Non-standard clamp device for clamp body and inlay machining device

A standard clip and pliers technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as low processing efficiency and poor product quality, and achieve improved production efficiency, improved accuracy errors, and improved positioning. The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

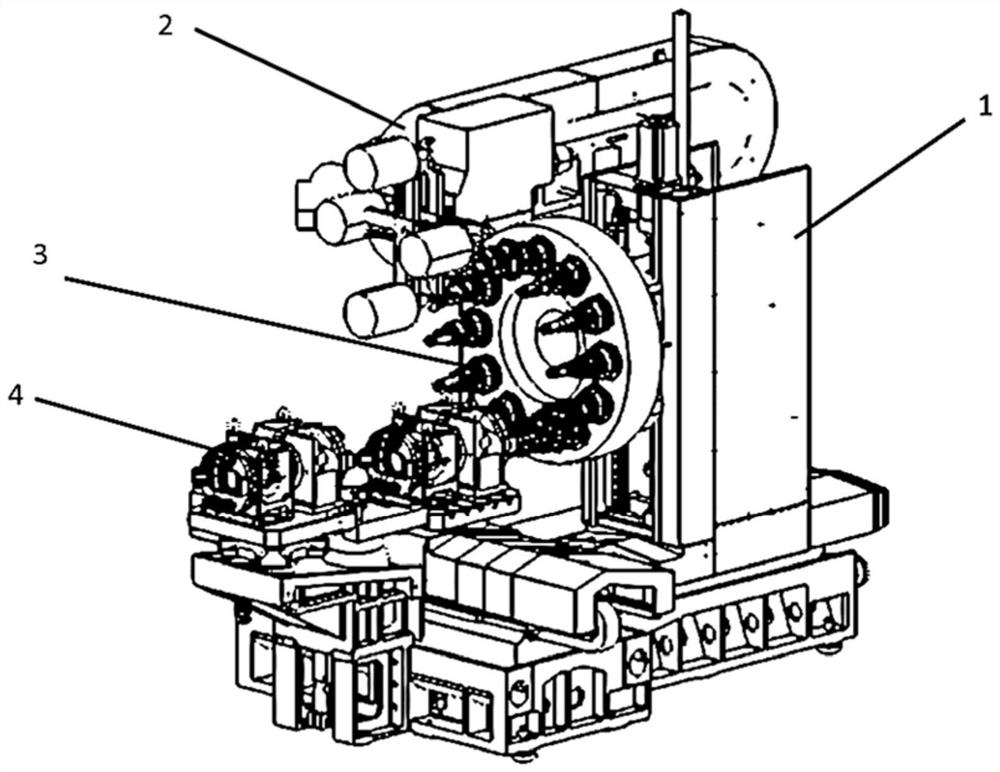

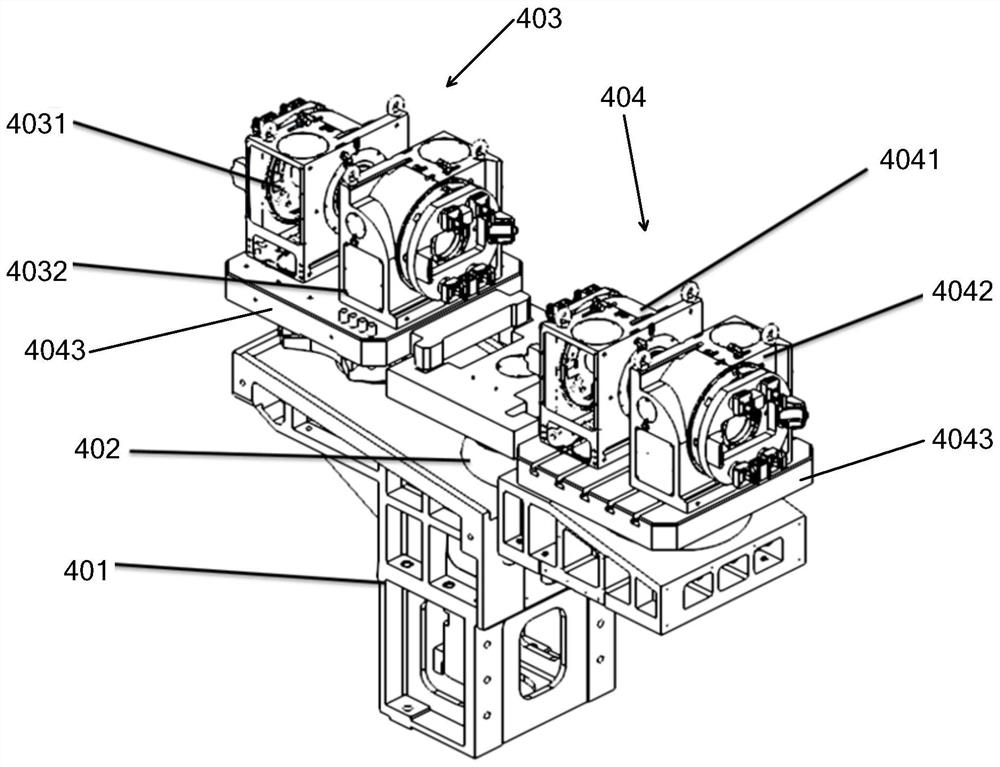

[0052] Such as Figure 1~3 As shown, a non-standard fixture device for pliers provided in this embodiment includes a fuselage body 1, a chain tool magazine 2, a headstock 3 and a hydraulic fixture assembly 4, a chain tool magazine 2, a headstock 3 and a hydraulic fixture Components 4 are all arranged on the main body 1 of the fuselage. The hydraulic clamp component 4 includes a base 401, a rotary table 402, a first hydraulic clamp component 403 and a second hydraulic clamp component 404. The base 401 is arranged on the main body 1 of the fuselage. The table 402 is rotatably arranged on the base 401 , and the first hydraulic clamp assembly 403 and the second hydraulic clamp assembly 404 are respectively provided at both ends of the rotary table 402 . The base 401 is installed on the fuselage main body 1 by means of screw locking. The rotary table 402 is coupled with the base 401 through a rotating shaft.

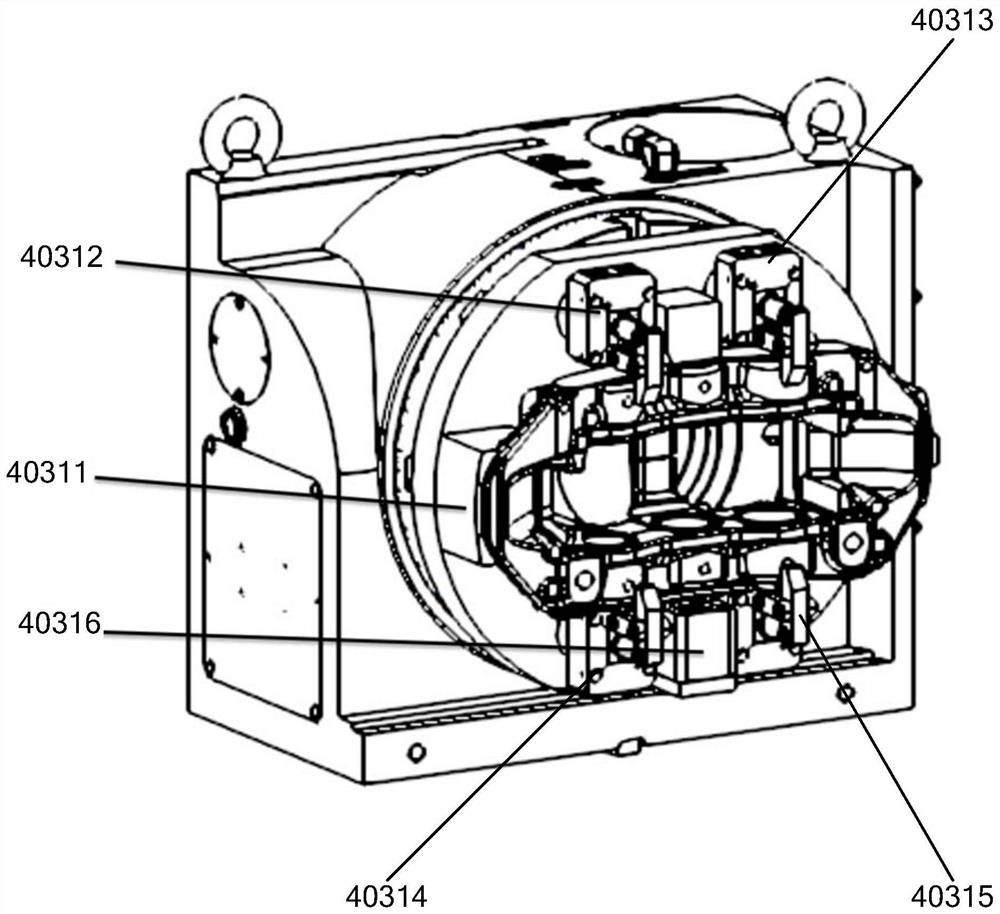

[0053]The first hydraulic fixture assembly 403 comprises a first hydra...

Embodiment 2

[0058] Those skilled in the art can understand this embodiment as a more specific description of Embodiment 1.

[0059] This embodiment provides a non-standard fixture device for pliers, which includes a fuselage body, a chain tool magazine, a spindle box, a hydraulic fixture set, a base, and a rotary table. The hydraulic fixture set includes hydraulic tooling A, hydraulic tooling B, and hydraulic tooling. C and hydraulic tooling D, hydraulic tooling A, hydraulic tooling B, hydraulic tooling C and hydraulic tooling D all include hydraulic lever cylinders, workbenches and cylinders.

[0060] Two oil pressure lever cylinders are distributed up and down on the workbench of the hydraulic tooling A, and air cylinders are installed inside the two oil pressure lever cylinders at the lower end. Hydraulic tooling B, hydraulic tooling C and hydraulic tooling D adopt the same structure as hydraulic tooling A, and hydraulic tooling A, hydraulic tooling B, hydraulic tooling C, and hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com