High-precision model locating device for five-axis numerical control machining

A positioning device and high-precision technology, applied in positioning devices, metal processing, large-scale fixed members, etc., can solve the problems of inaccurate processing accuracy, uneven workpiece quality, and unsuitable for large-scale processing. High positioning and machining accuracy, simple operation, and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

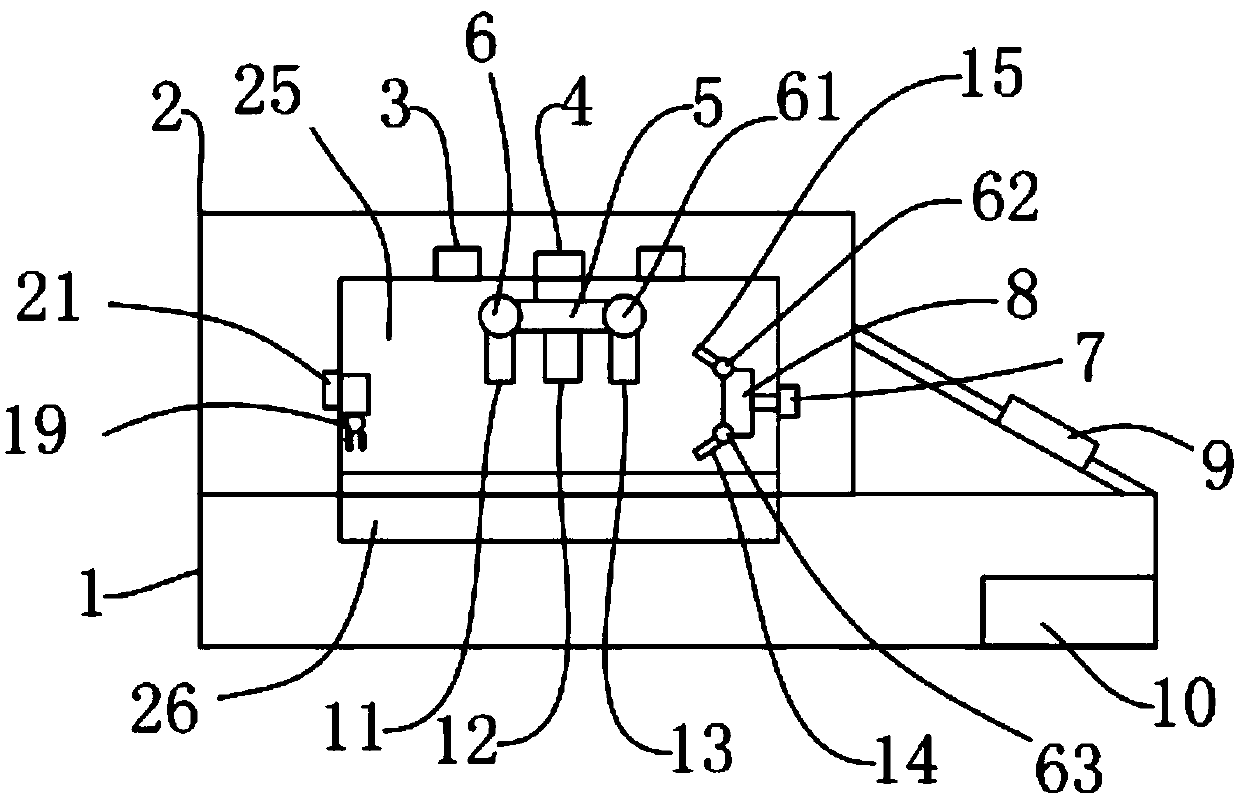

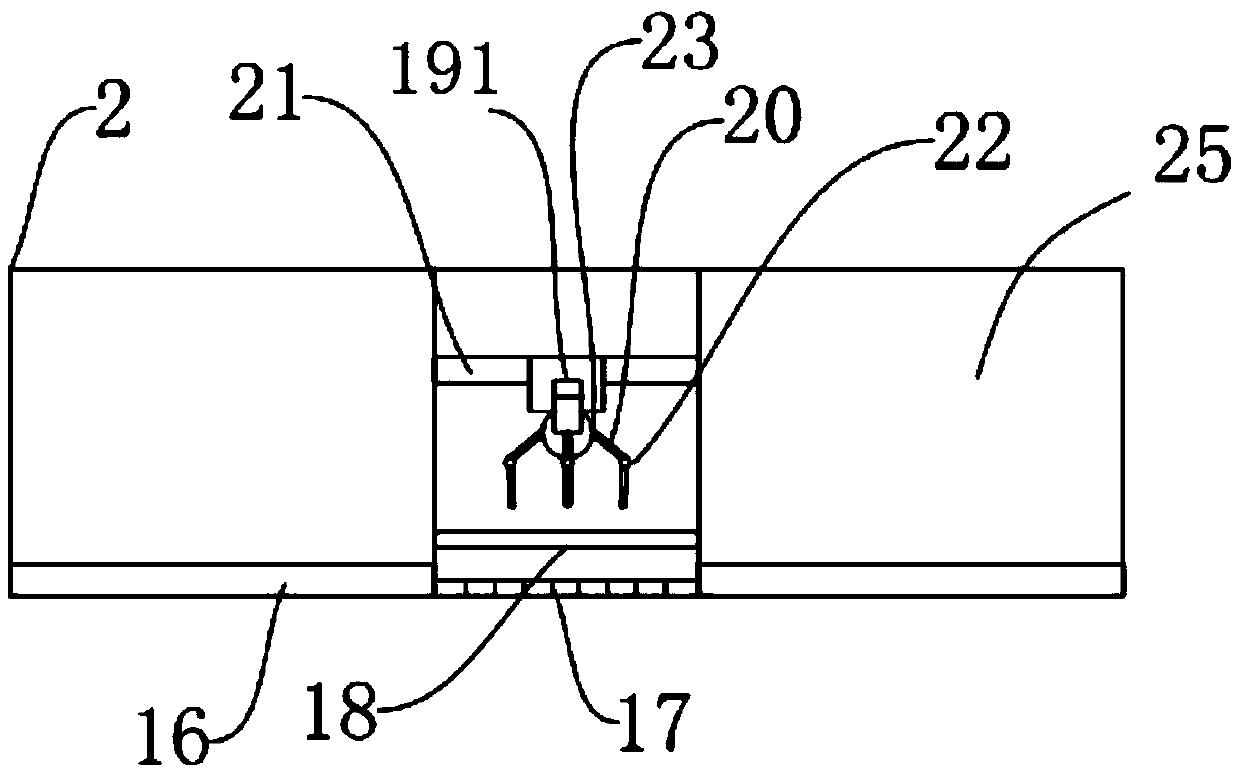

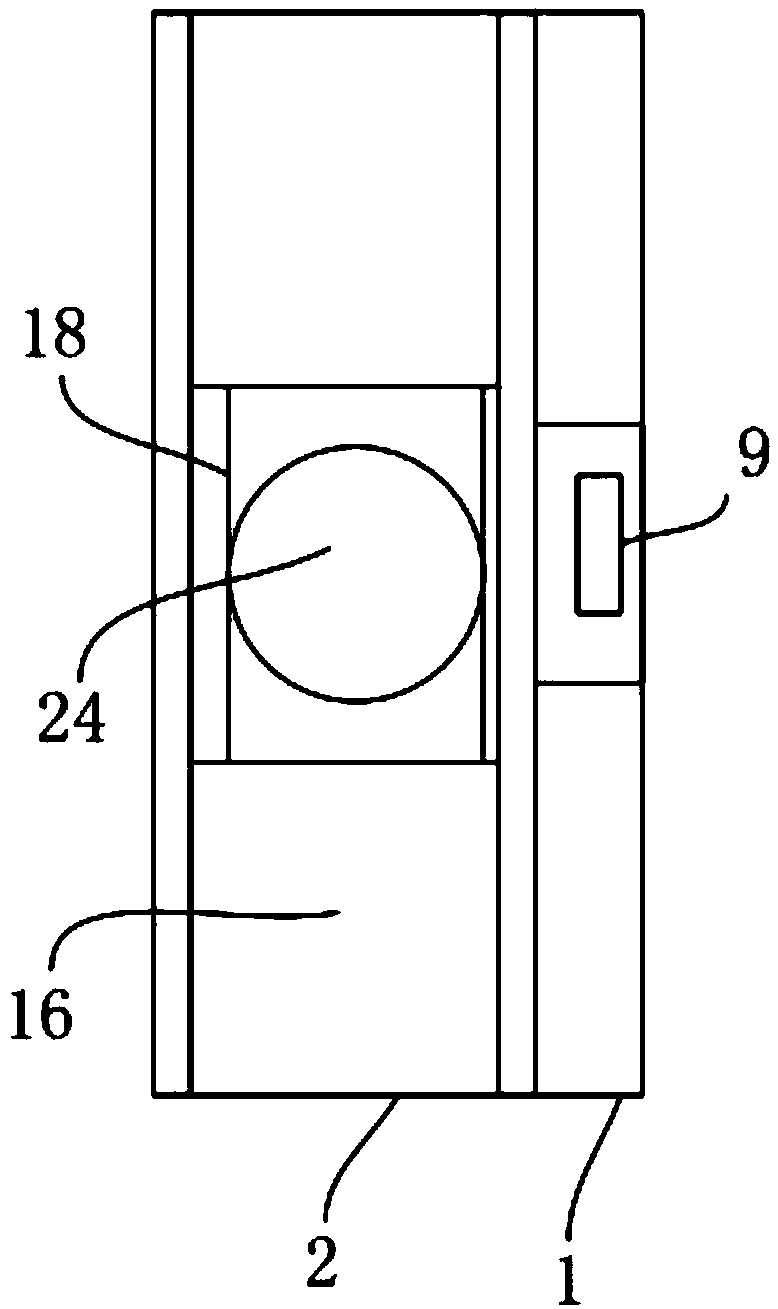

[0036] like Figure 1-4 As shown, a model high-precision positioning device suitable for five-axis CNC machining provided by the present invention includes: a machine tool 1, a mounting frame 2, a position sensor 3, a first mounting plate 5, a first positioning rotator 6, a second Positioning rotator 61, third positioning rotator 62, fourth positioning rotator 63, first mounting shaft 11, second mounting shaft 12, third mounting shaft 13, second mounting disc 8, fifth mounting shaft 15, Four installation shafts 14, clamping device 19, fixed table 18, rotator 24, positioning plate 17, moving mechanism 16, console 9, power module 10.

[0037] Further, as a preferred embodiment, the upper end of the machine tool 1 is provided with a mounting frame 2 , and the machine tool 1 is also provided with a console 9 , and the console 9 is located at one side of the mounting frame 2 . Preferably, the machine tool 1 has a cuboid structure.

[0038] Further, as a preferred embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com