Treatment method of ammonia nitrogen wastewater

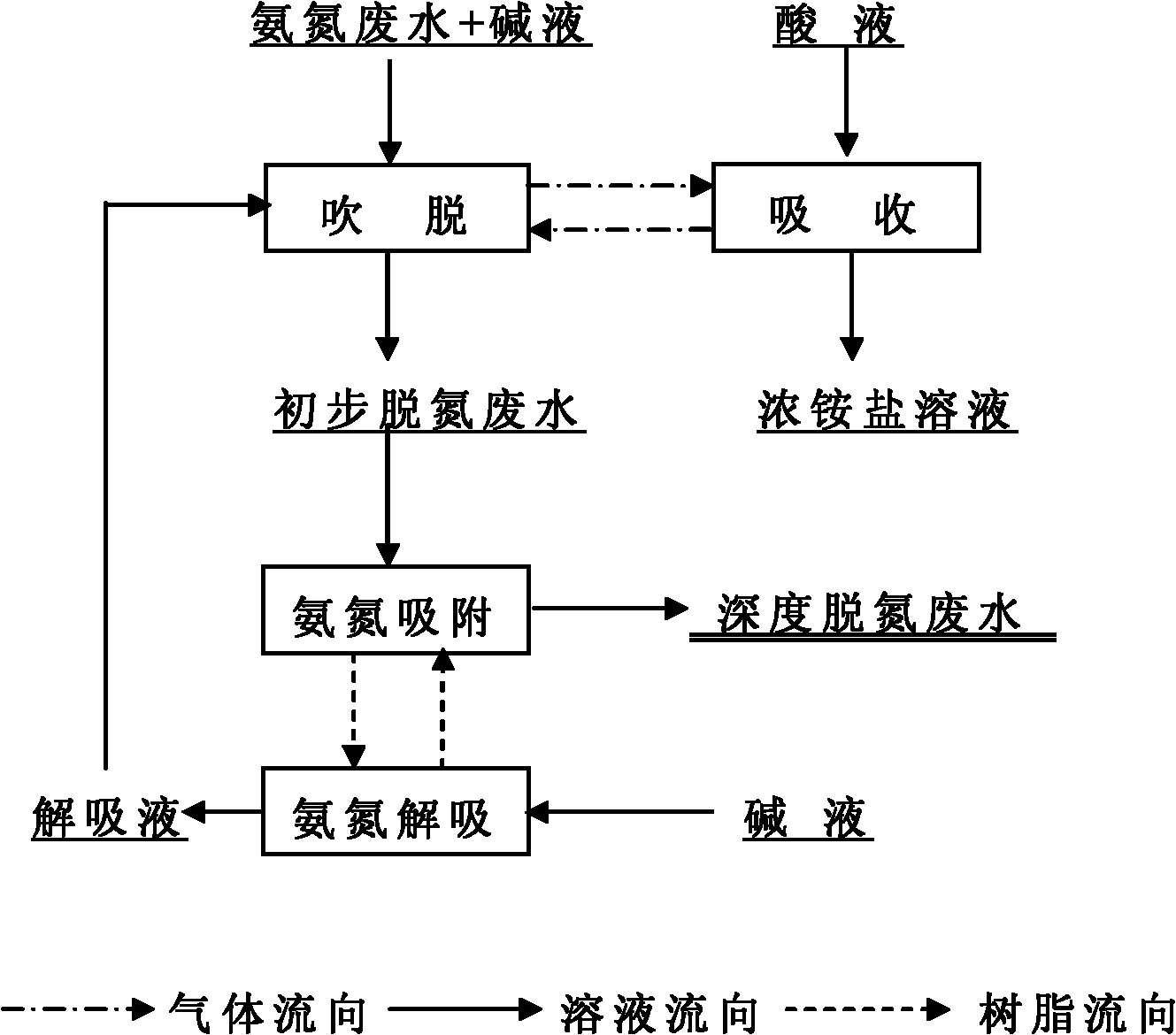

The technology of ammonia nitrogen wastewater and treatment method, which is applied in the field of environmental engineering, can solve the problems of high cost of chemicals, slow growth of nitrifying bacteria, large amount of resin, etc., and achieves good economic and environmental benefits, stable effluent quality, and reduced equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: At an ammonium sulfate concentration of 0.2mol / L, a sodium sulfate concentration of 1.0mol / L, and a volume of 6m 3 In the ammonium sulfate type ammonia nitrogen wastewater, add slaked lime Ca(OH) 2 About 2.6kmol, pH 10.5-12.0; CaSO 4 Sedimentation and separation to convert ammonium ions into NH 4 OH, waste water at 3m 3 The flow rate of / hr is sprayed into the packing volume about 4m 3 In the packed tower, the blowing flow is 12000hr / m at the same time 3 The air was circulated and blown off for 3 hours to obtain low-concentration ammonia nitrogen wastewater with an ammonia nitrogen concentration of 510mg / L. The stripped ammonia-containing gas is absorbed with sulfuric acid to obtain a saturated solution of ammonium sulfate, and the ammonium sulfate product is recovered after evaporation and concentration.

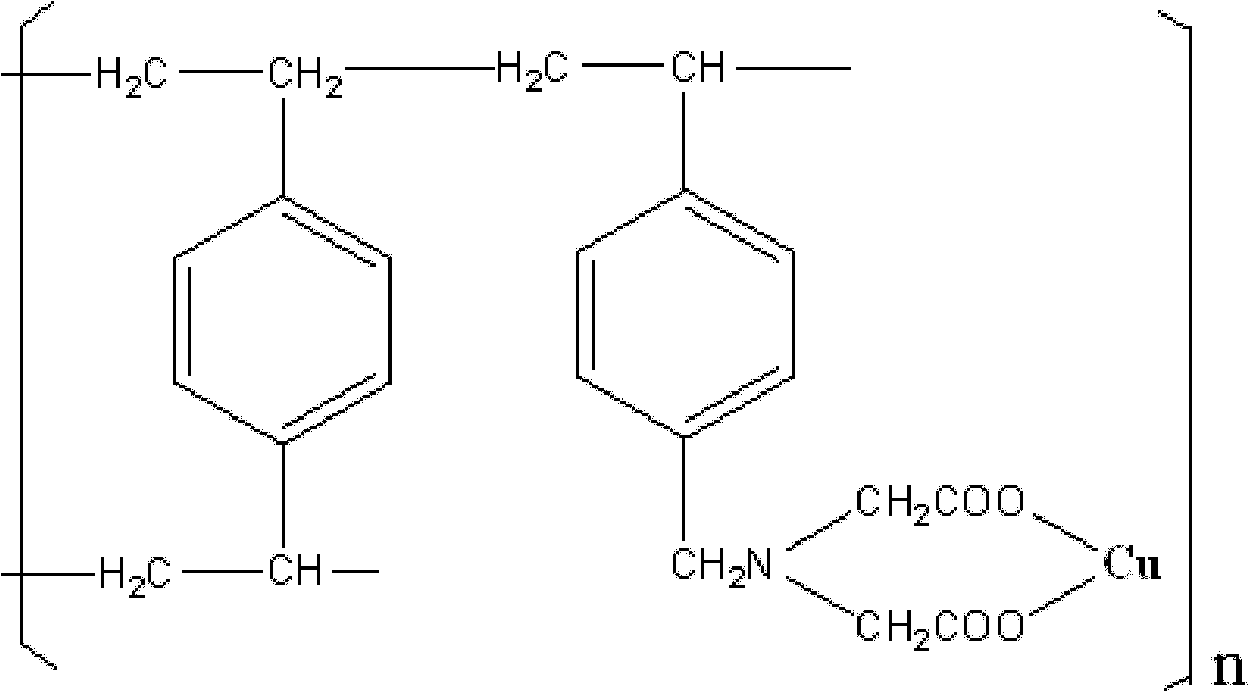

[0027] Step 2: Dispose of low-concentration ammonia nitrogen wastewater in 2m 3 / hr flow into the ammonia nitrogen adsorption resin 1m 3 In the ion-ex...

Embodiment 2

[0039] At a concentration of ammonium chloride of 0.4mol / L, a concentration of sodium chloride of 2.0mol / L, and a volume of 5m 3 In the ammonium chloride type ammonia nitrogen wastewater, add slaked lime Ca(OH) 2 About 2.6kmol and sodium carbonate 1.3kmol, pH 10.5-12.0; CaCO 3 Sedimentation and separation to convert ammonium ions into NH 4 OH, waste water at 3m 3 The flow rate of / hr is sprayed into the packing volume about 4m 3 In the packed tower, the blowing flow is 12000hr / m at the same time 3 The air was circulated and blown off for 3 hours to obtain low-concentration ammonia nitrogen wastewater with an ammonia nitrogen concentration of 560 mg / L. The stripped ammonia-containing gas is absorbed with sulfuric acid to obtain a saturated solution of ammonium sulfate, and the ammonium sulfate product is recovered after evaporation and concentration. Treat low-concentration ammonia-nitrogen wastewater with 2m 3 / hr flow into the ammonia nitrogen adsorption resin 1m 3 In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com