Ammonia nitrogen waste water discharge-reducing and ammonia nitrogen resource utilizing device and method

A technology of recycling ammonia nitrogen wastewater, applied in the direction of degassed water/sewage treatment, etc., can solve the problems of enterprises' reluctance, high steam unit consumption of ammonia nitrogen wastewater treatment, and inability to bear treatment costs, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

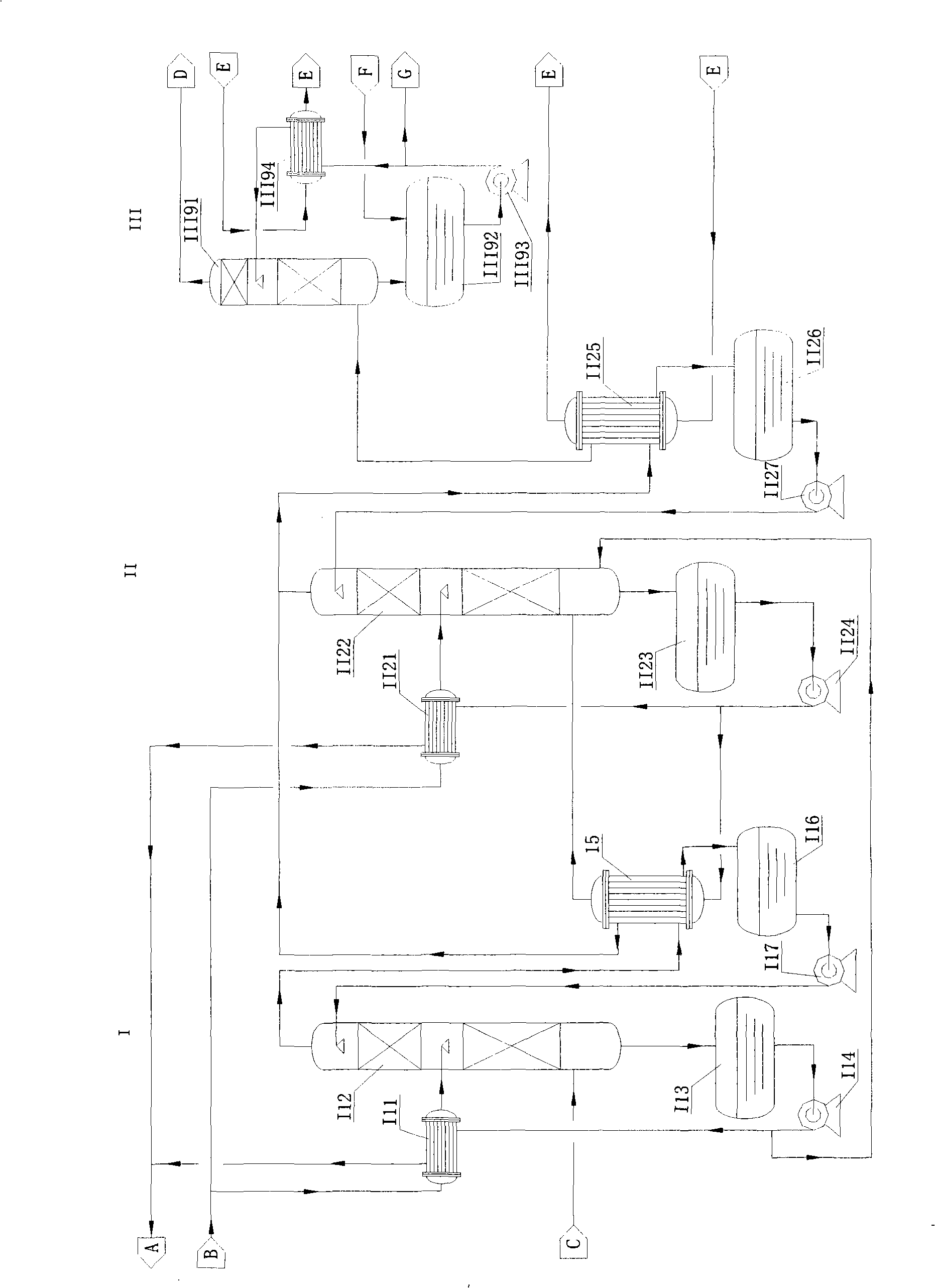

Embodiment 1

[0031] Ammonia nitrogen waste water is treated by adopting the secondary steam stripping deammonification of the present invention, the imported ammonia nitrogen concentration is 5000mg / L, and the treatment capacity is 10m 3 / h, respectively with a flow rate of 5.5m 3 / h and 4.5m 3 / h is sent to the primary and secondary stripping and deamination processes. In the first-stage stripping deamination process, waste water and the tower bottom liquid of the stripping deamination tower 12 enter the stripping section of the stripping deamination tower 12 after heat exchange in the raw material preheater 11, and rise from the bottom of the tower The steam is countercurrently contacted for mass exchange, and the ammonia in the wastewater enters the gas phase from the liquid phase. The waste water after the deamination enters the tower still liquid tank 13, and a part of the waste water in the tower still liquid tank 13 passes through the tower still liquid pump 14 with a flow rate of...

Embodiment 2

[0033] Ammonia nitrogen waste water is treated by secondary steam stripping and deammonification of the present invention, the imported ammonia nitrogen concentration is 30000mg / L, and the treatment capacity is 15m 3 / h, respectively with a flow rate of 8m 3 / h, 7m 3 / h is sent to the primary and secondary stripping and deamination processes. Its operation mode is identical with embodiment 1. In the ammonia nitrogen reuse process, the concentrated ammonia water with a concentration of 23% is obtained. Nessler's reagent colorimetric method (GB7479-87) was used for analysis, and the concentration of ammonia nitrogen in the treated wastewater was 9.5 mg / L (<15 mg / L, meeting the national primary discharge standard). The steam consumption is 115kg / ton of waste water.

Embodiment 3

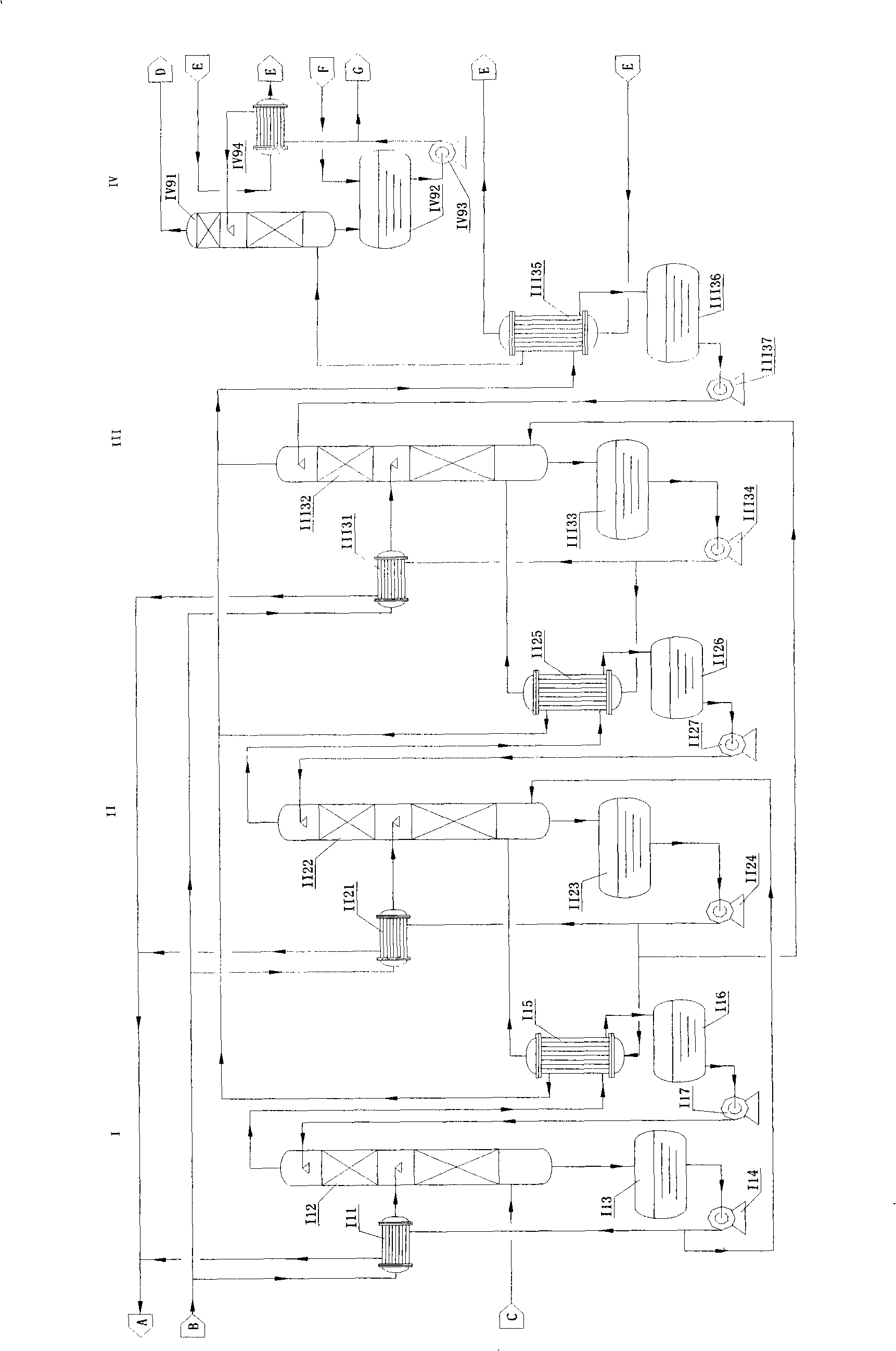

[0035] Ammonia nitrogen wastewater is treated by three-stage stripping and deammonification of the present invention, the imported ammonia nitrogen concentration is 60000mg / L, and the treatment capacity is 15m 3 / h, respectively with a flow rate of 6m 3 / h(40%), 5.1m 3 / h (34%) and 3.9m 3 / h (26%) is sent to the primary, secondary and tertiary stripping deamination process. Its operation mode is identical with embodiment 1. Ammonium sulfate with a concentration of 45% is obtained in the ammonia nitrogen reuse process. Nessler's reagent colorimetric method (GB7479-87) was used for analysis, and the concentration of ammonia nitrogen in the treated wastewater was 11.2 mg / L (<15 mg / L, meeting the national primary discharge standard). The steam consumption is 128kg / ton of waste water.

[0036] By adopting the process method of the present invention, the steam actually consumed in the treatment of ammonia-nitrogen wastewater is the steam introduced in the first-stage stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com