Automatic assembly machine for lipstick packaging pipes

A technology for automatic assembly machines and packaging tubes, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, high labor intensity, and high labor costs, and achieve low cost, small footprint, and high positioning high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The lipstick packaging tube automatic assembly machine of the present invention will be described in further detail below in conjunction with the accompanying drawings.

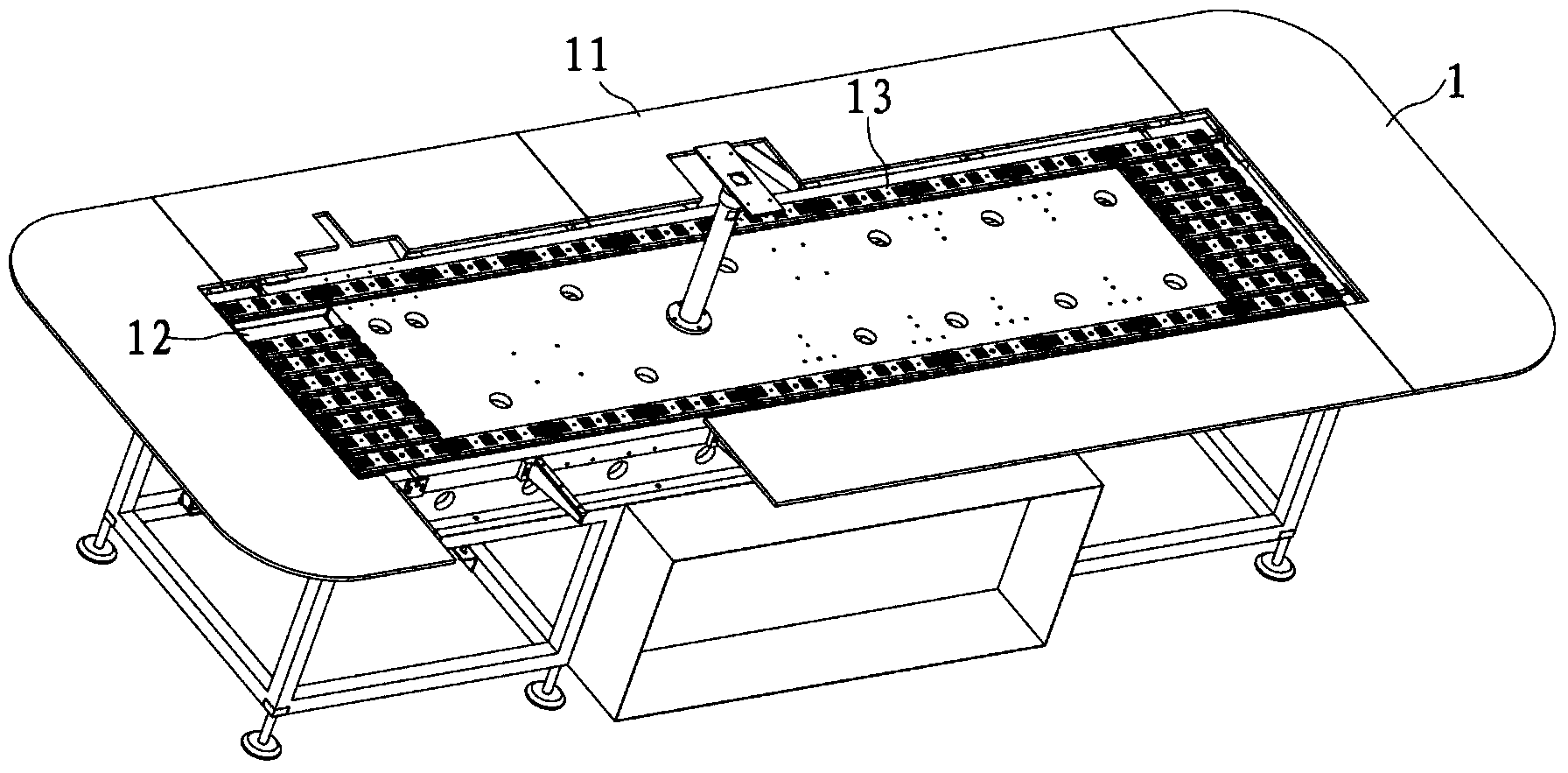

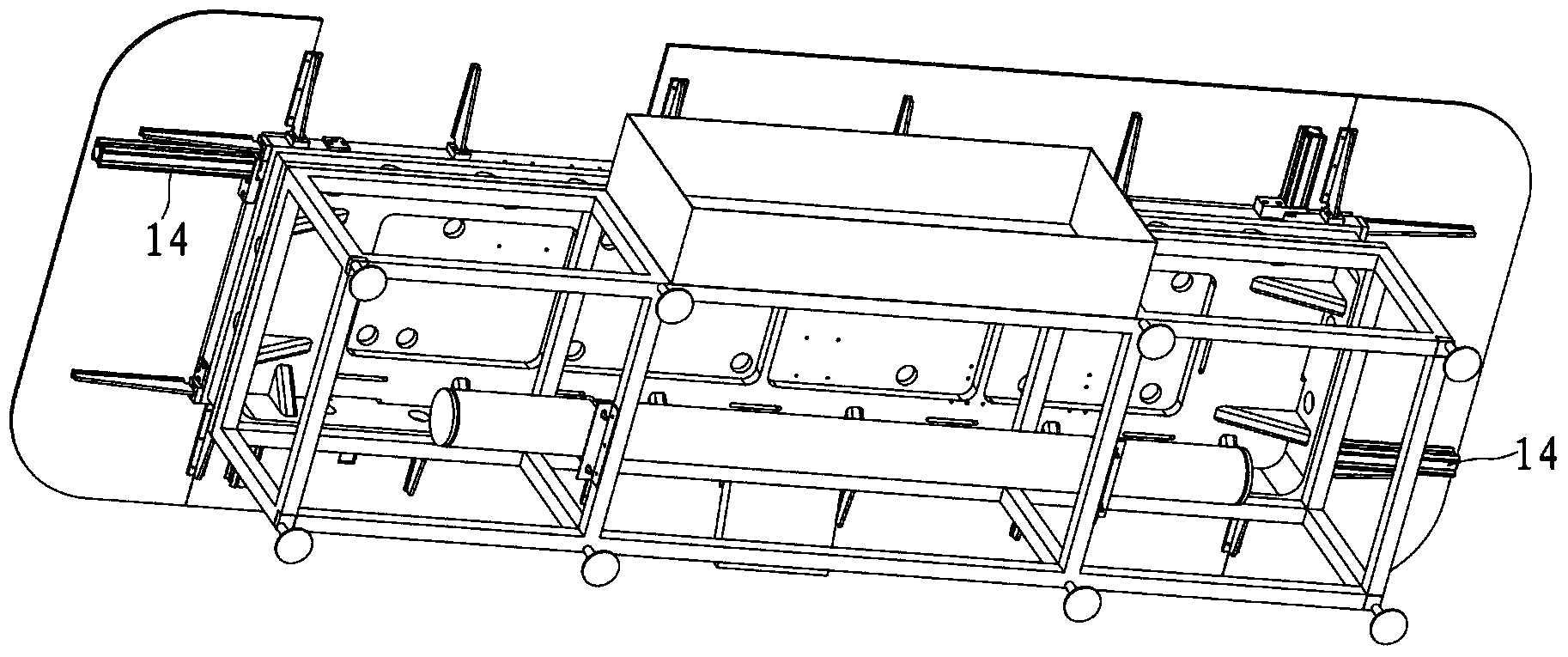

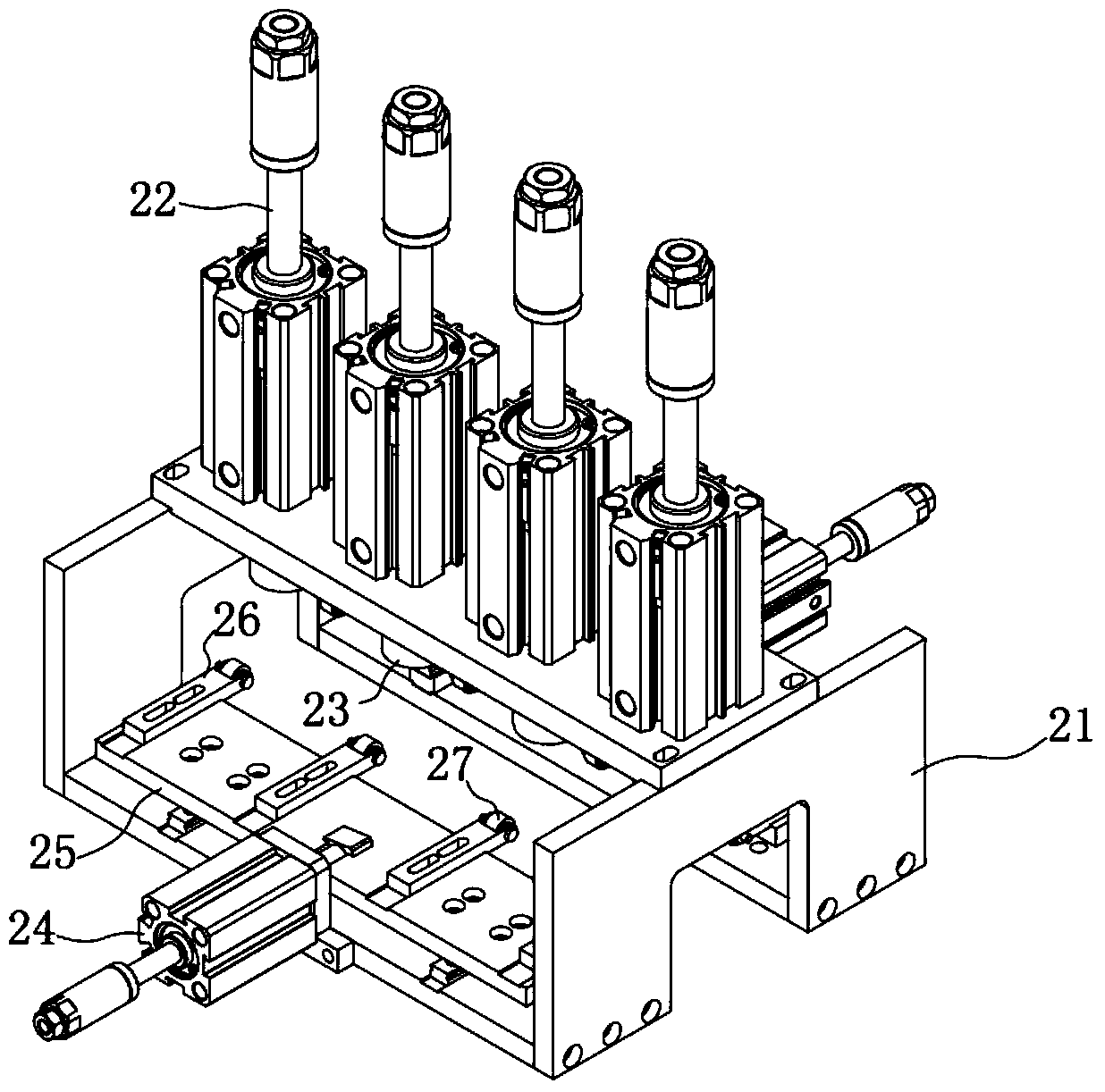

[0051] An automatic assembly machine for lipstick packaging tubes, comprising a main body frame 1, an annular guide rail groove 12 is arranged on a workbench 11 at the top of the main body frame 1, and a jig plate 13 for placing lipstick packaging tubes is slidingly fitted in the guide rail groove 12 ; On the workbench, around the guide rail groove 12, it is successively divided into a side piece press-fitting work area, a pad iron installation work area, a glue-touching work area, a center beam core press-fitting work area and a blanking work area.

[0052] The structure of the main frame 1 is as figure 1 and figure 2 As shown, the annular guide rail groove 12 is located on the top surface workbench 11 of the main body frame 1, inside the guide rail groove 12 there is a fixture plate 13 for placing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com