Method for observing microscopic structure of stainless steel

A technology for microstructure and stainless steel, applied in the field of observation of stainless steel microstructure, can solve problems such as difficult sample preparation, unreported application and development, complex adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

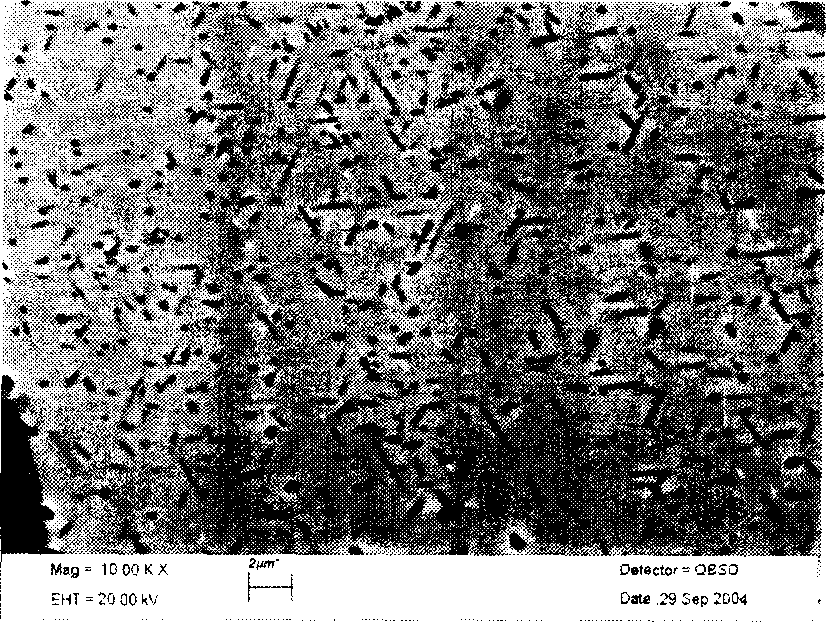

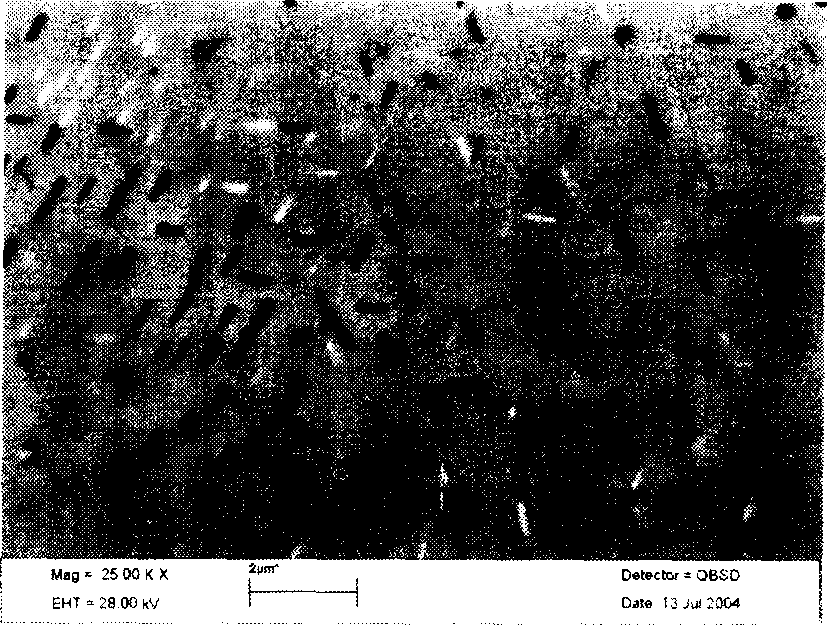

[0065] Example 1 Observation and Analysis of Dispersed Precipitated Phases in Stainless Steel

[0066] The stainless steel sample observed is 1Cr17Cu. Some fine and dispersed precipitates in stainless steel can only be observed by transmission electron microscope in the past. Using the microstructure observation method of the present invention, these precipitated phases can be clearly observed in a scanning electron microscope. In the development of antibacterial stainless steel, a very important link is the characterization and analysis of the microstructure of the sample after the aging treatment, focusing on the analysis of the presence or absence of ε-Cu phase precipitation, as well as the number, size and distribution of the precipitated phases. The observation method of the present invention is used to observe and analyze the ε-Cu phase in 1Cr17Cu under different solid solution and aging systems, which can replace part of the analysis work of the transmission electron micros...

Embodiment 2

[0096] Example 2 Analysis of the fine structure of the composite zone of the stainless steel composite plate

[0097] What is observed is the composite interface of ferritic stainless steel / carbon steel (0Cr13Al / 16MnR) composite plate. Because the corrosion resistance of stainless steel and carbon steel is very different, the metallographic erosion observation structure generally only erodes one side The structure, or the corrosion of stainless steel and carbon steel separately, has a greater impact on the observation of the structure of the bonding interface, and it is difficult to observe clear structure characteristics. This example is a polished backscattered electron crystal orientation contrast image of 0Cr13Al / 16MnR. Figure 4 It is a photo of the bonding area of ferritic stainless steel 0Cr13Al and 16MnR after explosive compounding, annealing heat treatment, electropolishing, and scanning electron microscope using backscattered electron detector. The bonding interface ar...

Embodiment 3

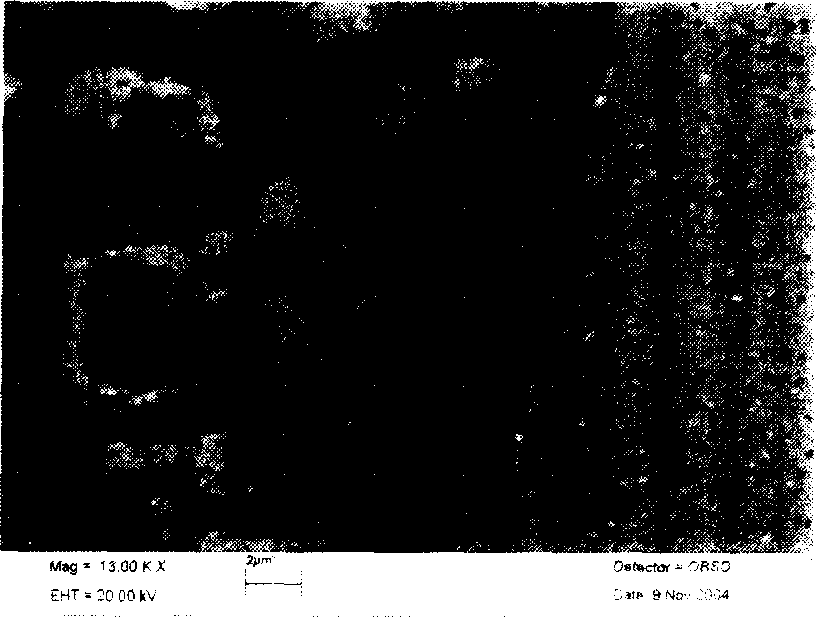

[0121] Example 3 Observation of Grain Boundary Carbides after Sensitization of Stainless Steel

[0122] The observation is 1Cr17Mn6Ni5N stainless steel. The carbide precipitated on the grain boundary of the stainless steel during use is the main cause of intergranular corrosion. The test of intergranular corrosion performance generally requires sensitization treatment on the sample, and the precipitated carbide should be corroded by metallography. Method is difficult to distinguish, because the carbide will fall off after the grain boundary is corroded. By adopting the scanning electron microscope observation method of the present invention, the precipitated carbides can be observed intuitively. Figure 5 It is the morphology of grain boundary carbides observed in the sensitized 1Cr17Mn6Ni5N stainless steel.

[0123] The steps are as follows:

[0124] 1. The preparation of the electrolytic polishing solution is the same as the first embodiment

[0125] 2. Sample processing and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com