Method of sealing wells by squeezing sealant

a well sealing and sealant technology, applied in the direction of sealing/packing, earthwork drilling and mining, borehole/well accessories, etc., can solve the problems of inability to use conventional portland cement for squeeze cementing, and inability to squeeze cemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

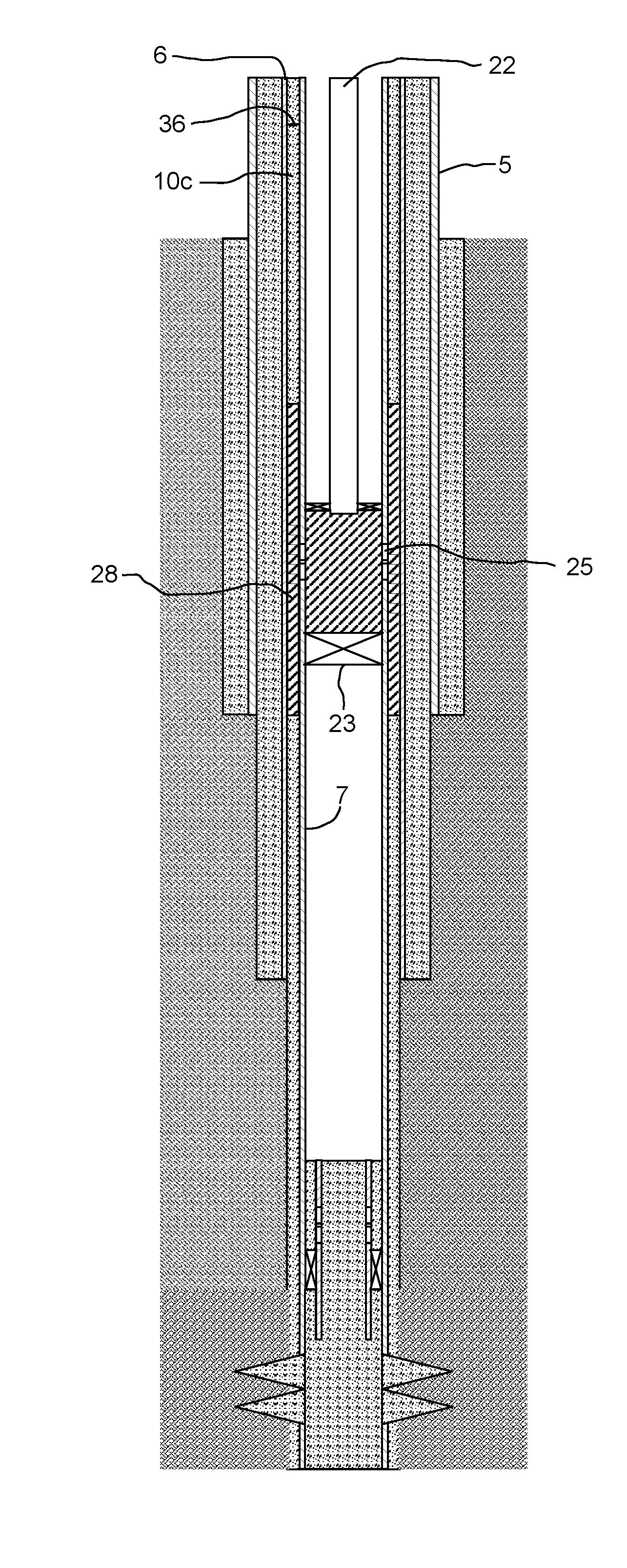

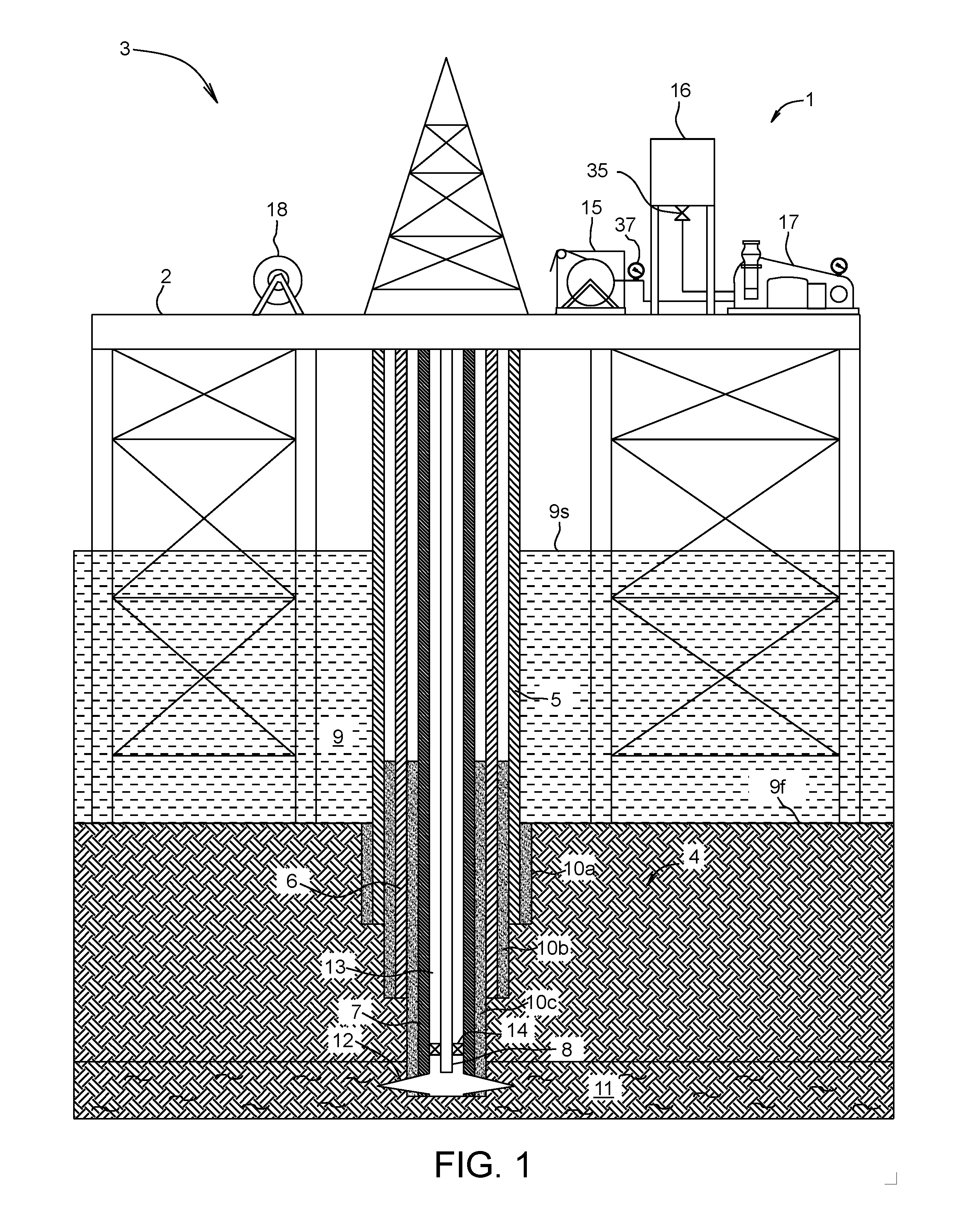

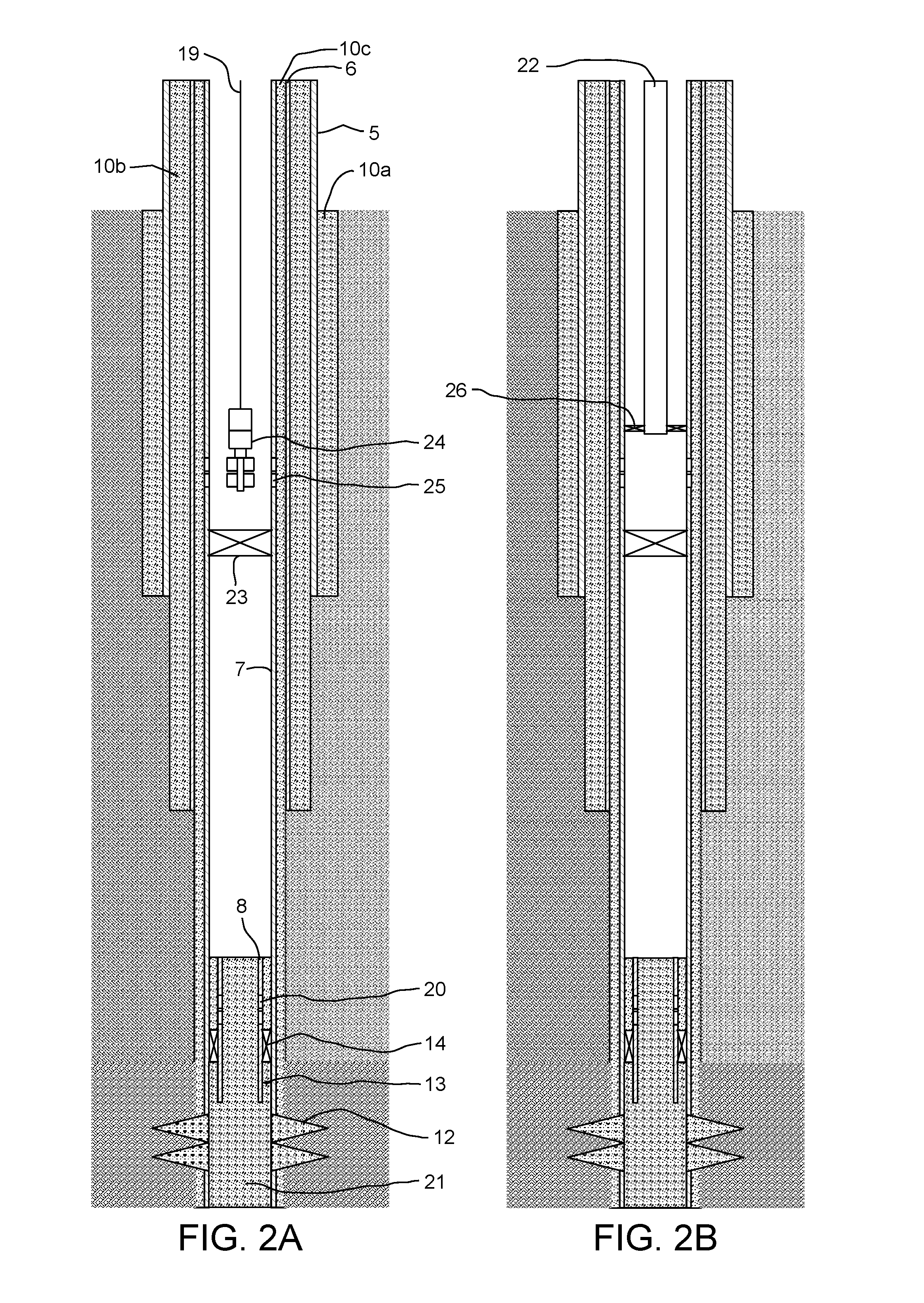

[0016]FIG. 1 illustrates an illustrative equipment package 1 used for performing the squeeze operation, and located on a platform 2, according to one embodiment of the present disclosure. The platform 2 may be part of a well 3 further including a subsea wellbore 4, a drive pipe 5, a surface casing string 6, a production casing string 7, and a production tubing string 8. The drive pipe 5 is commonly set from above a surface 9s (aka waterline) of the sea 9, through the sea, and into the seafloor 9f (aka mudline). The drive pipe 5 allows the wellhead (not shown) to be located on the platform 2 above the waterline 9s.

[0017]Once the drive pipe 5 has been set, and (if desired cemented 10a, the subsea wellbore 4 is drilled into the seafloor 9f within the envelope of the drive pipe 5. The surface casing string 6 is then run-in the drive pipe 5 and into the wellbore 4 and cemented into place by forming a cement sheath 10b. When the wellbore 4 reaches a hydrocarbon-bearing formation 11, i.e....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com