True stress-true strain computation model and test system

A technique for calculating model, true strain, applied in the field of experimental mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

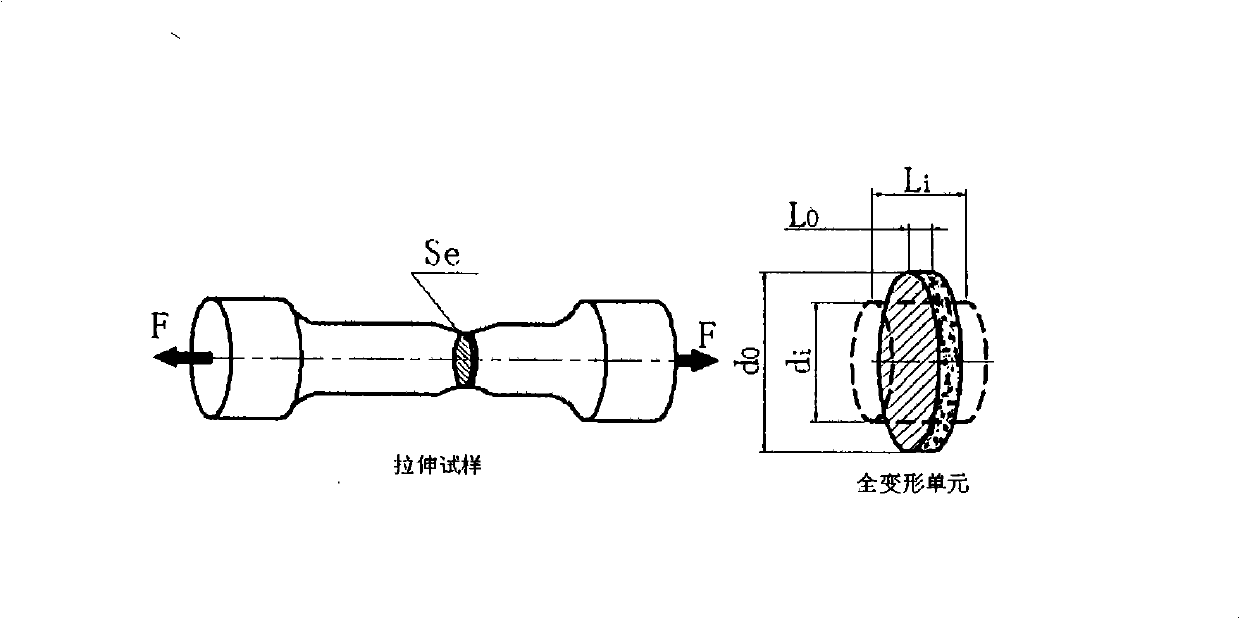

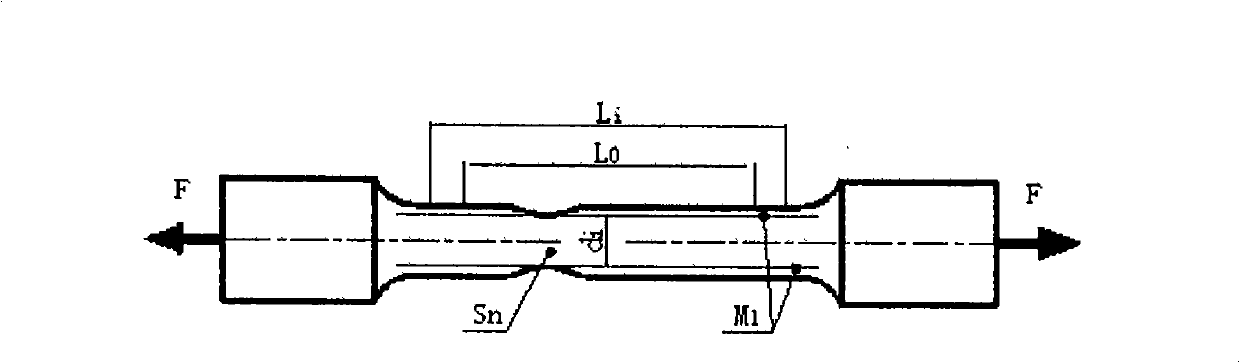

[0033] The basic idea of the total denaturation unit analysis method of the present invention is that when the sample is stretched, only the micro unit at the minimum diameter of the final fracture has experienced each stage of the whole deformation process until fracture, so only the mechanical properties of this micro unit The behavior can truly and completely reflect the real constitutive relationship of the material. Therefore, only the stress and strain measured on this unit are the real stress and strain. From the geometrical characteristics of deformation, when the material is necked, the material near the minimum diameter is basically a geometrically symmetrical body, where the length is l 0 As the analysis unit with a tiny length of , in the limit case where the length tends to zero, the change of the curvature of the busbar can be ignored, and it can be regarded as a pie-shaped unit body, then its model and deformation characteristics are as follows figure 1 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com