Sustained casing pressure diagnosis device and method

A technology of annulus under pressure and diagnostic device, which is applied in the direction of earthwork drilling, measurement, borehole/well components, etc., can solve problems such as leakage, loss of annular protection fluid, and failure of protection fluid protection, etc., to achieve easy promotion, The effect of preventing corrosion damage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

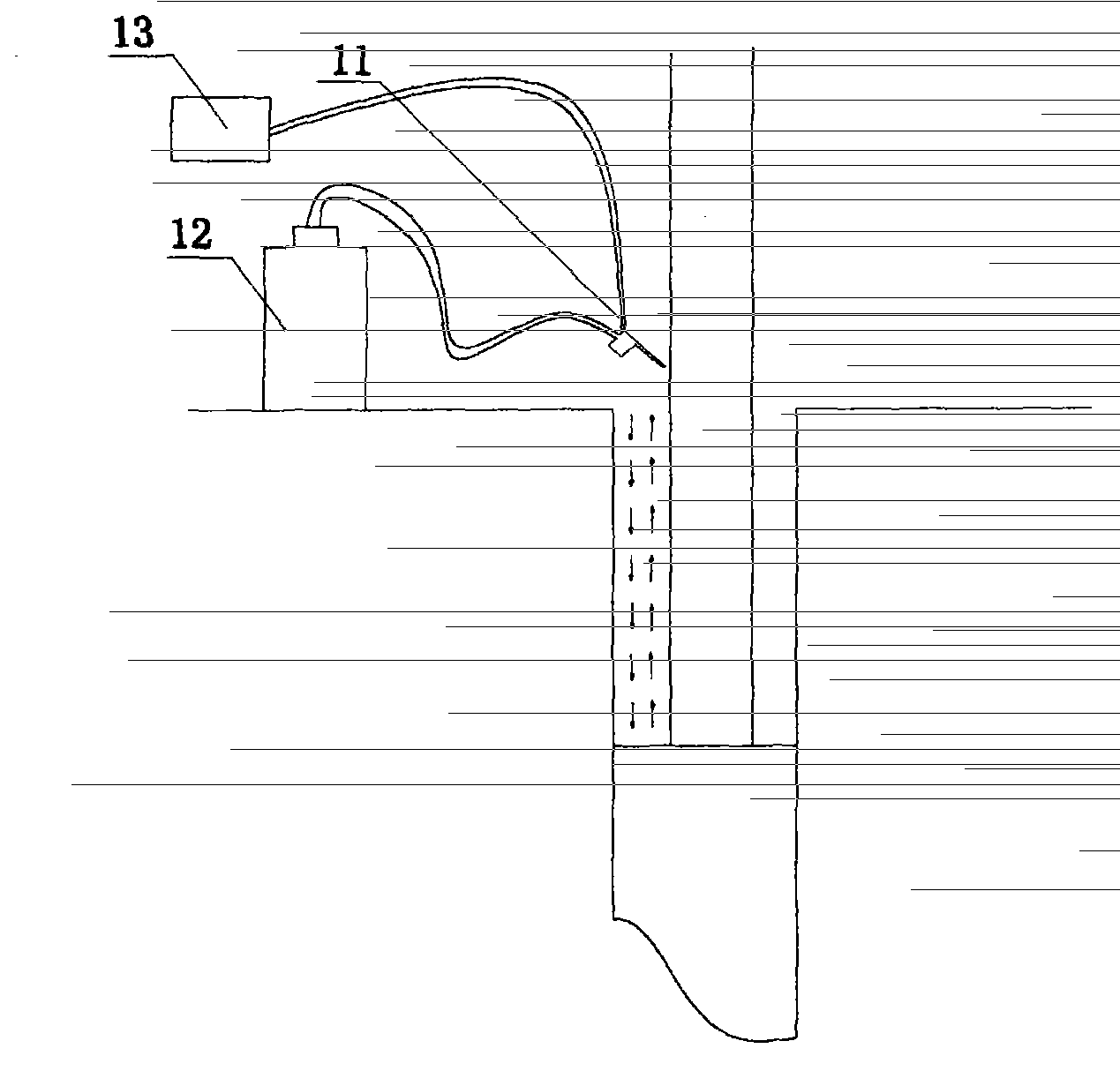

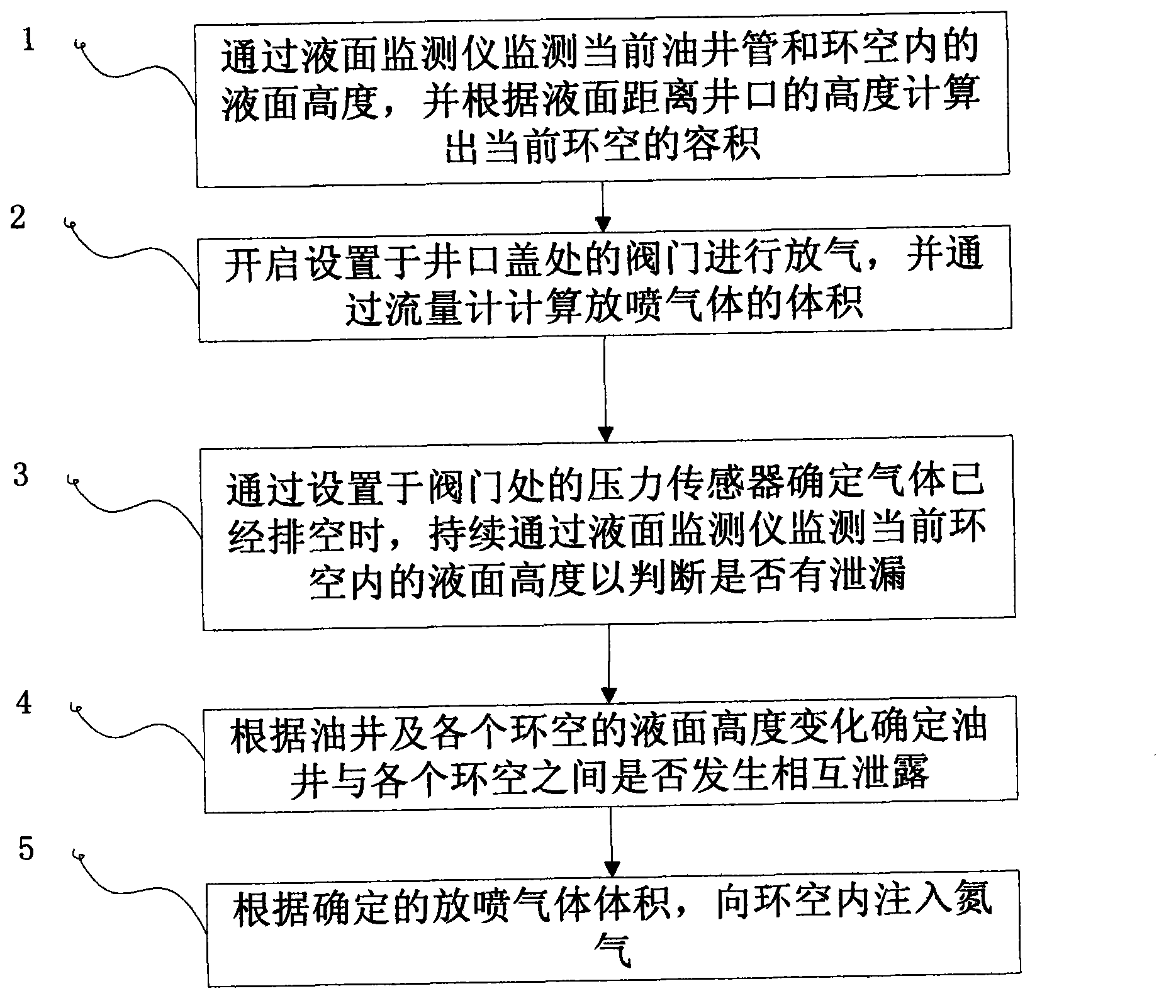

[0021] The preferred embodiment 1 of the present invention will be further described below in conjunction with the accompanying drawings.

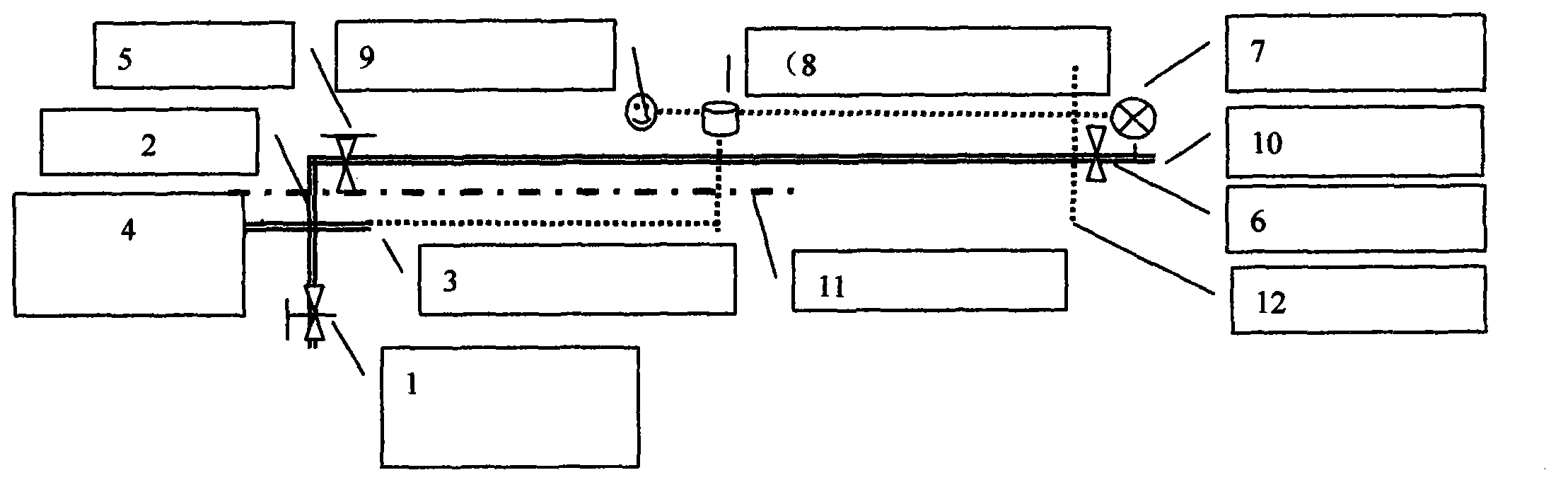

[0022] The present invention provides an annular pressure diagnostic device, which includes a pressure sensor for monitoring pressure and a flow meter for monitoring the discharge flow. Among them, a four-way connection is installed at the wellhead pressure Cock, which is connected to a firing gun for annulus liquid level monitoring, a pressure sensor for monitoring pressure, and a high-pressure pipeline valve for venting, and a high-pressure pipeline valve It is equipped with a flow meter and pressure sensor.

[0023] Such as figure 2 As shown, the system includes:

[0024] Cork 1: Diagnosis from this place, using the least wellhead equipment, the most convenient;

[0025] Stone 2: It must match the interface of Cork 1, usually AC high voltage buckle, or 1 / 2 "NPT buckle;

[0026] Pressure sensor 3: used to monitor wellhead casing pressure. Gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com