Method for producing environment-friendly rubber filling oil

A technology of rubber extender oil and production method, which is applied in the petroleum field, can solve the problems that it cannot be used as a substitute for rubber extender oil, low aromatic content, poor rubber compatibility, etc., and achieves good compatibility, high solvent recovery rate, and easy conditions Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

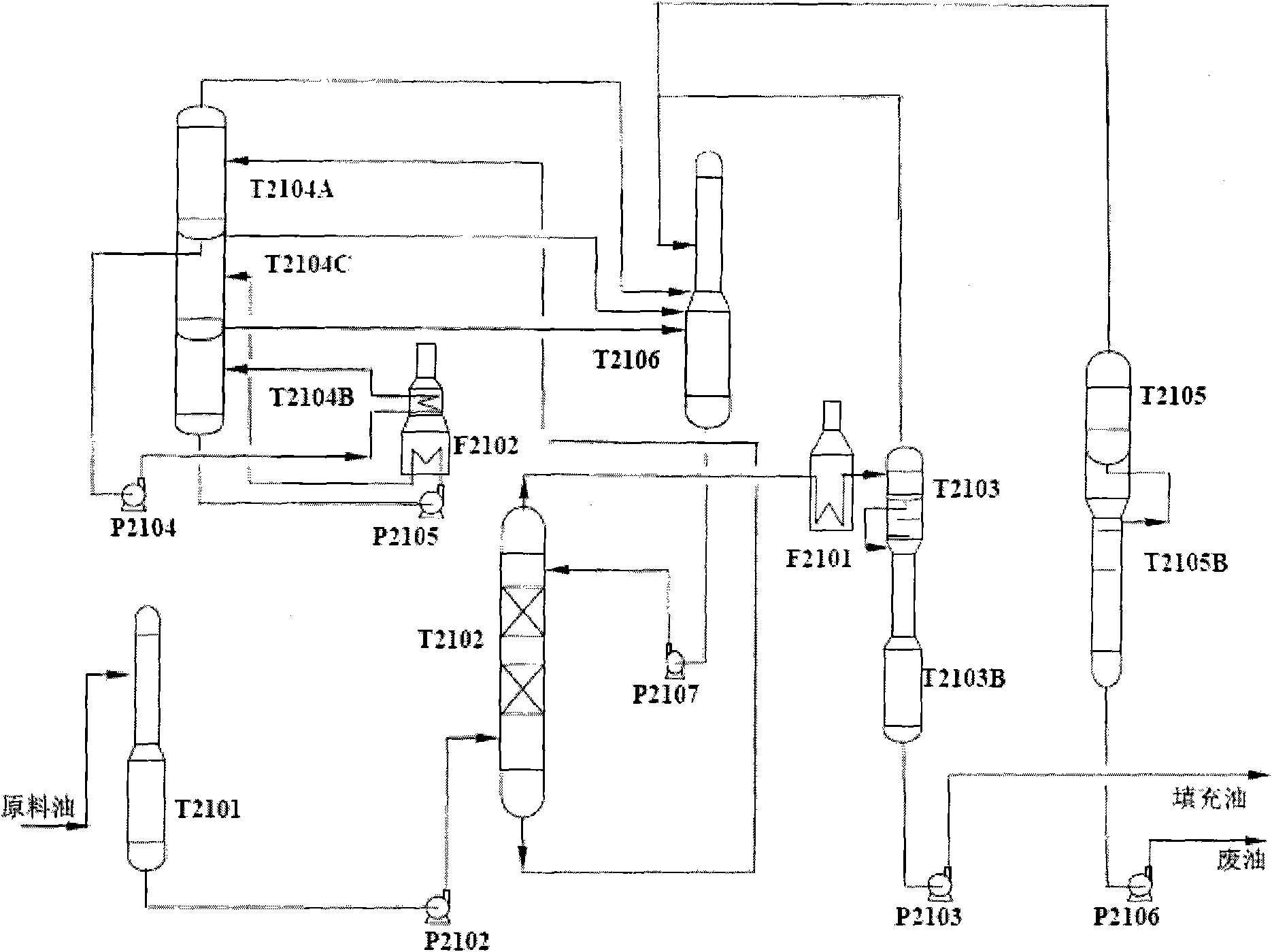

[0021] A production method of an environment-friendly rubber filler oil, the specific steps are: using the difference in specific gravity between the raw material oil and the solvent to carry out extraction in countercurrent full contact in the extraction tower, dissolving the polycyclic aromatic hydrocarbons in the raw material oil into the solvent, and It automatically settles to the bottom area of the tower, and the extracted raw material oil automatically rises to the top of the tower, and the solvent is recovered through the stripping process, and the entrained solvent is removed, which is the environmentally friendly rubber filler oil; the detailed process flow of the present invention is as follows:

[0022] See attached figure 1 , the raw oil enters the raw oil degassing tower (T2101) through heat exchange for vacuum stripping and degassing. The degassed raw material oil at the bottom of the degassing tower is pumped out by the pump P2102 at the bottom of the degassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com