Wellbore cleaning tool system and method of use

a wellbore and tool system technology, applied in the direction of wellbore/well accessories, fluid removal, earthwork drilling and mining, etc., can solve the problems of increasing the cost of operations, reducing the efficiency of scrapping and brushing, and accumulation of round trip delays to journal the cleaning devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

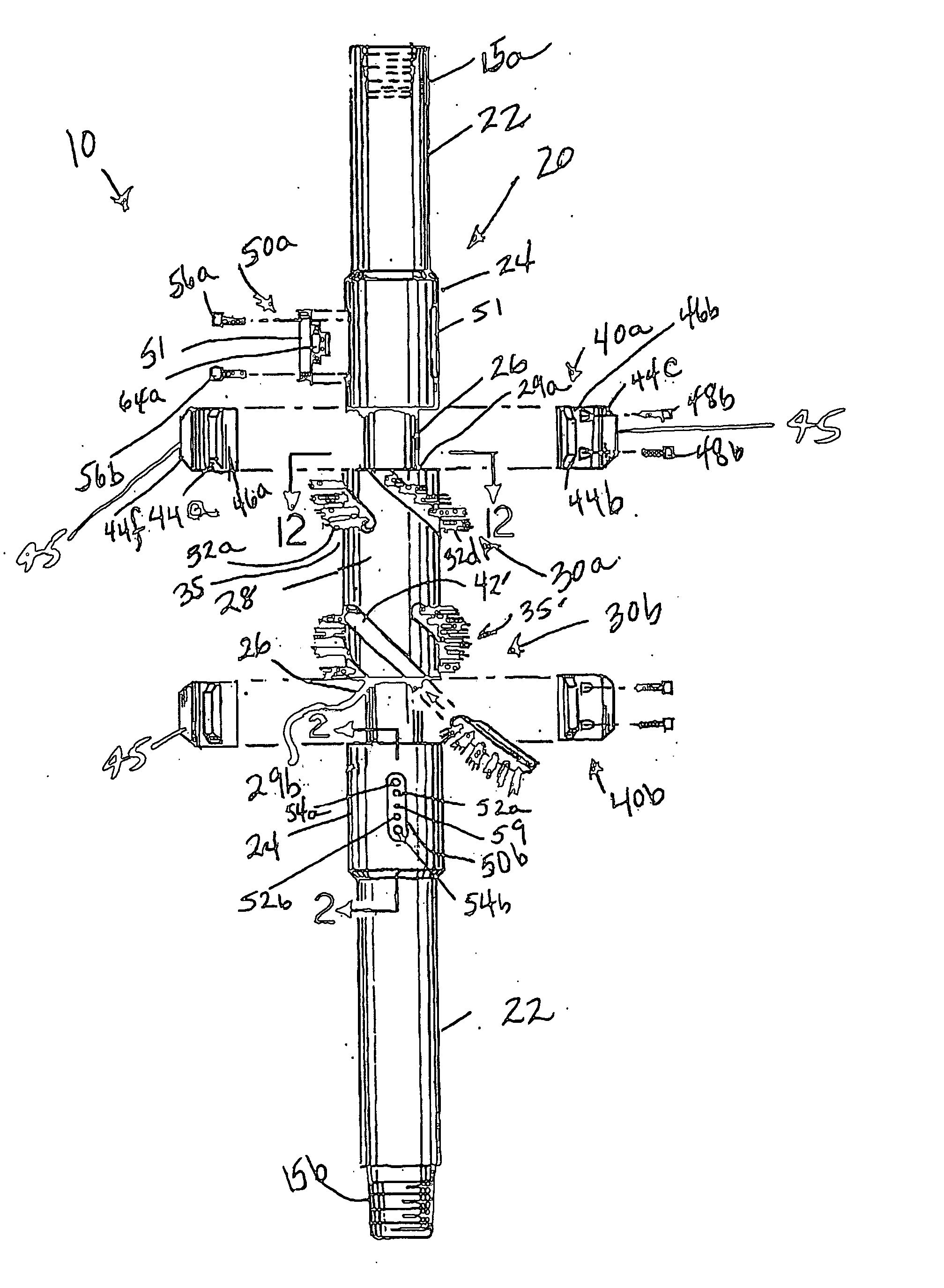

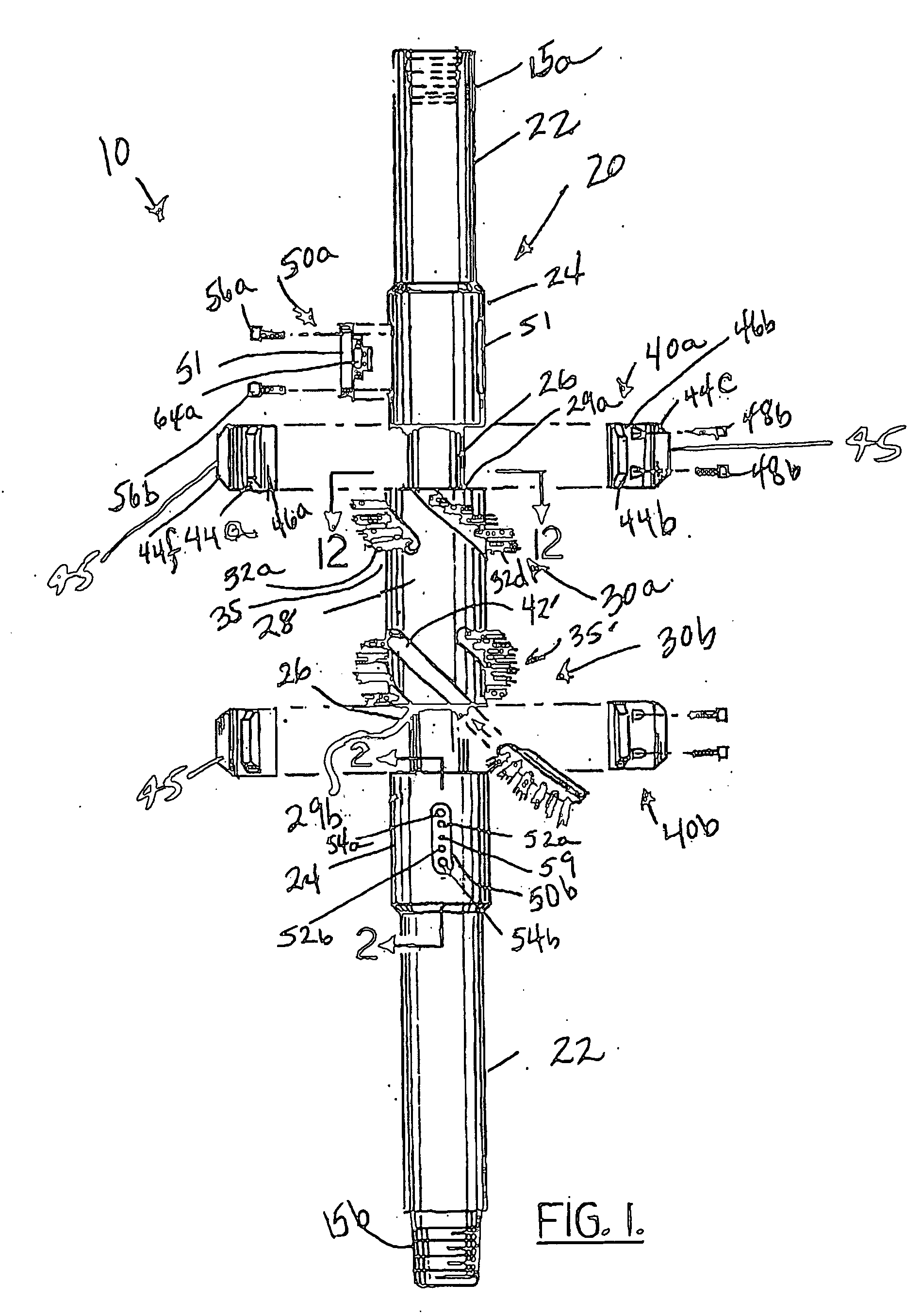

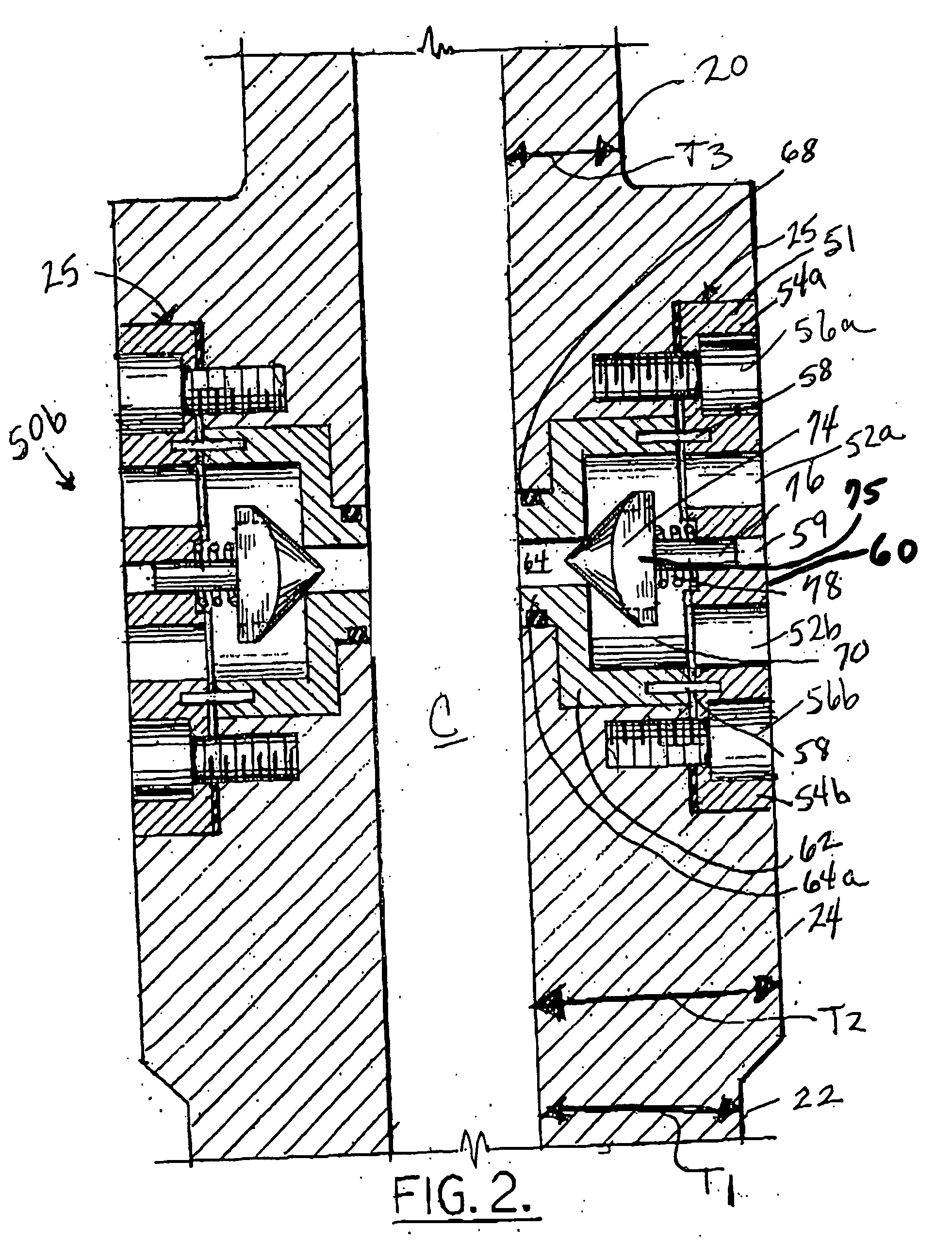

[0069] Referring now to the drawings and in particular FIGS. 1 and 14, the wellbore cleaning tool apparatus of the present invention will generally be referenced by the numeral 10 with the wellbore cleaning tool system being referenced by the numeral 100. The wellbore cleaning tool apparatus 10 includes, in general, a casing body 20 adapted to be centralized in the wellbore 5 (FIG. 24) via top and bottom stabilizers (NOT SHOWN), a plurality of sets of brushes 30a and 30b, a plurality of sets of scrapers 40a and 40b and a plurality of sets of jet spray assemblies 50a and 50b for high-velocity jet spraying of the interior wall of the wellbore 5 for an added cleanout effect. As will be seen from the description provided below, the high-velocity jet sprays also aid in cleaning the plurality of sets of brushes 30a and 30b and the plurality of sets of scrapers 40a and 40b during cleaning operations so that any build-up of the mud cake, cement sheath, etc., when being brushed or scraped fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com