Apparatus and test method for testing three-dimensional stress state inside concrete

A technology of three-dimensional stress and testing methods, which is applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problems of lack of Internet of Things systems, high cost of concrete structure testing, lack of systematic data, etc., and achieve the effect of improving safety reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

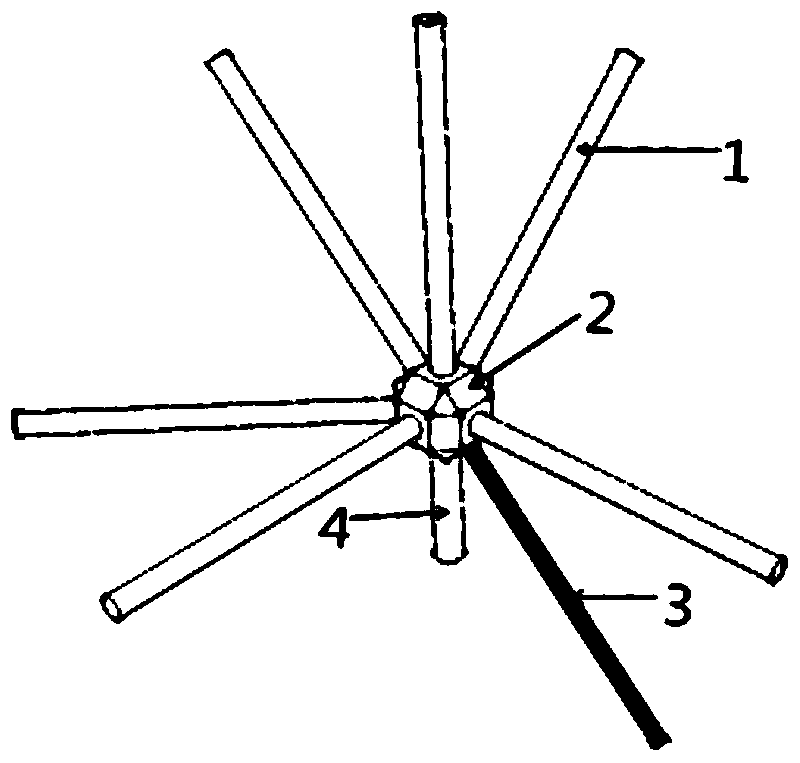

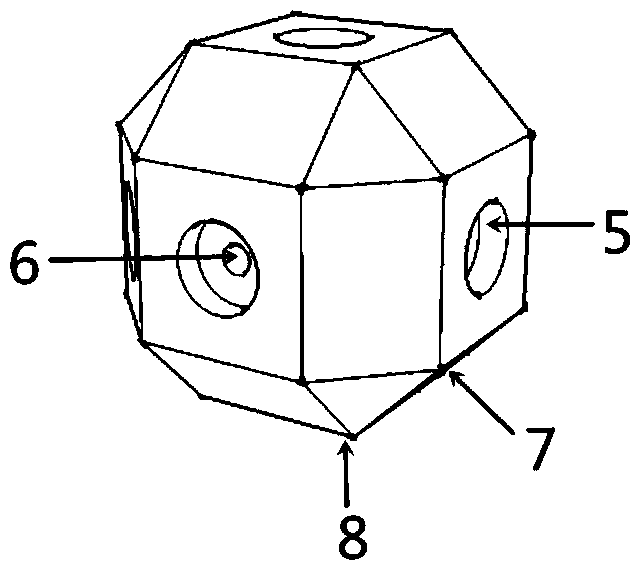

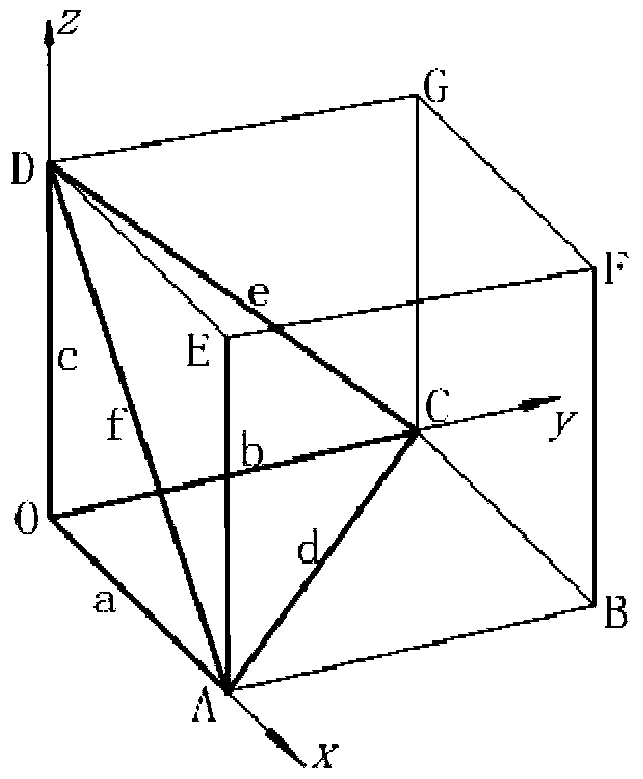

[0018] The device for testing the three-dimensional stress state inside concrete and the testing method thereof of the present invention are described in conjunction with the accompanying drawings.

[0019] The device for testing the three-dimensional stress state in concrete and the testing method thereof of the present invention are based on: the stress state of a point in space is expressed by three normal stresses and three shear stresses totaling six stress components, so at least six mutually independent The test element to determine the state of stress at a point in space. The invention performs equivalent transformation on several edges of the regular tetrahedron to meet the operating principle and environmental requirements of the one-way stress meter, thereby being used for the stress test inside the concrete.

[0020] The structure of the device for testing the three-dimensional stress state inside the concrete of the present invention is that the three-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com