A preparation method of glass fiber membrane-coated filter material with antistatic denitrification function

A technology of glass fiber and film-coated filter material, which is applied in the direction of separation methods, membrane filters, chemical instruments and methods, etc., can solve the problems of easy generation of static electricity, poor abrasion resistance and folding resistance of glass fiber, and avoid sticky bags, Effect of improving wear resistance and good heat resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

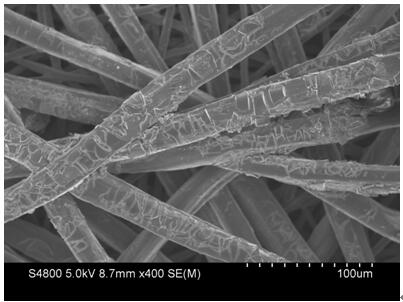

Image

Examples

preparation example Construction

[0025] A preparation method of a glass fiber membrane-coated filter material with antistatic denitrification function, comprising the following steps:

[0026] Step 1. Preparation of denitrification functional composite graphite finishing solution

[0027] 11) Ultrasonic cleaning and vacuum drying of 2000-4000 mesh graphite powder to obtain graphite powder. The graphite powder is immersed in an acid treatment solution with a mass concentration of 15-35% at a mass volume concentration of 50-70g / L. Reflux at 80-90°C for 4-6h, cool to room temperature after the reflux, then wash with deionized water and ethanol several times, dry in vacuum at 70-75°C for 10-12h, and set aside;

[0028] 12) Add the dried product obtained in step 11) to a certain concentration of catalyst solution, heat and stir at 50-60°C until it becomes a gel, then put it in an oven for 10-12 hours at 80-90°C, and finally put it in Roasting at 350-400°C for 2-4 hours in a muffle furnace to obtain denitrificatio...

Embodiment 1

[0040] A preparation method of a glass fiber membrane-coated filter material with antistatic denitrification function, comprising the following steps:

[0041] Step 1, preparing denitrification composite graphite finishing solution

[0042] 11) Ultrasonic cleaning of 2000-4000 mesh graphite powder with deionized water at 35°C for 20 minutes, vacuum drying at 70°C for 2 hours, and immersion of the dried graphite powder into a mass concentration of 15-35 % acid treatment solution, reflux at 80°C for 4h, cool to room temperature after the reflux, then wash with deionized water for 3 times, wash with ethanol for 2 times, vacuum dry at 70°C for 10h, and set aside;

[0043] 12) Add the graphite powder prepared above into the catalyst solution with a certain mass concentration, heat and stir at 60°C until it becomes gelatinous, then put it in an oven for 12 hours at 80°C, and finally put it in a muffle furnace at 400°C Roasting for 2 hours to obtain denitrification functional graphi...

Embodiment 2

[0064] A preparation method of a glass fiber membrane-coated filter material with antistatic denitrification function, comprising the following steps:

[0065] Step 1. Preparation of denitrification composite graphite finishing solution

[0066] 11) Clean the 2000-mesh graphite powder ultrasonically with deionized water at 35°C for 20min, and vacuum-dry it at 70°C for 2h. Take 50g of the dried graphite powder and immerse it in 1L of acetic acid treatment solution with a mass fraction of 15%, at 80°C Reflux for 4 hours, cool to room temperature after the reflux, then wash with deionized water for 3 times, wash with ethanol for 2 times, dry in vacuum at 70°C for 10 hours, and set aside;

[0067] 12) Prepare a mixed solution of copper oxide and cerium oxide precursor nitrate containing 0.1g / ml, take 8ml of the solution and add it to 10g of the pretreated graphite powder in step 11), heat and stir at 60°C until it becomes gelatinous , and then placed in an oven for 12 hours at 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com