Well cementation cement sheath performance simulation experiment device and experiment method

A simulation experiment device and cementing technology, which is applied in construction and other fields, can solve problems such as imperfection, poor replacement efficiency of flushing fluid flushing process, and inability to truly simulate mud cake, etc., to achieve accurate simulation conditions, comprehensive functions, The experimental method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

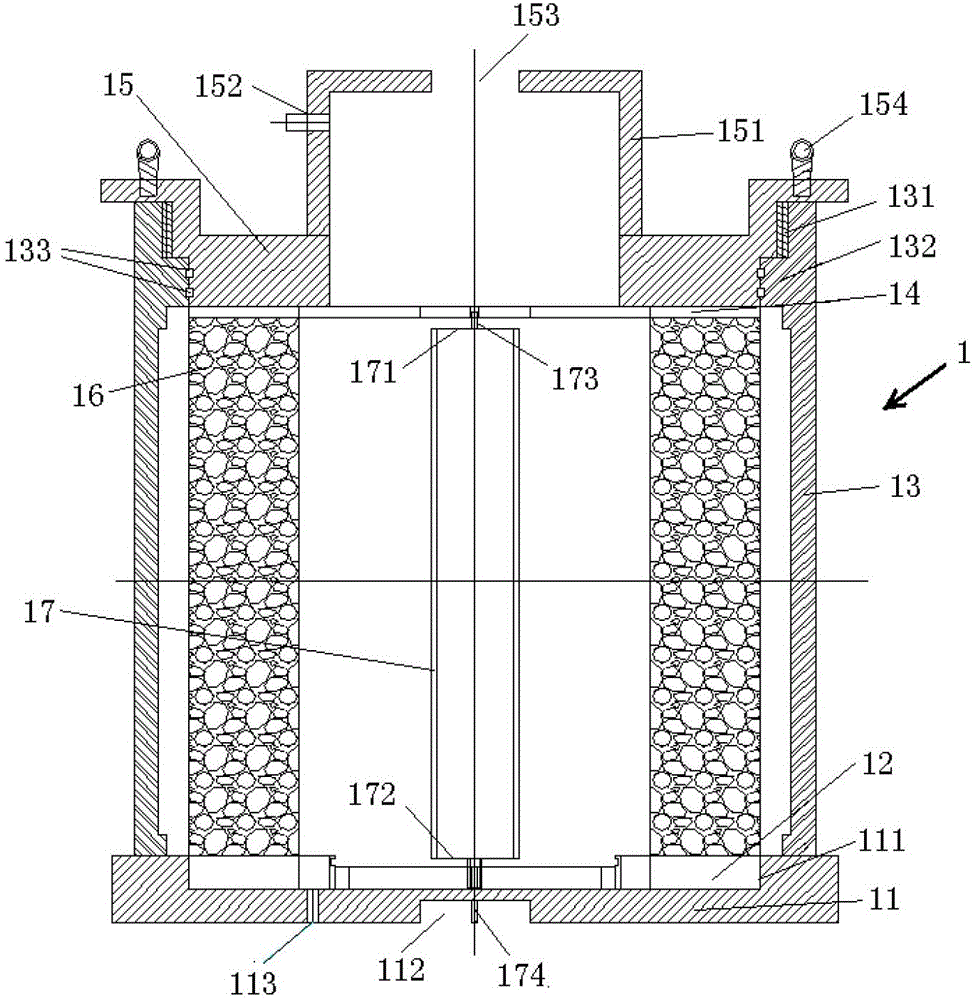

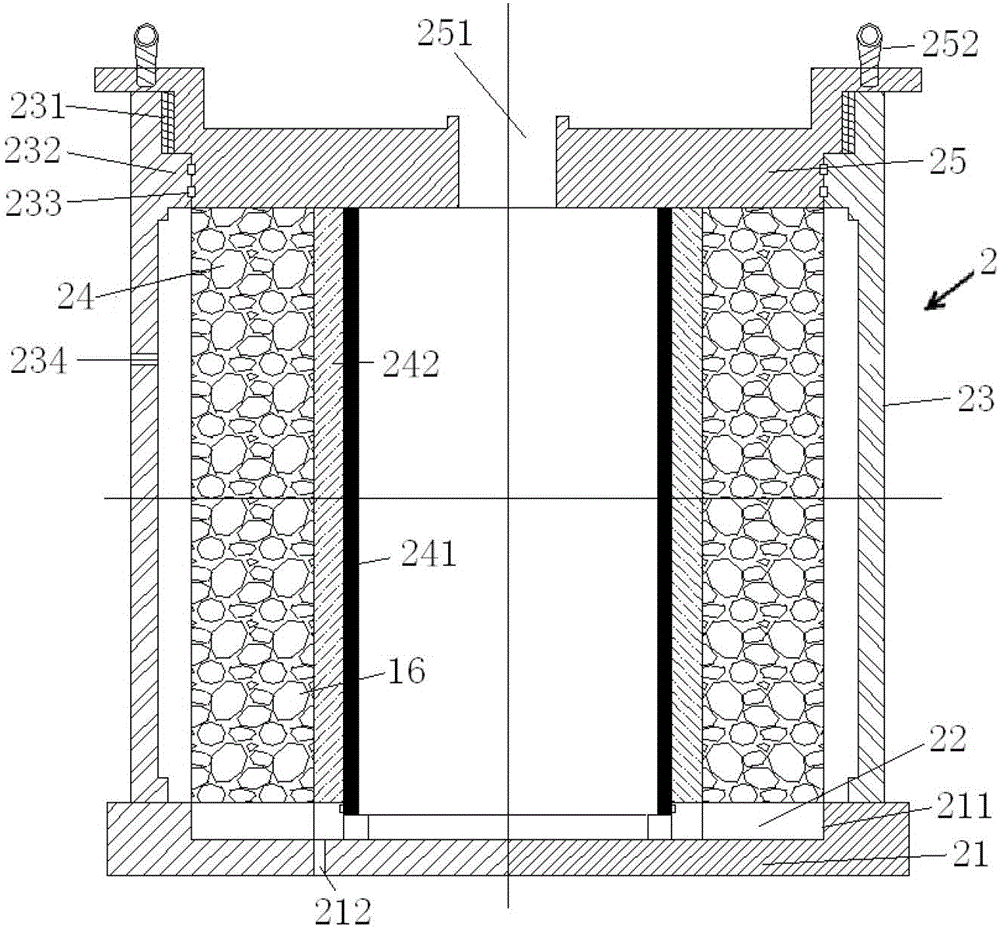

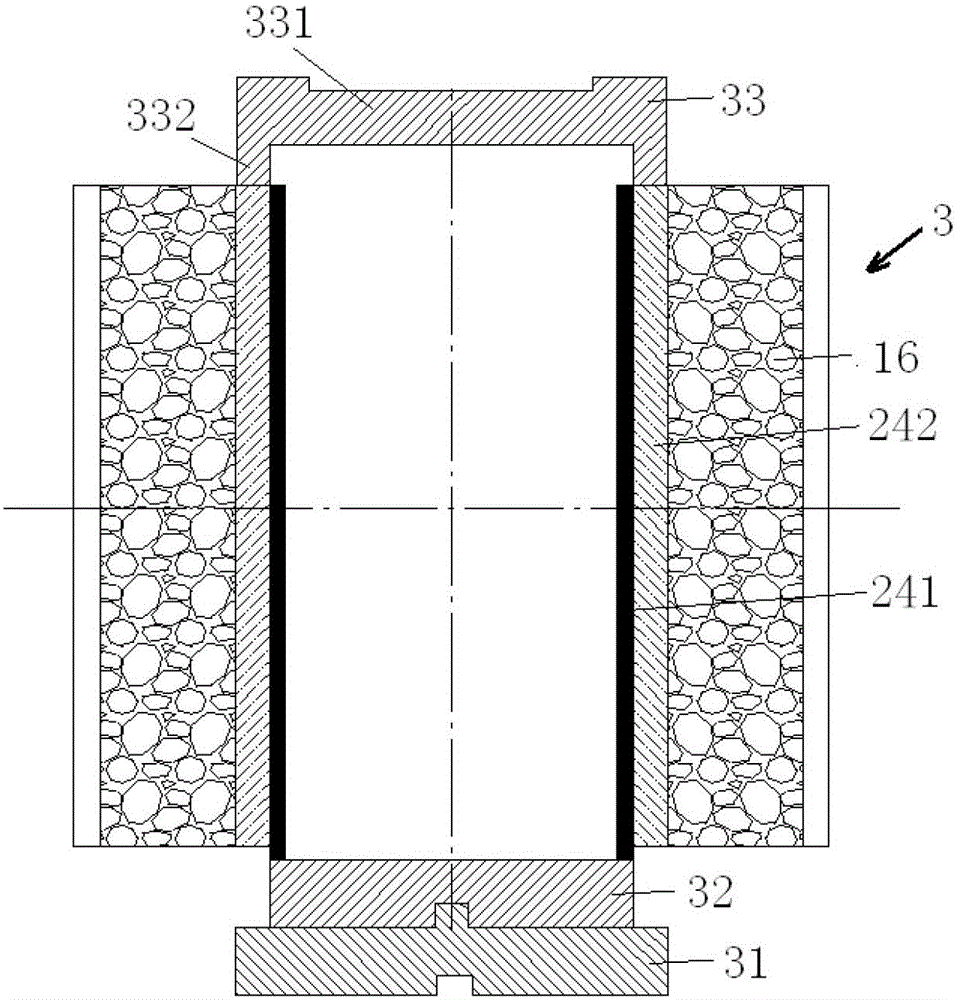

[0034] Such as figure 1 , figure 2 , image 3 As shown, the device of the present invention includes a mud cake circulation device 1 , a cement sheath performance detection device 2 and a cemented surface shear force test device 3 .

[0035] Such as figure 1 , Figure 4 As shown, the mud cake circulation device 1 includes a lower kettle cover 11, a lower bracket 12, a cylinder body 13, an upper bracket 14, an upper kettle cover 15, and a formation sample 16. According to the requirements of the experiment, a drill pipe is also arranged in the cylinder body 3. 7 or experimental tools such as well washing pipe 8. A circle of concave edges 111 and 112 are arranged at the center of the top surface and the bottom surface of the lower kettle cover 11 respectively, and a liquid opening 113 is vertically arranged on the top surface concave edge 112 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com