Method for preparing high-calcium fly-ash cement with high-calcium fly-ash

A high-calcium fly ash and cement technology, applied in cement production and other directions, can solve the problems that the fly ash humidity control process is not easy to operate, not easy to automate operations, and the cost of modified fly ash is high. The effect of preventing paste bags and reducing the cost of cement manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Cement clinker is a high-quality clinker produced by a high-quality rotary kiln production line.

[0030] Natural gypsum: should meet the gypsum or anhydrite of Class G or Class A (inclusive) and above specified in GB / T 5483. Industrial by-product gypsum: a by-product with calcium sulfate as the main component in industrial production. When using industrial by-product gypsum, it must be tested to prove that it is harmless to water performance.

[0031] The slag is the granulated blast furnace slag in accordance with GB / T203.

[0032] High calcium ash is desulfurized high calcium ash produced by desulfurization and calcium increase of thermal power plant fly ash or low calcium fly ash with calcium oxide content greater than 10%.

[0033] The digestion agent is the liquid or solid free calcium oxide digestion material described in Patent Application No. 200810017534.X. Implementation steps:

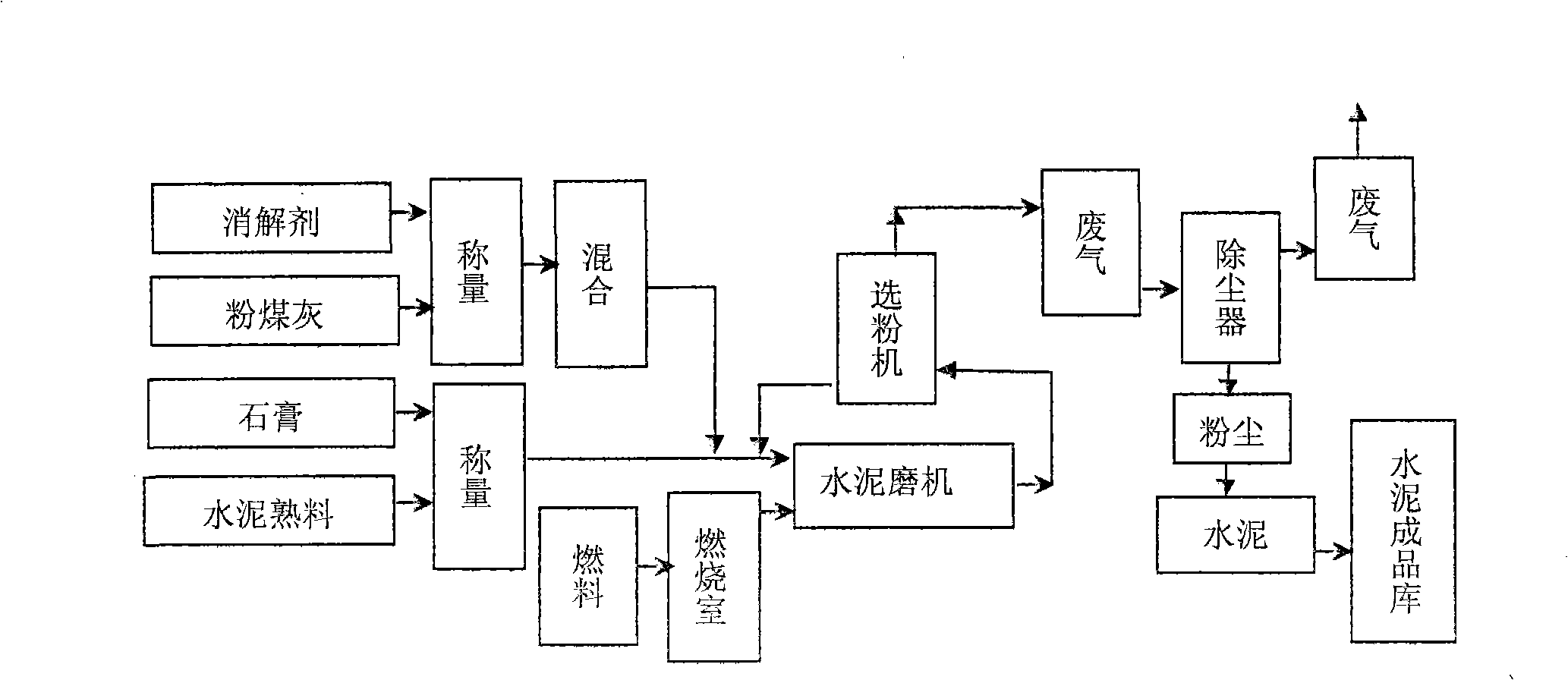

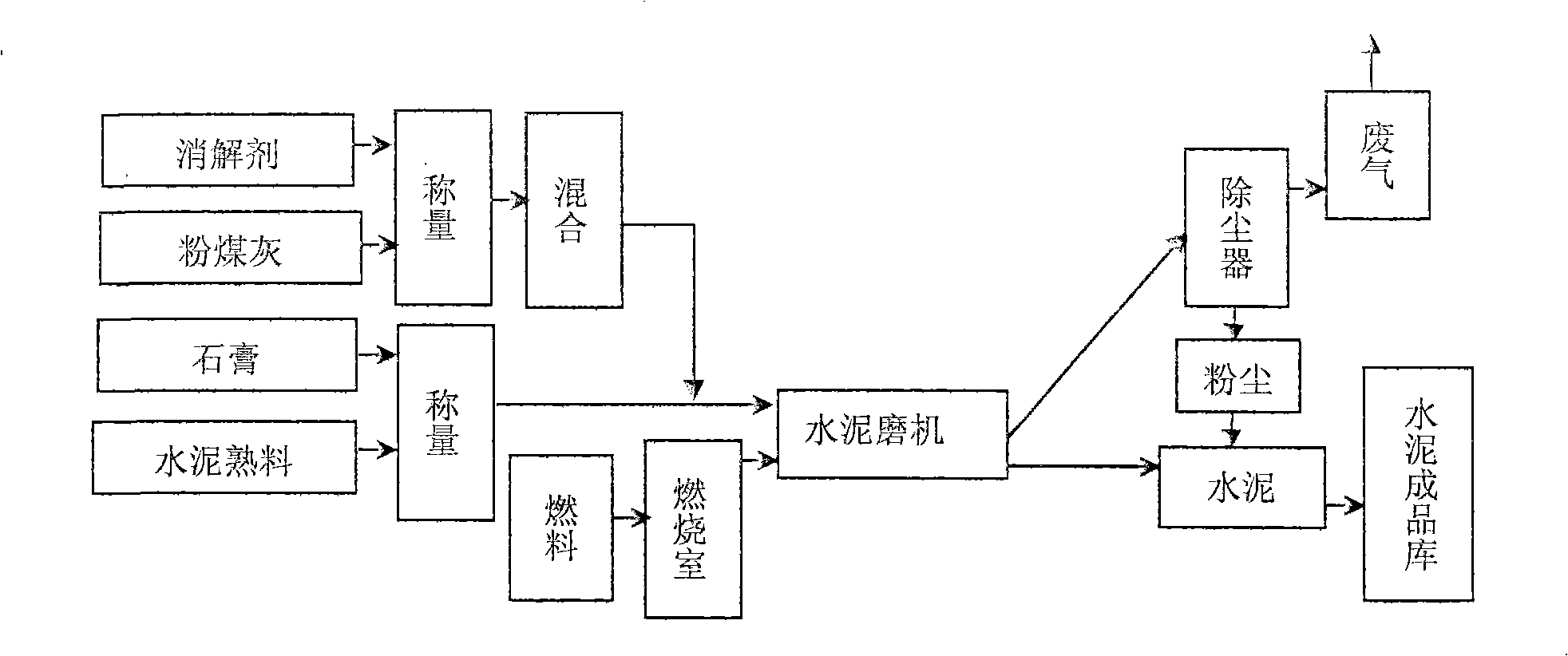

[0034] (1), at first, a combustion chamber is set at the head of the existin...

Embodiment 2

[0039] 70 parts of cement clinker; 20 parts of high-calcium fly ash; 5 parts of gypsum; 5 parts of blast furnace slag; plus 1 part of the weight of high-calcium fly ash as a disintegrant; The sieve residue of the grinding particle size of 45 microns is less than 15%, and the obtained fly ash cement meets the indicators specified in GB 1344-1999 "National Standard for Slag Portland Cement, Pozzolanic Portland Cement and Fly Ash Portland Cement" , and other steps are the same as in Example 1.

Embodiment 3

[0041] Cement clinker: 65 parts; high-calcium fly ash 25 parts; gypsum 5 parts; blast furnace slag: 5 parts; additional digestion agent is 1.5 parts by weight of high-calcium fly ash; The sieve residue of cement grinding particle size of 45 microns is less than 15%, and the obtained fly ash cement meets the requirements of GB 1344-1999 "National Standard for Slag Portland Cement, Pozzolanic Portland Cement and Fly Ash Portland Cement". index, other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com