On-line high-pressure water washing method for rotary air preheater of full-bag dust removal coal-fired boiler

A technology for bag dust removal and coal-fired boilers, which is applied in the direction of flushing, combustion technology relief, and cleaning of heat transfer devices. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

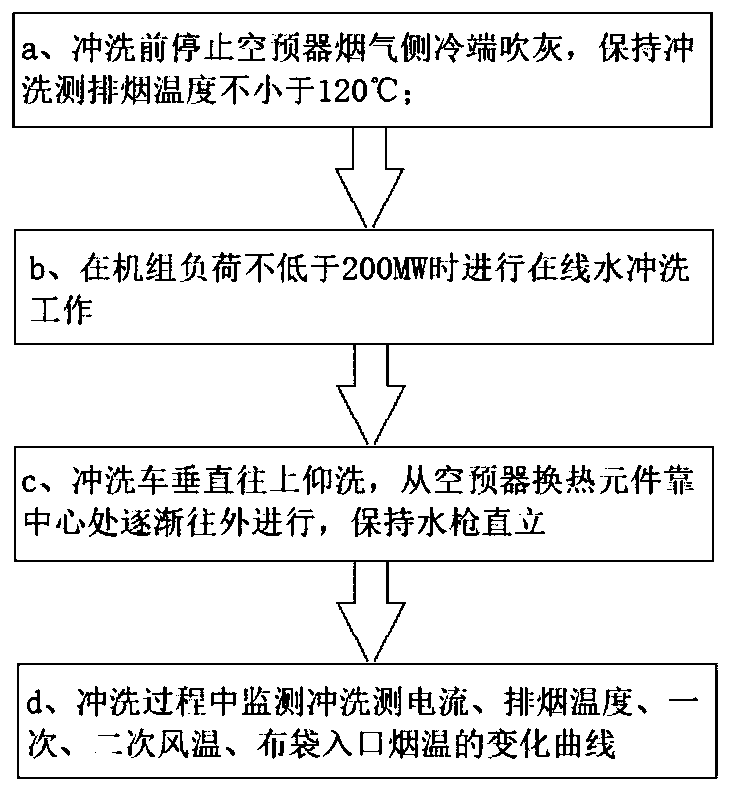

[0036] The online high-pressure water flushing method for the rotary air preheater of the full-bag dedusting coal-fired boiler in this embodiment is carried out according to the following steps:

[0037] a. Preliminary preparation, stop soot blowing at the cold end of the flue gas side of the air preheater before flushing to ensure a high exhaust gas temperature, and keep the exhaust gas temperature of the air preheater during flushing not less than 120°C; thus ensuring flushing water and evaporation And control the humidity of the flue gas to prevent the bag filter from sticking to the bag;

[0038] b. Check that the current of the air preheater is normal. When the load of the unit is not less than 200MW, carry out online water flushing of the air preheater; The opening of the induced draft fan blades should be appropriately increased to ensure that the furnace pressure is maintained at -50Pa; the operating load of the unit should not be too low during flushing, so as to prev...

Embodiment 2

[0046] The on-line high-pressure water flushing method for the rotary air preheater of the full-bag dedusting coal-fired boiler in this embodiment is basically the same as that in Embodiment 1, except that the opening of the rotor vane of the induced draft fan on the flushing side is adjusted before flushing in step b of this embodiment. Turn it down by 10%, increase the opening of the fan blade on the other side, and maintain the furnace pressure at -100Pa; the temperature of the flushing water used is 30°C; when flushing in step c, the flushing water gun is stepped back from the inside to the outside by 2cm each time, The dwell time at the innermost flushing position is 4 minutes, and every time you step back 15 times, increase the flushing time by 2.5 minutes, and observe the pressure difference change after flushing, and adjust the flushing time in each area.

Embodiment 3

[0048] The on-line high-pressure water flushing method for the rotary air preheater of the full-bag dedusting coal-fired boiler in this embodiment is basically the same as that in Embodiment 1, except that the opening of the rotor vane of the induced draft fan on the flushing side is adjusted before flushing in step b of this embodiment. Turn it down by 6%, increase the opening of the fan blade on the other side, and maintain the furnace pressure at -80Pa; the temperature of the flushing water used is 20°C; when flushing in step c, the flushing water gun is stepped back from the inside to the outside by 3cm each time, The dwell time at the innermost flushing position is 6 minutes, and every time you step back 25 times, increase the flushing time by 2 minutes, and observe the pressure difference change after flushing, and adjust the flushing time in each area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com