Layered hydraulic fracturing method of underground coal mine multiple coal seams

A hydraulic fracturing, multi-coal seam technology, applied in mining equipment, earthmoving, wellbore/well components, etc., can solve problems such as low cost, and achieve the effect of low cost, high success rate and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

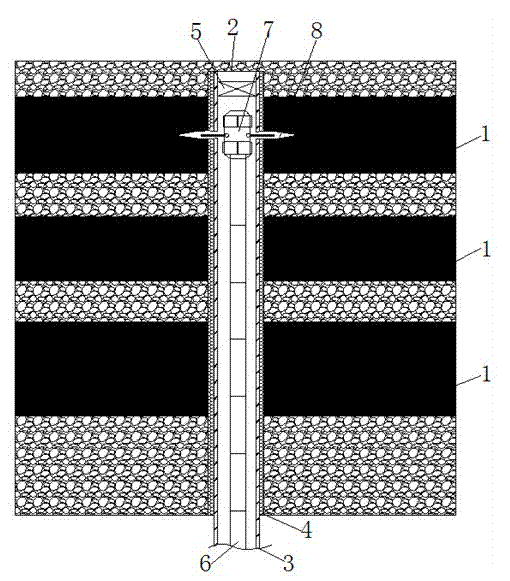

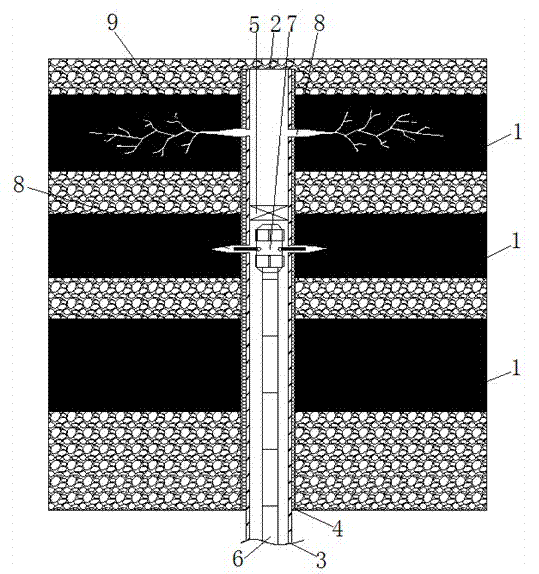

[0021] figure 1 It is a layered hydraulic fracturing method for multi-coal seams in a coal mine of the present invention, and it is a schematic diagram of perforating the first coal seam; the specific operation steps are as follows:

[0022] (1) Drill a drill hole 2 through all coal seams 1 from the side of the road to the coal seam group;

[0023] (2) Install the coal seam hydraulic fracturing casing 3 in the through-bed borehole, and then use cement slurry to cement the hole to the bottom of the through-bed drilled hole 2;

[0024] (3) Use the sealing device 5 to seal the hole to the roof of the coal seam to be fractured, connect the high-pressure sealing drill pipe 6 to the perforating gun 7, and send the perforating gun 7 to the The coal seam to be fractured in the drill hole 2;

[0025] (4) Calibrate the position of the perforating gun 7 so that it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com