Using method for box finish-milling locating tool

A technology for positioning tooling and cabinets, which is applied in the field of tooling and fixtures, can solve problems such as unsuitable precision requirements, large structural size, and complex structure, and achieve the effects of high positioning processing accuracy, easy operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

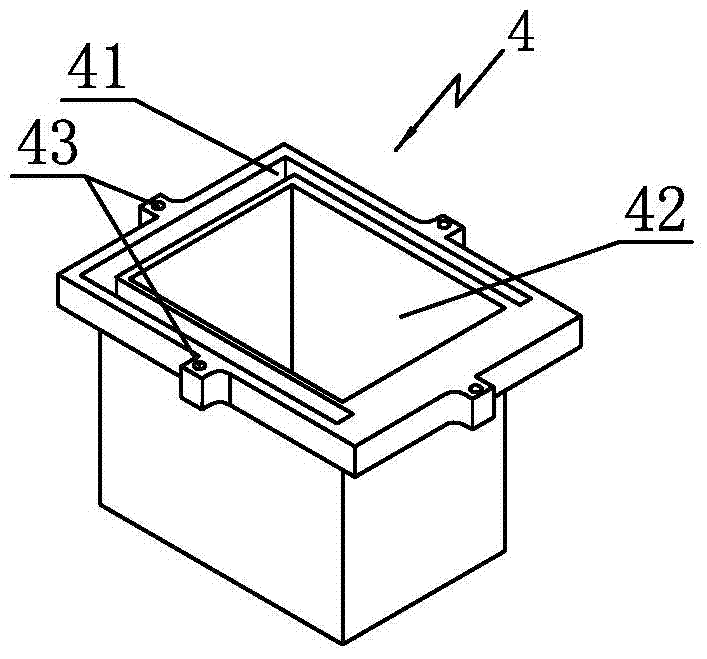

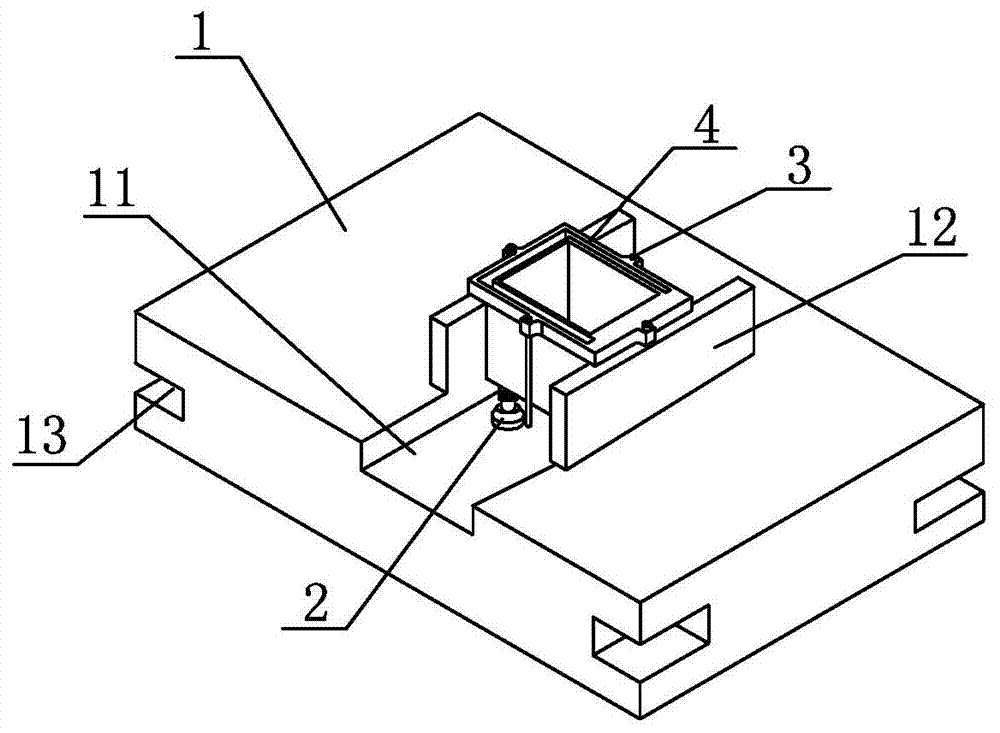

[0016] like figure 1 and figure 2 As shown, the present invention includes a positioning seat 1 and a positioning pin 3; the positioning seat 1 has a square groove 11, and the width of the groove 11 is greater than the width of the box body 4; the top surface of the positioning seat 1 is located at the side wall of the groove 11 Positioning plate 12 is arranged symmetrically on the edge, and the top surface of positioning plate 12 all has positioning hole, and casing 4 can be positioned and fixed on two positioning plates 12 by the positioning hole 43 on the described positioning hole and casing 4; Two adjustment devices 2 are placed on the bottom surface of the groove 11. The adjustment device 2 is located below the outer bottom surface of the box body 4. The bolts on the rotation adjustment device 2 can be tightened from the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com