Cycle closed type filler-free high-efficiency ammonia nitrogen removing and nutrient recovery device of biogas slurry

A recovery method and technology without filler, which is applied in the field of environmental protection and sewage treatment to achieve the effect of increasing the pH value, facilitating the removal of ammonia nitrogen and COD, and saving electricity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

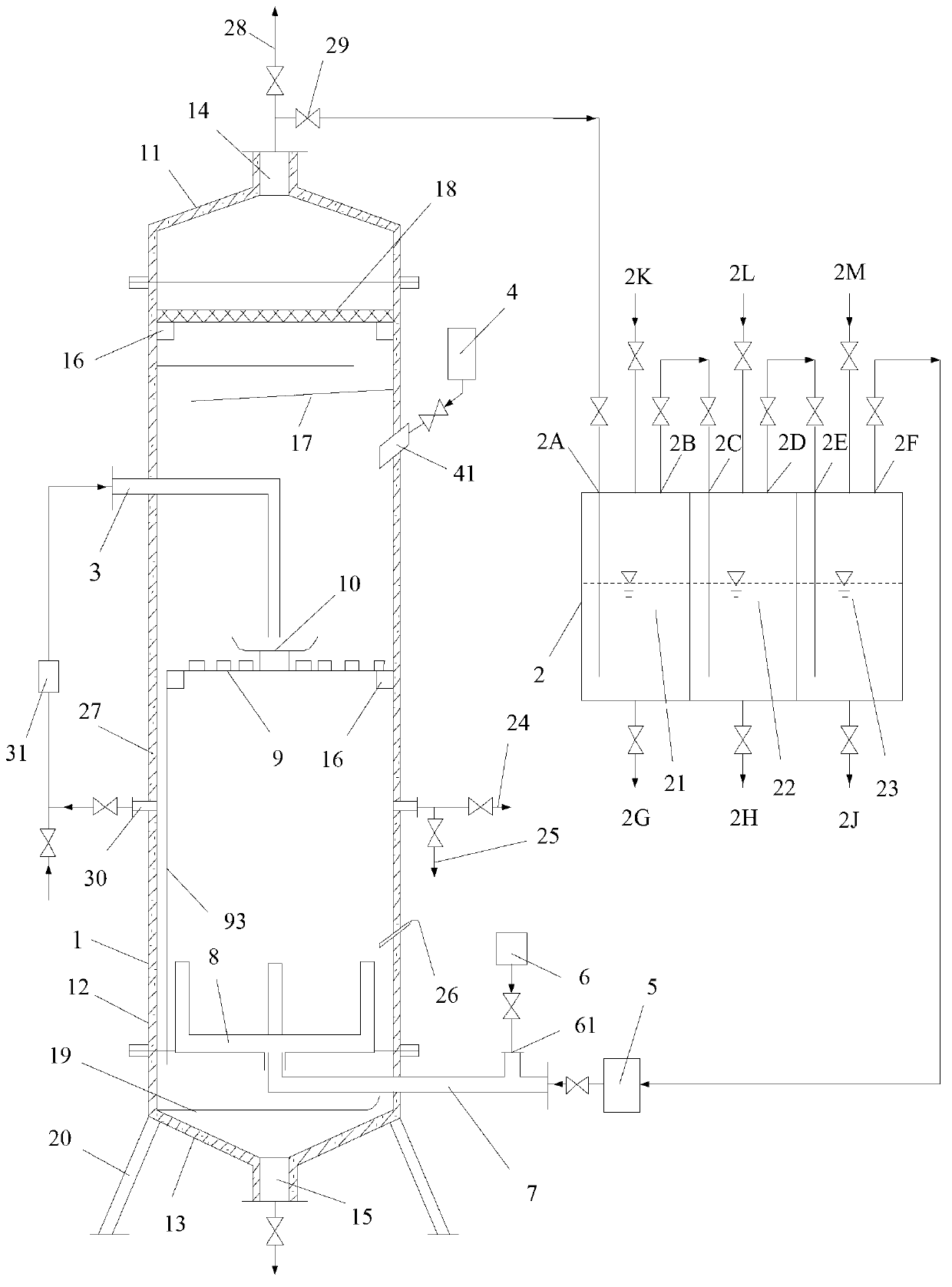

[0045] The method of the present invention will be further described in detail below in conjunction with accompanying drawing 1 and embodiments.

[0046] (1) When starting up, pump the biogas slurry to be treated into the stripping tower 1 through the biogas slurry reflux pump 35; fill the Ca(OH)2 solution into the alkali absorption tank 21, and fill 30 into the primary acid absorption tank 22 %H 2 SO 4 solution, to 98% concentrated sulfuric acid in the secondary acid absorption tank 23.

[0047] (2) Open the relevant valve, connect and form a gas circulation circuit, start the air pump, and the air flow rate is: 5L / min. The gas flows according to the following circulation path: degassing tower 1 headspace gas → suction port 14, valves and pipes → alkali absorption tank 21 inlet 2A → liquid in the alkali absorption tank 21 → alkali absorption tank 21 gas outlet 2B, valves and pipes →Inlet 2C of primary acid absorption tank 22→Liquid in primary acid absorption tank 22→Gas ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com