Full-automatic wafer splitting equipment based on visual pre-correction positioning

A fully automatic, wafer-based technology, applied in stone processing equipment, fine working devices, working accessories, etc., can solve the problems of substandard wafer splitting size and deviation in processing positioning accuracy, and improve splitting positioning accuracy , Guarantee the effect of processing and the quality of processed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015]下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。

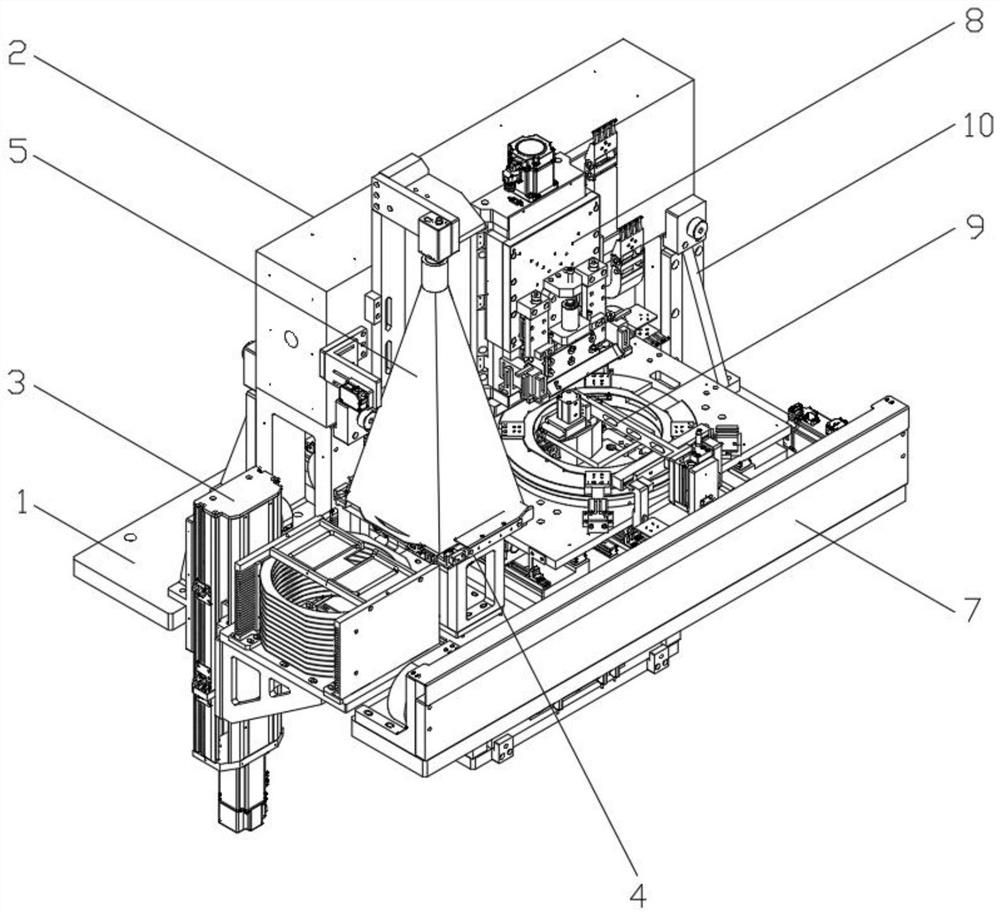

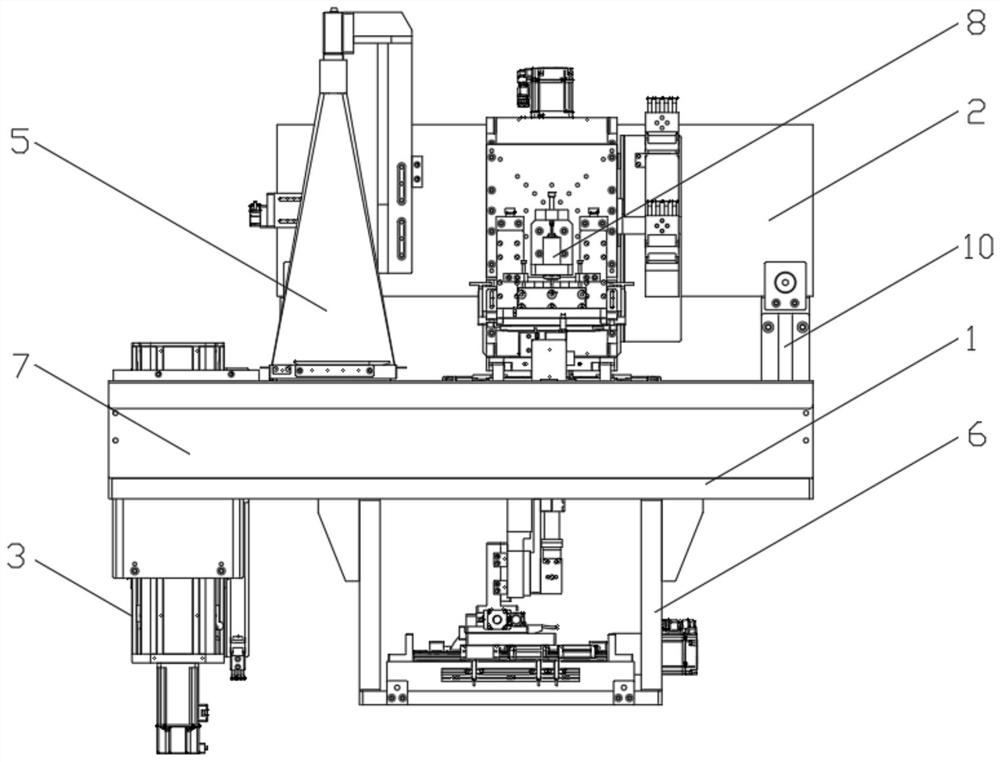

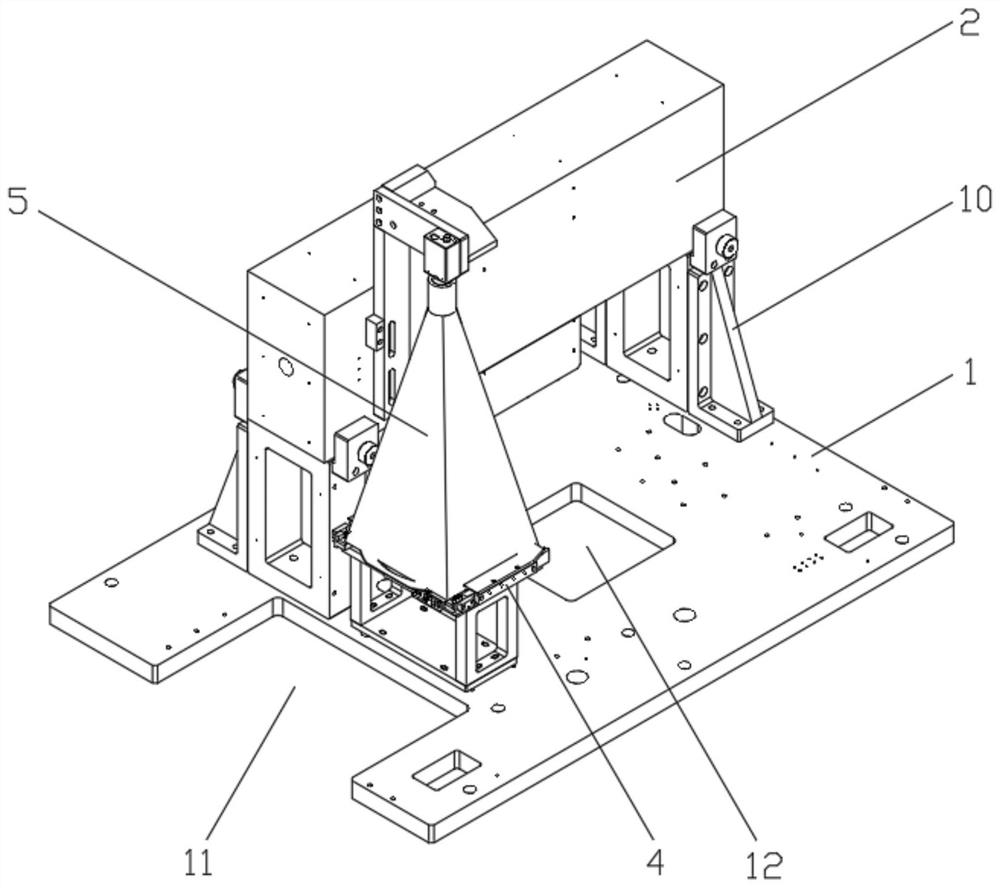

[0016]请参阅图1-3,本发明提供一种技术方案:基于视觉预校定位的全自动晶圆劈裂设备,包括机架大板1、横梁2、料仓组件3、预校台组件4、上相机组件5、下相机组件6、搬运机械手组件7、劈刀组件8、劈裂平台9,所述机架大板1的上表面一侧对称设有座体10,所述横梁2固定安装在两座体10上,所述机架大板1的一端壁设有开槽11,所述料仓组件3固定安装在开槽11的内侧壁上,所述料仓组件3用于存放多个晶圆且带动晶圆做升降运动,所述上相机组件5固定安装在横梁2的侧壁且靠近料仓组件3的位置,所述预校台组件4固定安装在机架大板1的上表面且位于上相机组件5的下部,所述预校台组件4用于将晶圆调节到上相机组件5的正下方,所述上相机组件5拍摄晶圆且判断晶圆的完整度,利用预校台组件4的自适应调节,将晶圆产品移动到中心位置,并用上相机组件5拍摄加工材料的形状并判断加工材料是整片还是残片,保证加工件质量,所述劈刀组件8固定安装在横梁2的侧壁且靠近上相机组件5的位置,所述劈裂平台9固定安装在机架大板1的上表面且位于劈刀组件8的下部,所述劈裂平台9用于对晶圆实现移动精准定位,所述机架大板1的表面且位于劈裂平台9的下部设有开口12,所述下相机组件6固定安装在机架大板1的下表面位置,所述下相机组件6通过开口12拍摄晶圆且判断晶圆的完整度,同时确定晶圆的加工位置,晶圆通过搬运机械手组件7抓取到劈裂平台9上,卡紧晶圆产品,下相机组件6移动到拍照位置,在此位置上,通过机架大板1上的开口12,配合劈刀组件8及劈裂平台9上直线光源,下相机组件6可以拍摄到晶圆的情况,进而判断晶圆产品的好坏及确定加工位置,所述搬运机械手组件7固定安装在机架大板1的一边缘壁上,所述搬运机械手组件7用于将晶圆从料仓组件3上夹取然后依次放置到预校台组件4上和劈裂平台9上。

[0017]具体而言,所述横梁2采用大理石材质,用于减小劈裂过程中的机械振动。

[0018]具体而言,所述下相机组件6为移动式下相机组件6。

[0019]具体而言,所述预校台组件4位于料仓组件3与劈裂平...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com