Oil/gas well cement sheath sealing integrity testing device and method for carrying out evaluation through device

A testing device and cement ring technology, applied in construction and other directions, can solve the problems of not being able to meet the comprehensive measurement, the sealing performance is not good enough, etc., and achieve the effect of monitoring and size measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The invention will be further described below in conjunction with specific embodiments.

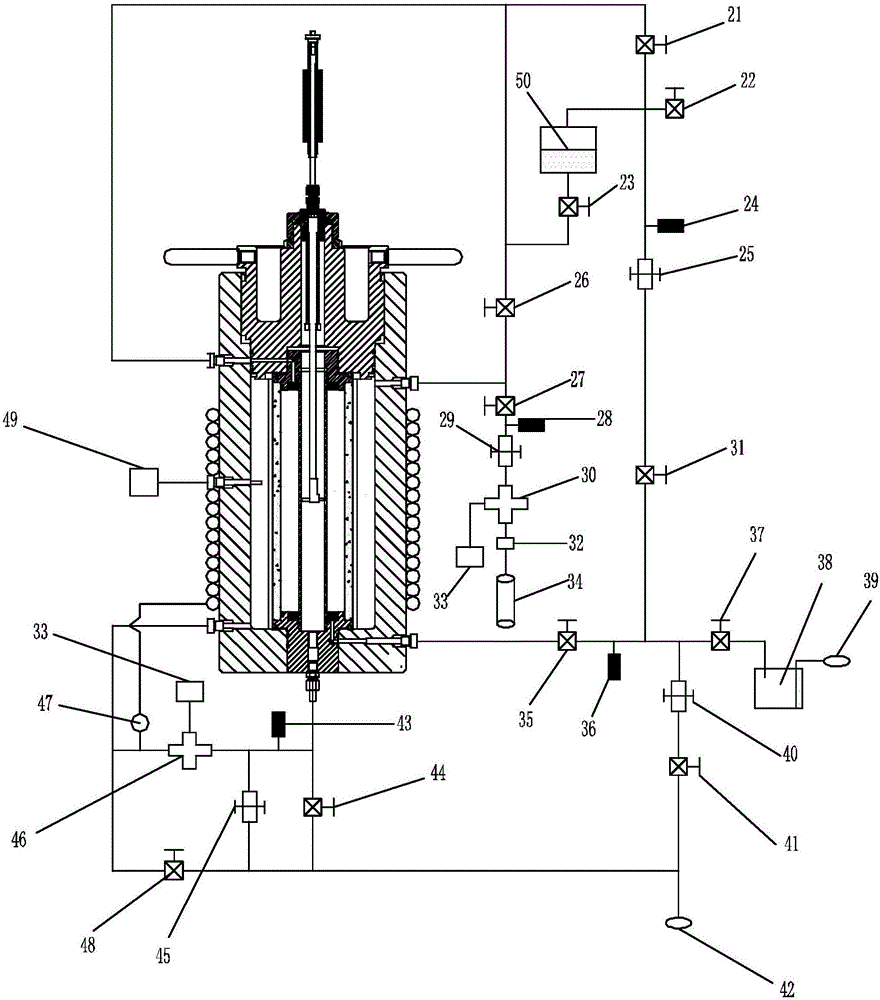

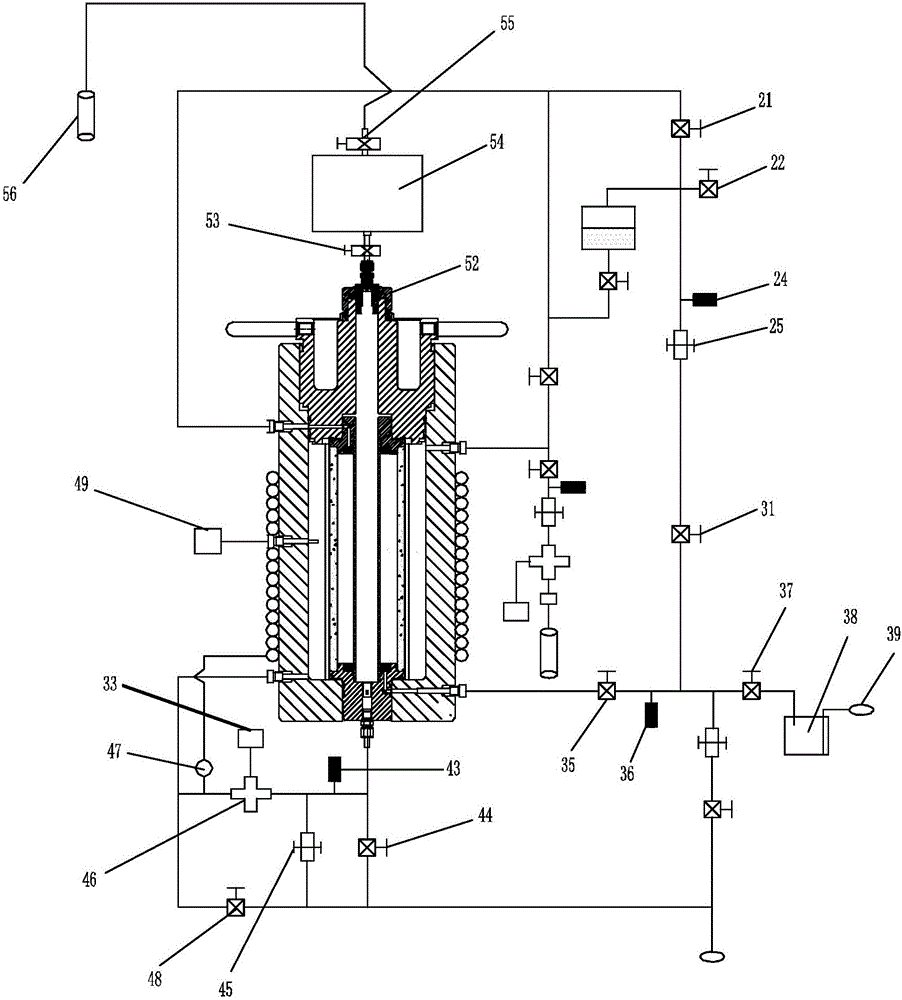

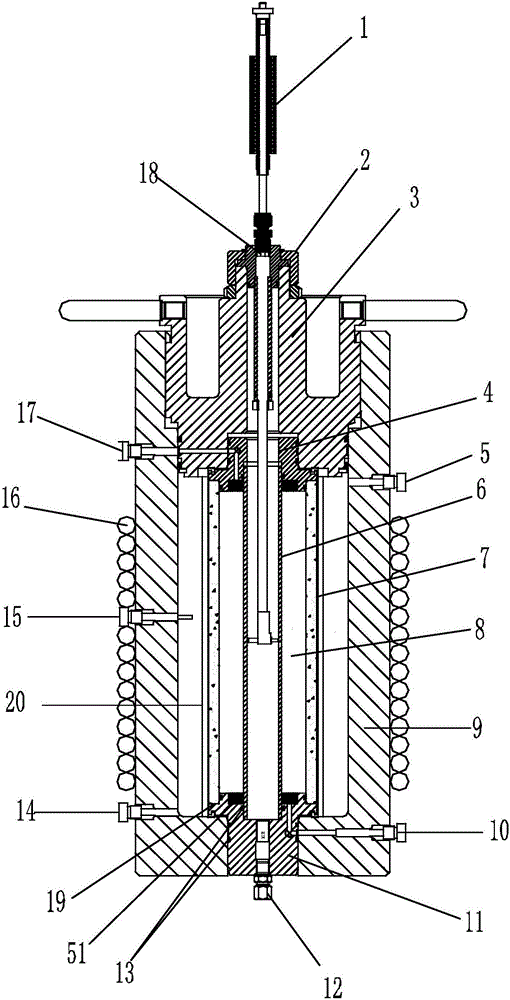

[0061] Such as Figure 1-3 A device for testing the seal integrity of an oil and gas well cement ring is shown, including a pressure vessel and a simulated wellbore located inside the pressure vessel, and the test device also includes a pressure control system, a temperature control system, a channeling detection system, and a strain measurement system And mud cake simulation system; among them, the simulated wellbore includes casing 6 and core 7 located outside casing 6, an annular gap is formed between casing 6 and core 7, and cement ring 8 is formed in the annular gap; casing 6 and core 7 The upper and lower ends are respectively provided with an upper end cover 4 and a lower end cover 11; the pressure kettle includes a kettle body 9 and a kettle cover 3 matched with the kettle body 9; the kettle body 9 is provided with a cement ring pressure port 17 together with the top of the cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com