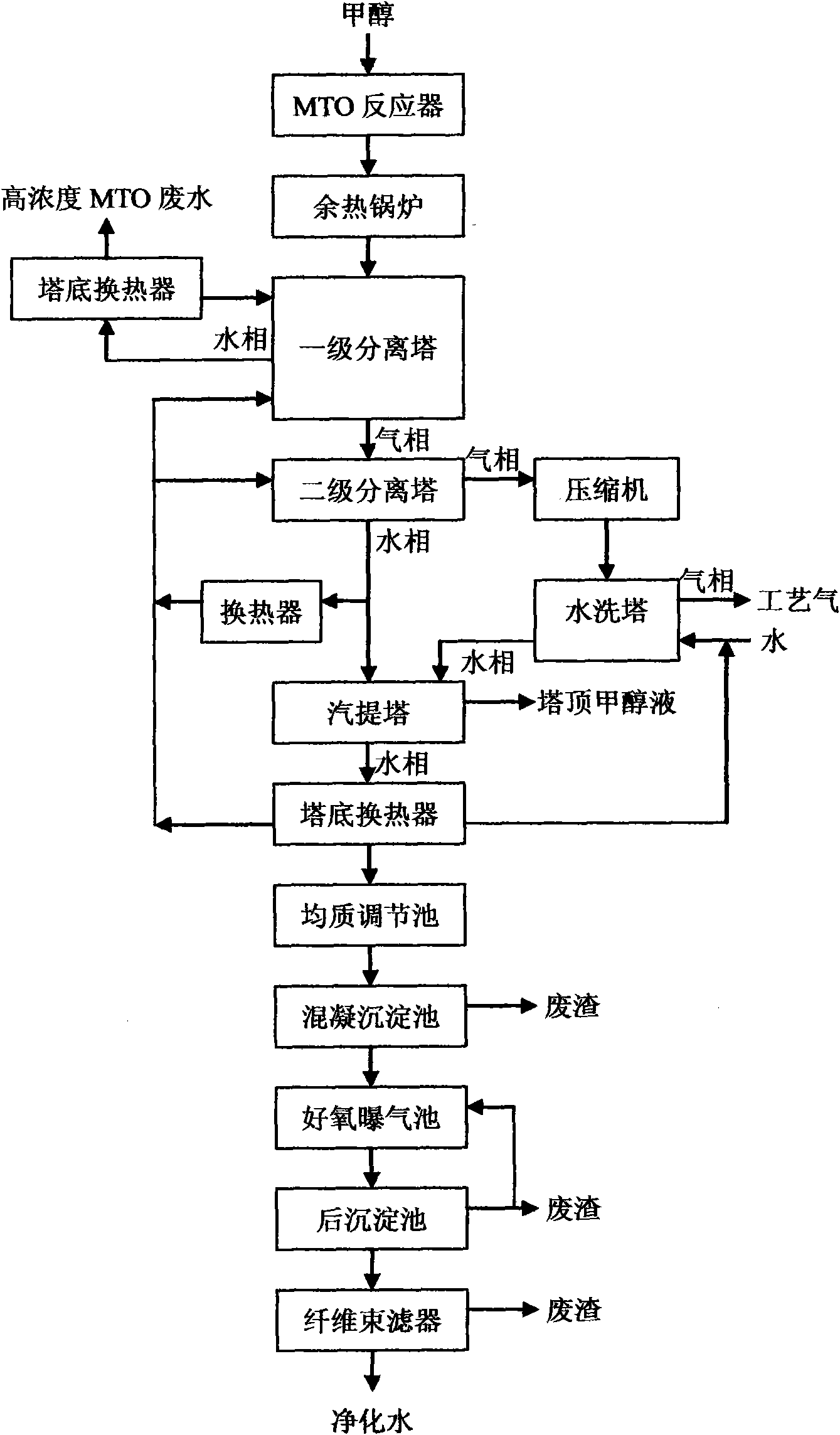

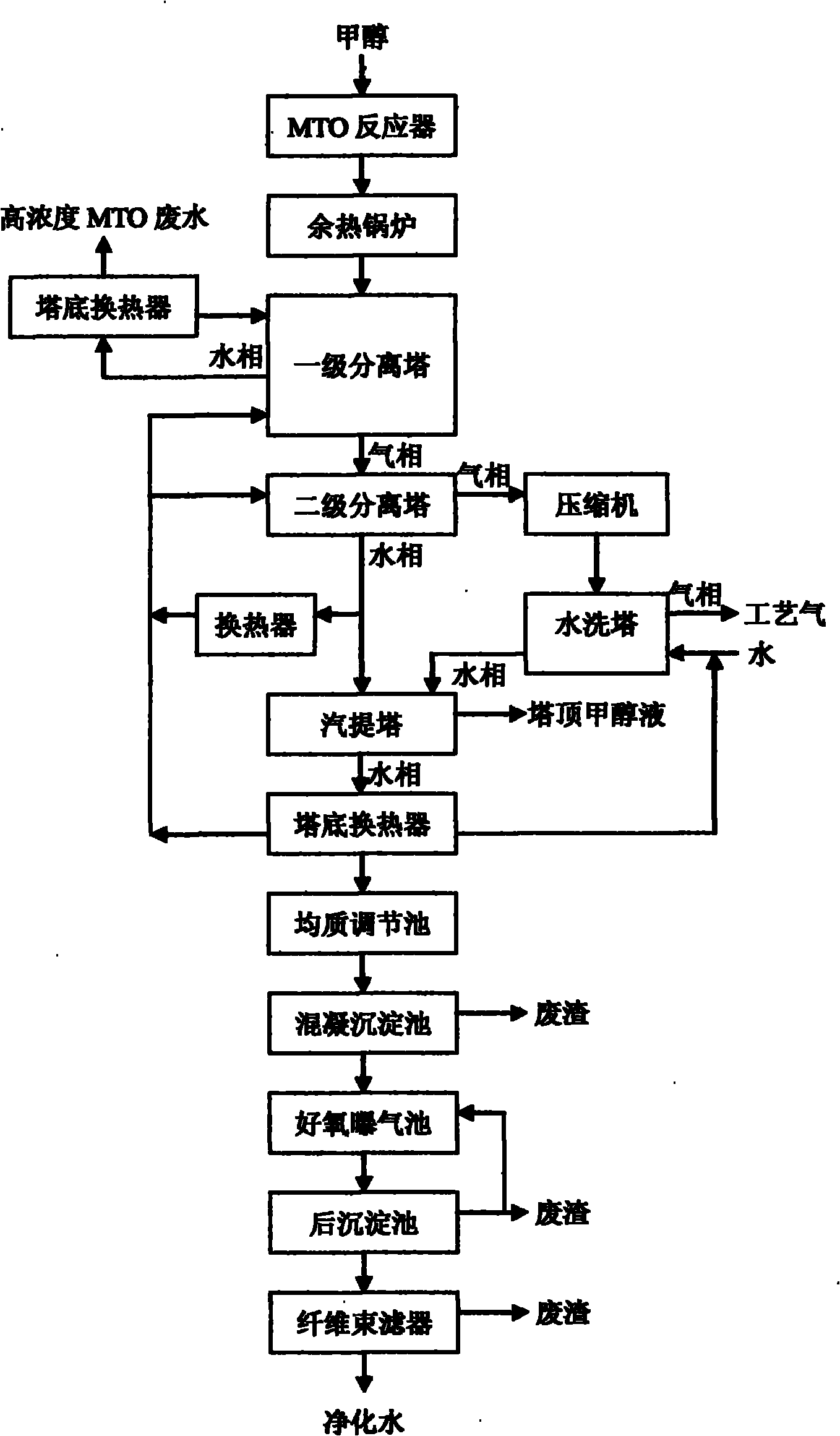

Treatment and reuse method of waste water in methanol-to-olefin process

A technology for methanol to olefins and waste water, which is applied in biological water/sewage treatment, degassed water/sewage treatment, water/sewage multi-stage treatment, etc. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Use the waste heat boiler to cool the effluent material of the MTO reactor at a temperature of 490°C to 190°C. Next, use water to directly cool the temperature of the MTO reactor effluent in the primary separation tower to reduce the temperature to 120°C. The water volume of the high-concentration MTO wastewater discharged after thermal cooling is 10% of the water volume generated by the MTO reaction.

[0055]In the secondary separation tower, continue to use water direct cooling to cool the effluent material of the MTO reactor that has separated high-concentration MTO wastewater. The cooling temperature is controlled at 118°C, so that most of the water and olefin gas are separated. In the separation tower The water phase is obtained at the bottom of the tower, and the olefin gas is obtained at the top of the separation tower. Part of the water phase at the bottom of the separation tower is cooled by heat exchange and used as cooling water for the effluent from the MTO ...

Embodiment 2

[0062] Use the waste heat boiler to cool the effluent material of the MTO reactor at a temperature of 460°C to 160°C. Next, use water to directly cool the temperature of the MTO reactor effluent in the primary separation tower to reduce the temperature to 115°C. The water volume of the high-concentration MTO wastewater discharged after thermal cooling is 20% of the water volume generated by the MTO reaction.

[0063] In the secondary separation tower, continue to use water direct cooling to cool the effluent material of the MTO reactor that has separated high-concentration MTO wastewater. The cooling temperature is controlled at 112°C, so that most of the water is separated from the olefin gas. In the separation tower The water phase is obtained at the bottom of the tower, and the olefin gas is obtained at the top of the separation tower. Part of the water phase at the bottom of the separation tower is cooled by heat exchange and used as cooling water for the effluent from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com