Electric resistance welding micro-welding spot welding machine

A technology of resistance welding and welding points, which is applied in the field of micro-welding equipment, can solve the problems of inability to accurately control electrode force and less investment in manpower and material resources, and achieve the effects of avoiding hindering welding operations, improving verticality, and reducing losses or errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

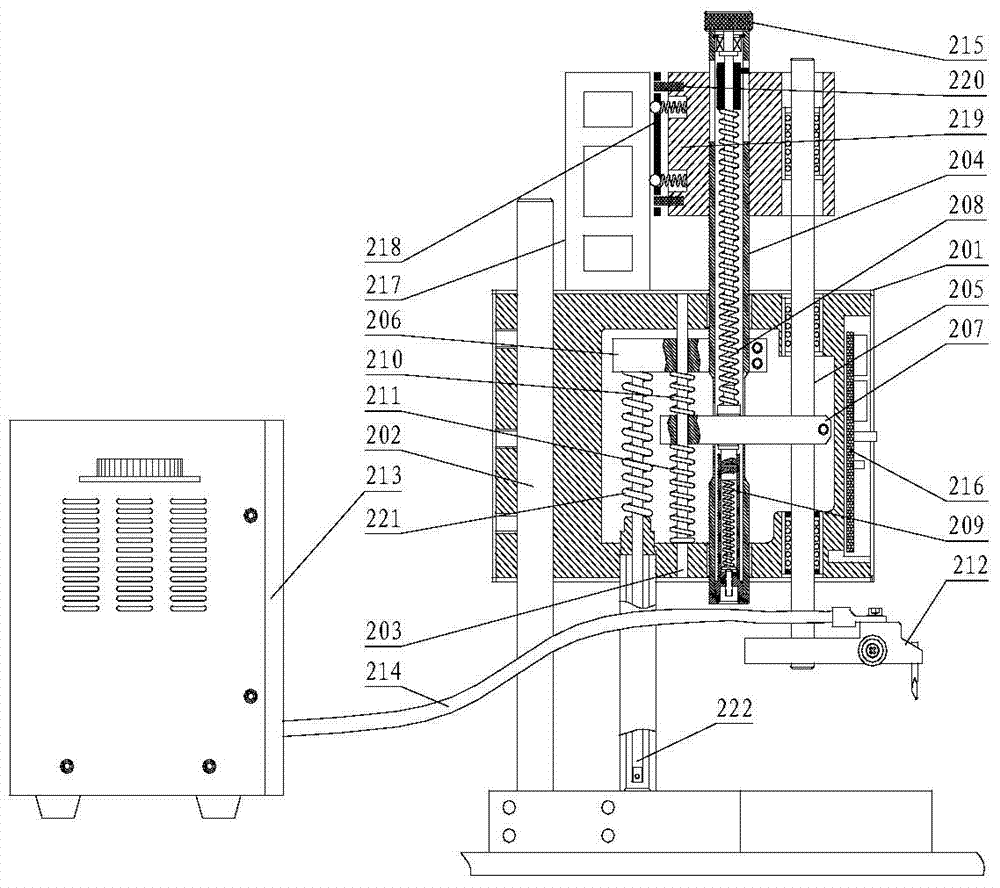

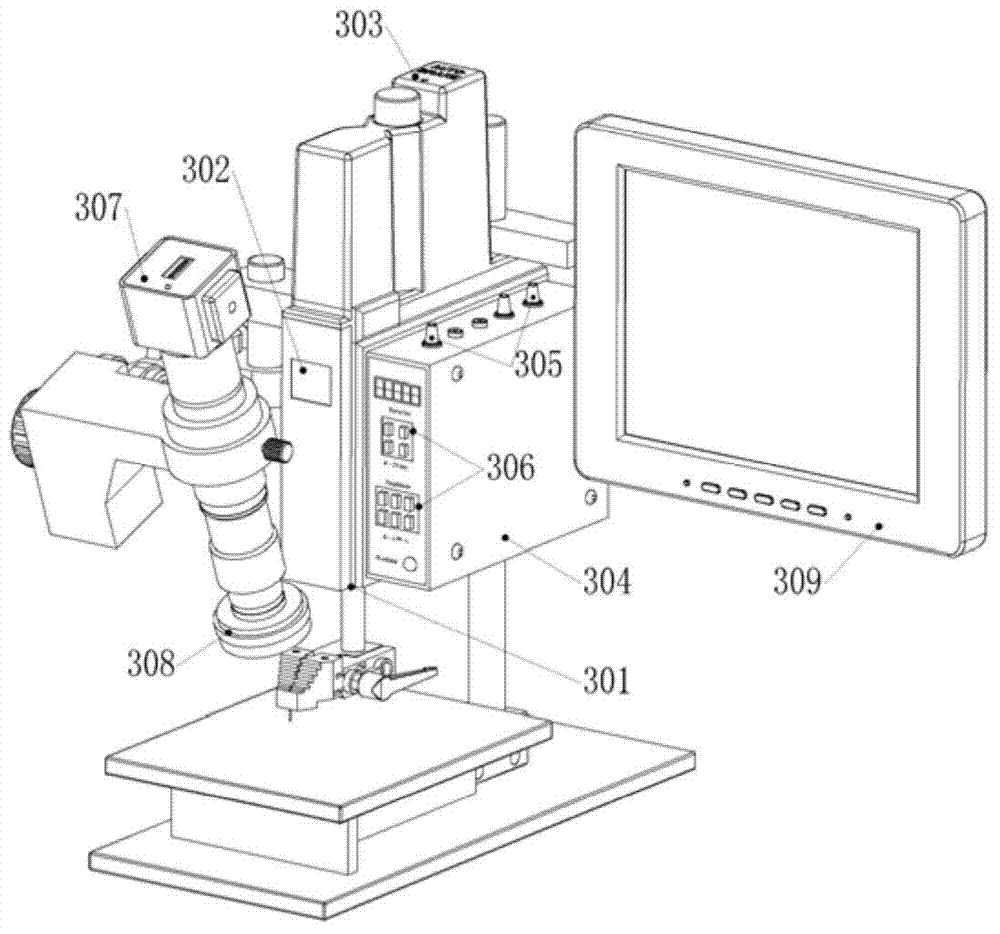

[0054] First of all, it needs to be understood that the concept of "resistance welding micro-welding" in the present invention is proposed for micro-workpieces that cannot be welded by resistance welding under direct vision. Resistance welding micro-welding not only needs to provide accurate electrode force and welding energy, Welding operations under micro-optical devices are also required. Due to space limitation, the present invention mainly introduces the head of the spot welding machine, the welding head clamp and the micro-optical device.

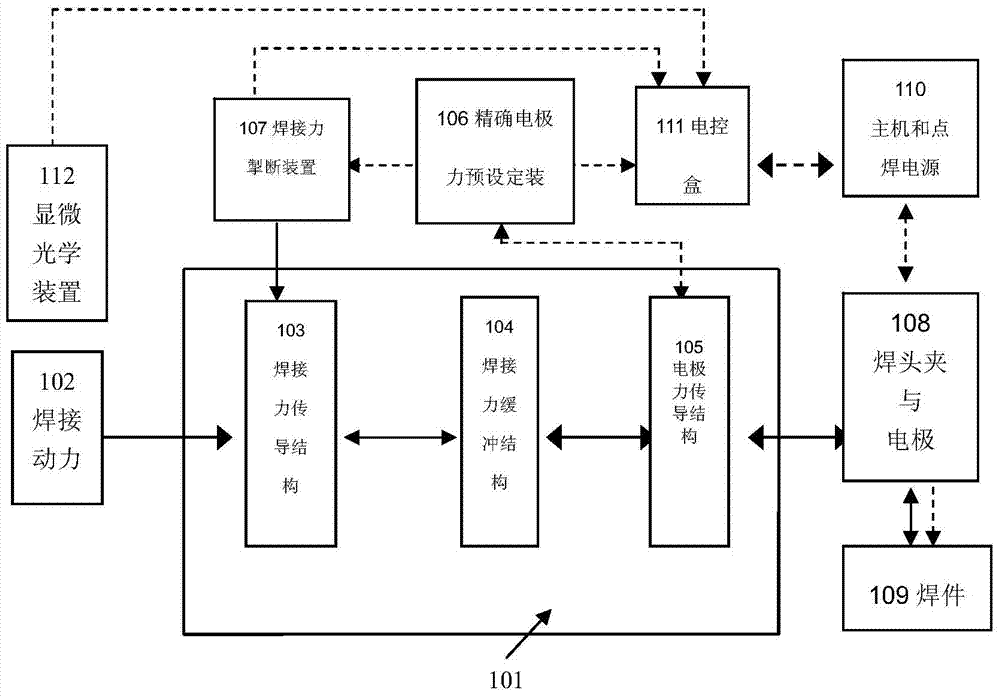

[0055] attached figure 1 Briefly introduce the general structural block diagram of the resistance welding microscopic welding spot welding machine of the present invention.

[0056] exist figure 1 Among them, the large box 101 represents the frame of the machine head, the small box 102 represents the welding power (welding force) provided by the external power source of the spot welder, 103 represents the welding force transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com