Improved cement grinding aid

A cement grinding aid, enhanced technology, applied in the field of enhanced cement grinding aids, can solve the problems of cement and concrete durability safety hazards, unstable grinding aid quality, cement quality fluctuations, etc., to increase the scope of use , increase the output per hour, and improve the effect of grinding aid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

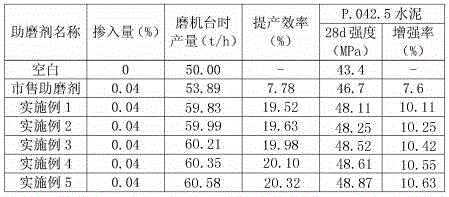

Examples

Embodiment 1

[0009] An enhanced cement grinding aid, which consists of the following components in parts by weight: 15 parts by weight of triethanolamine, 8 parts of polytetrafluoroethylene, 6 parts of propylene glycol, 5 parts of xanthan gum, 10 parts of sodium nitrite, 8 parts of wood calcium, 10 parts of sodium acetate, water retention Material 10, papermaking black liquor 10, industrial salt 12, molasses 10, the above raw materials were mixed and stirred for 30 minutes to obtain the product of the present invention.

Embodiment 2

[0011] An enhanced cement grinding aid, consisting of the following components in parts by weight: 25 triethanolamine, 2 polytetrafluoroethylene, 3 propylene glycol, 2 xanthan gum, 5 sodium nitrite, 3 wood calcium, 5 sodium acetate, water retention Material 5, papermaking black liquor 5, industrial salt 6, molasses 5, and the above raw materials were mixed and stirred for 30 minutes to obtain the product of the present invention.

Embodiment 3

[0013] An enhanced cement grinding aid, consisting of the following components in parts by weight: 18 triethanolamine, 6 polytetrafluoroethylene, 5 propylene glycol, 4 xanthan gum, 9 sodium nitrite, 7 wood calcium, 8 sodium acetate, water retention Material 8, papermaking black liquor 8, industrial salt 10, molasses 8, and the above raw materials were mixed and stirred for 30 minutes to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com