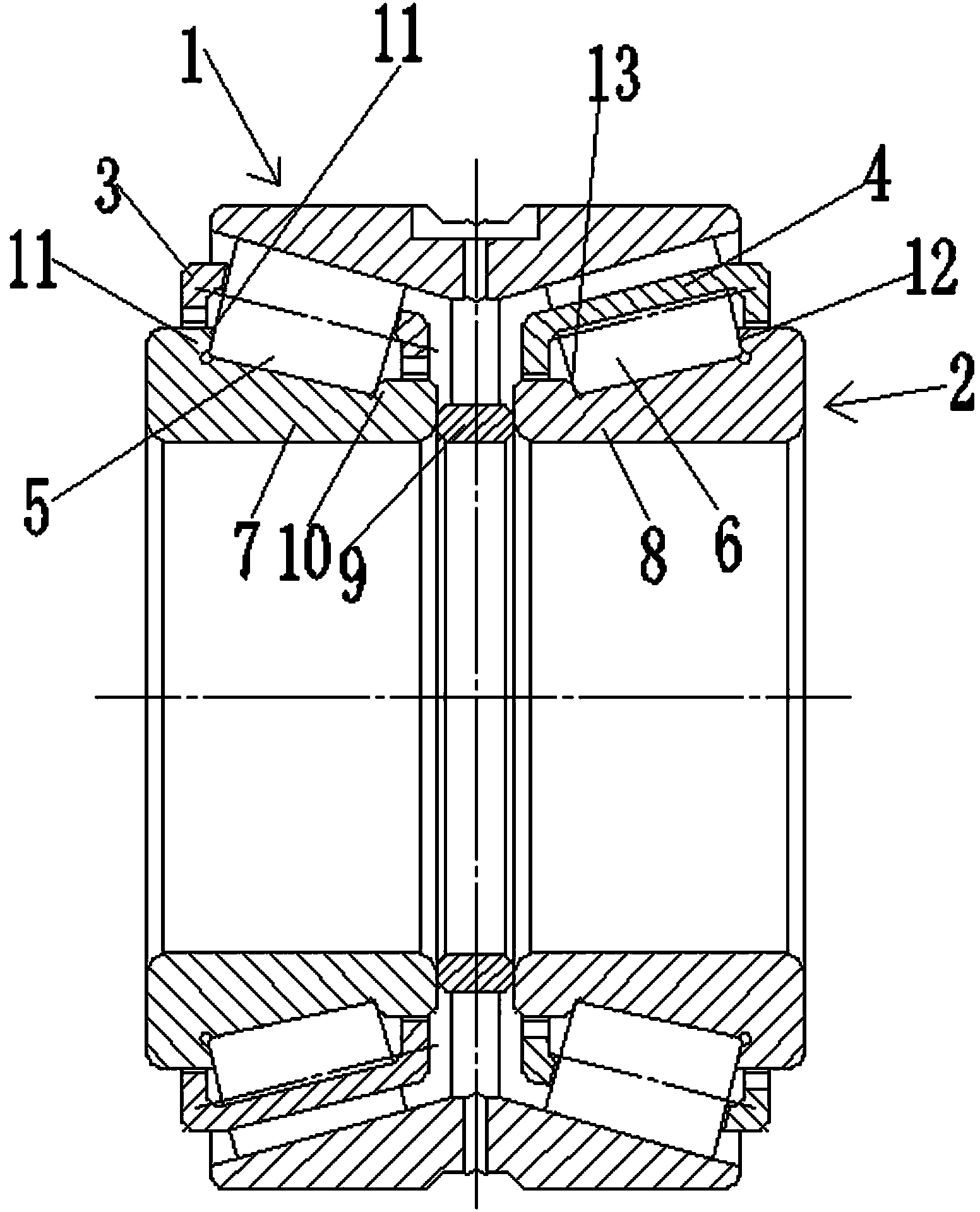

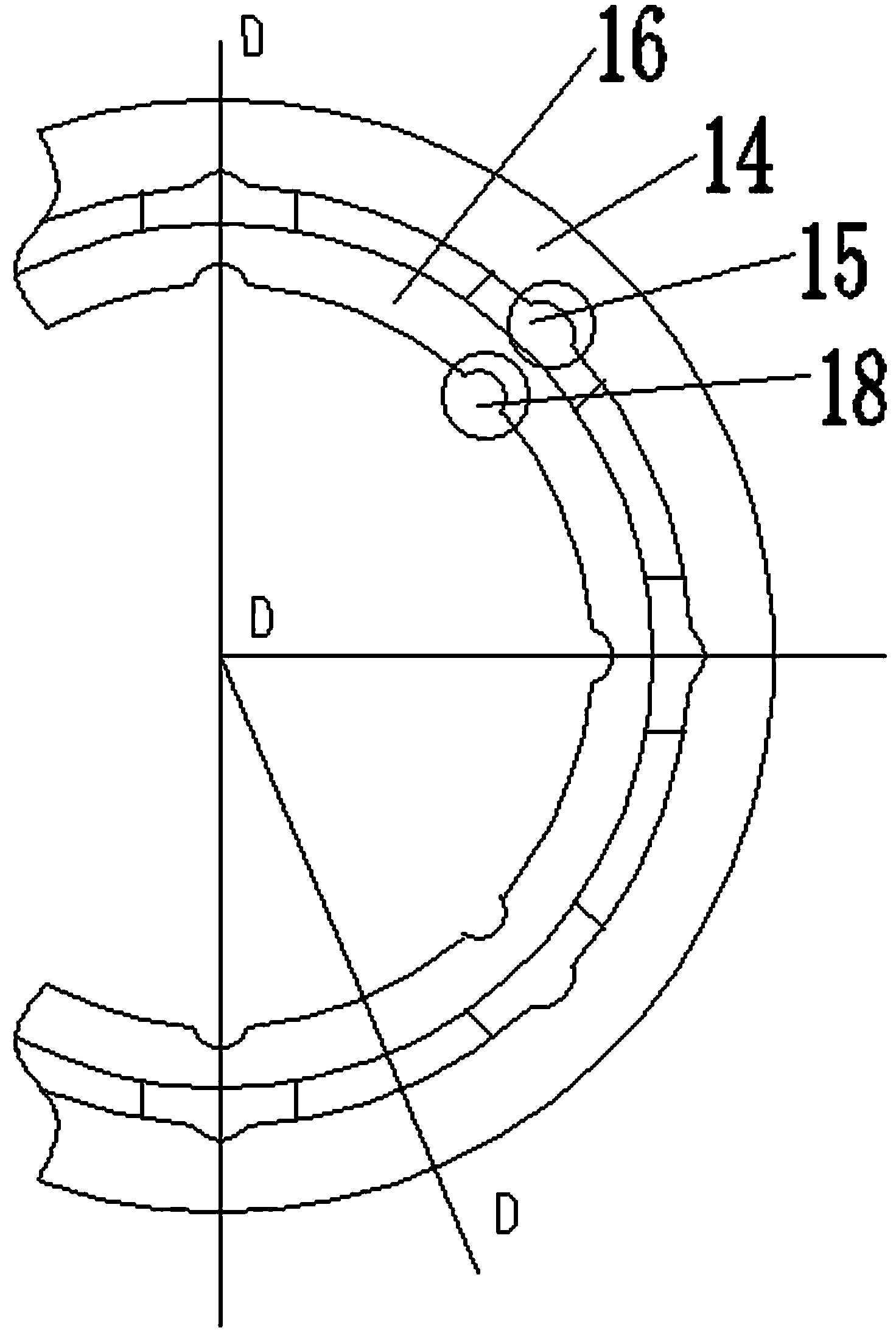

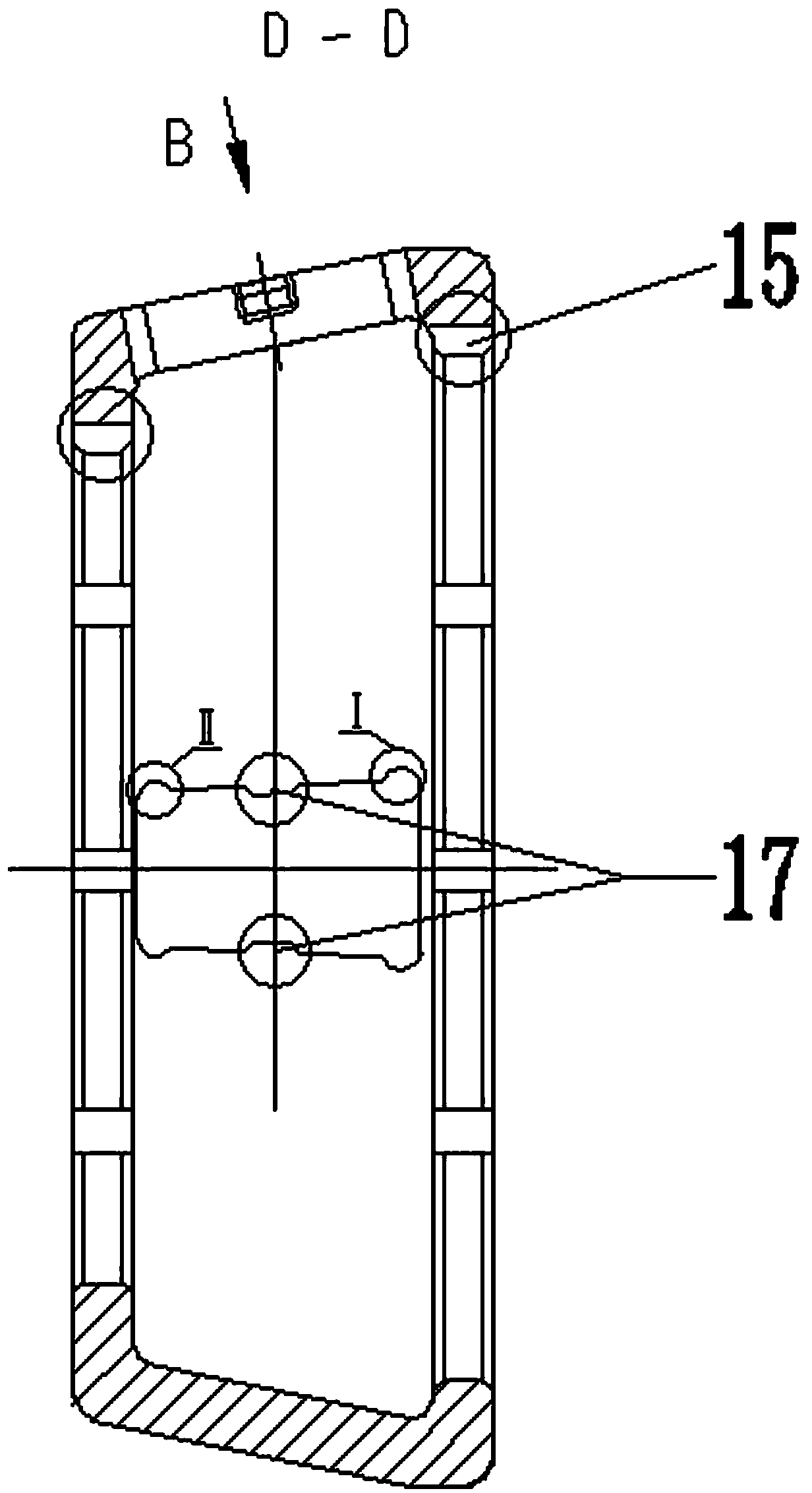

[0026] A special bearing for a cement vertical mill reducer, which is assembled from an outer ring 1, an inner ring 2, a first cage 3, a second cage 4, a first row of rolling elements 5 and a second row of rolling elements 6, and is a Back-to-back double row tapered roller bearings, characterized by:

[0027] ① The inner ring 2 is composed of the first half inner ring 7 and the second half inner ring 8, an inner spacer ring 9 is arranged between the first half inner ring 7 and the second half inner ring 8, and the rolling elements are tapered rollers.

[0028] ②The large rib 11 and the small rib 10 of the first half inner ring 7 are consistent with the inner diameter guide gap of the first cage, and the large rib 11 and the small rib 10 of the first half inner ring 7 guide the first cage .

[0029] The large rib 12 and the small rib 13 of the second half inner ring 8 are consistent with the guide gap of the inner diameter of the second cage, and the large rib 12 and the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com