Apparatus and method for testing cementation capability of well cementation first and second interfaces under high-temperature high-pressure conditions

A high-temperature, high-pressure, ability-testing technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems that cannot be truly simulated, inconsistent, and rarely consider the quantitative evaluation of sealing ability, so as to achieve reliable experimental principles and evaluation Accurate, simple and convenient experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

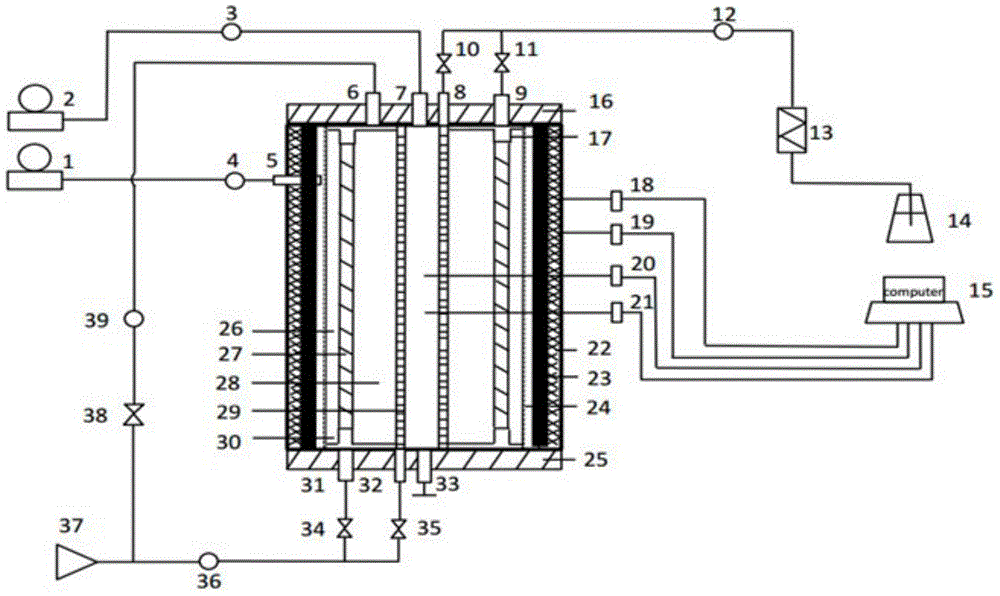

[0027] Further illustrate the present invention below in conjunction with accompanying drawing.

[0028] see figure 1 .

[0029] High-temperature and high-pressure well cementing first and second interface sealability test device, mainly composed of kettle body 23, external pressure pump 1, internal pressure pump 2, heating belt 22, confining pressure sleeve 24, internal pressure pipe 29, convex ring plug 30 , concave ring plug 17, nitrogen source 37, rotameter 13, observation conical flask 14, external pressure sensor 18, external couple 19, internal pressure sensor 20, internal couple 21, gas-liquid discharge valve 33, computer 15 .

[0030]Inside the kettle body 23, there are sequentially placed a confining pressure sleeve 24, a simulated rock core 26, an artificial mud cake 27, a cement sheath 28, and an internal pressure pipe 29 from the outside to the inside. 21. The outside of the kettle body 23 is connected to the external pressure pump 1 through the confining press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com