Base for pressurized bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

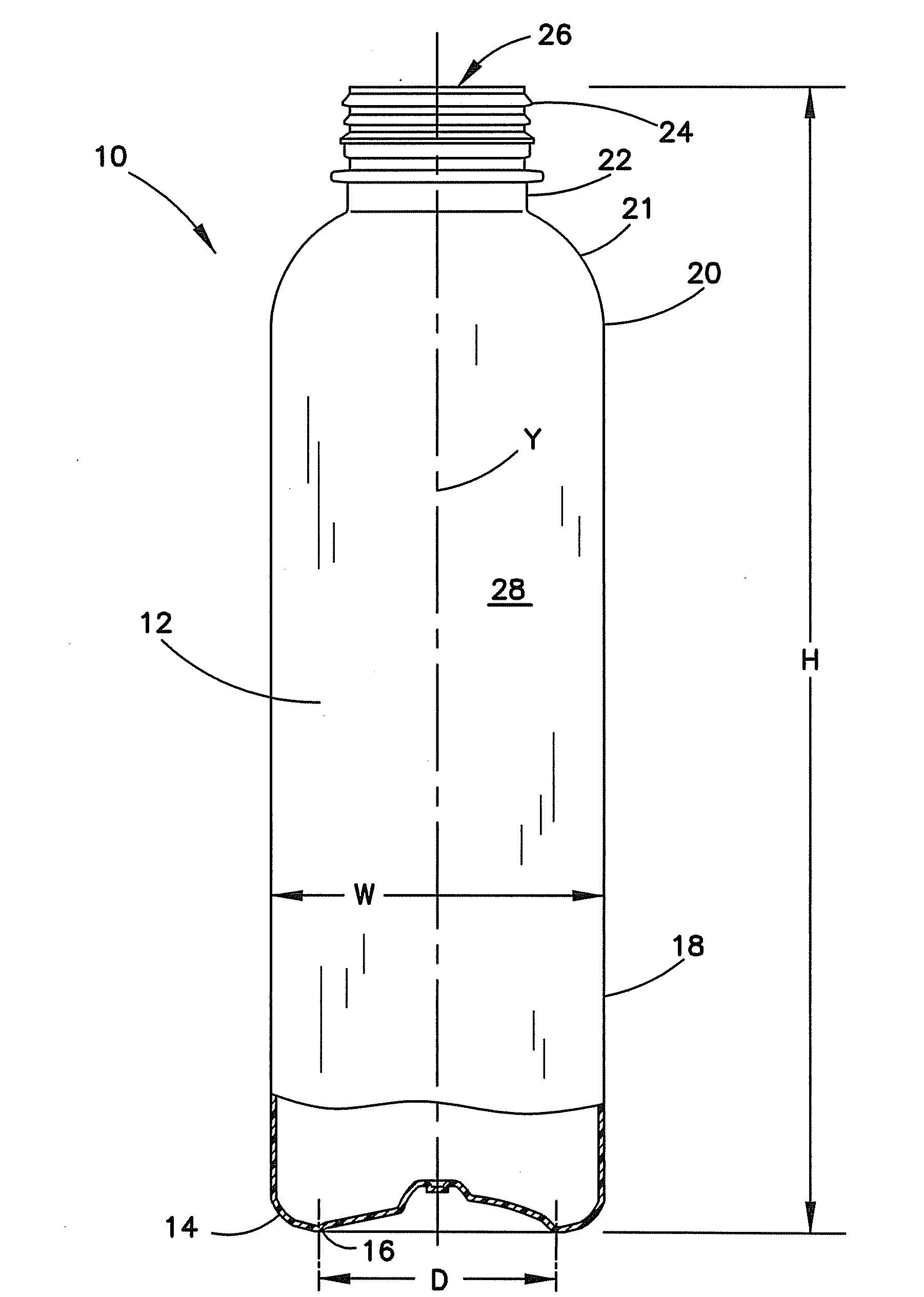

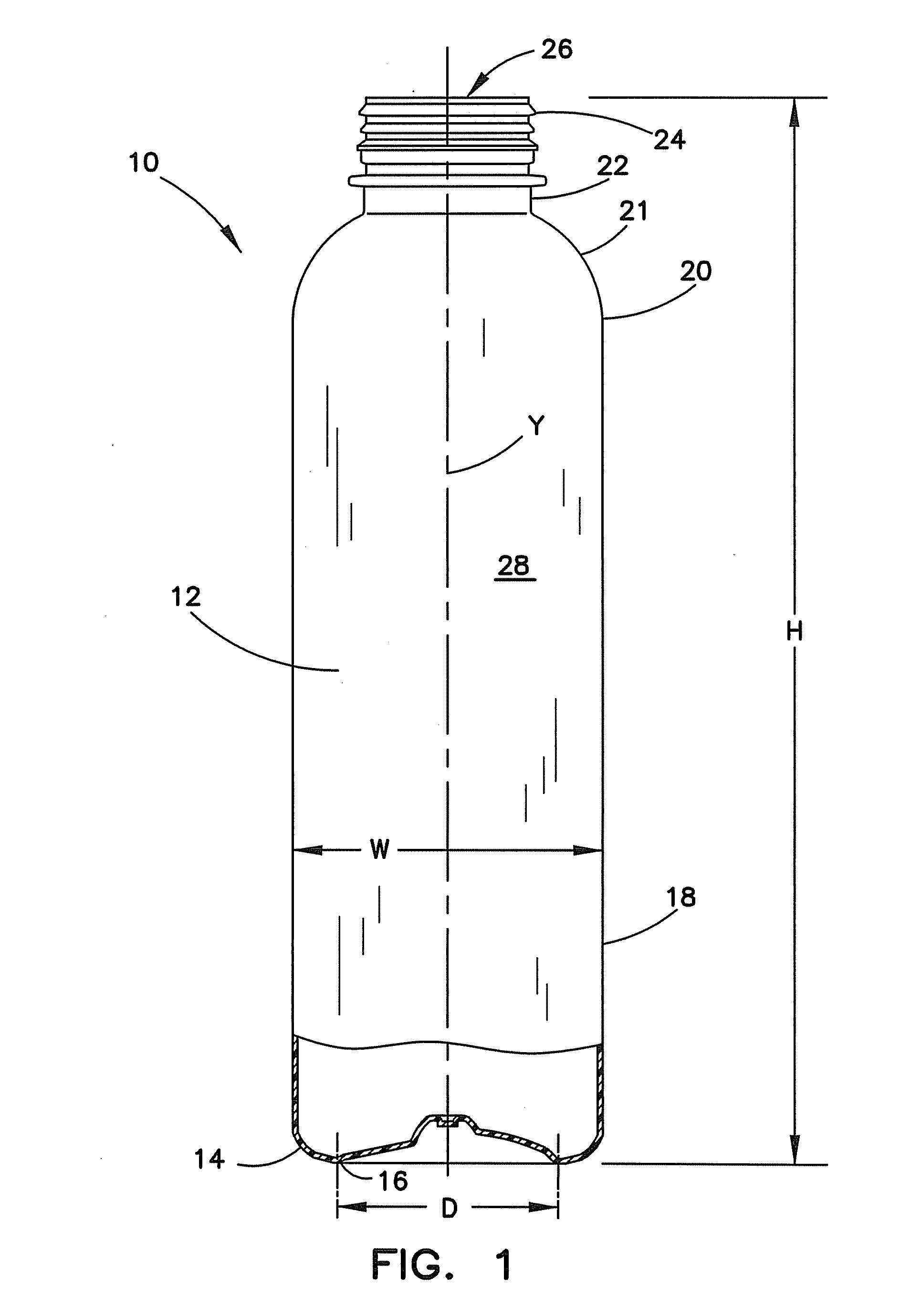

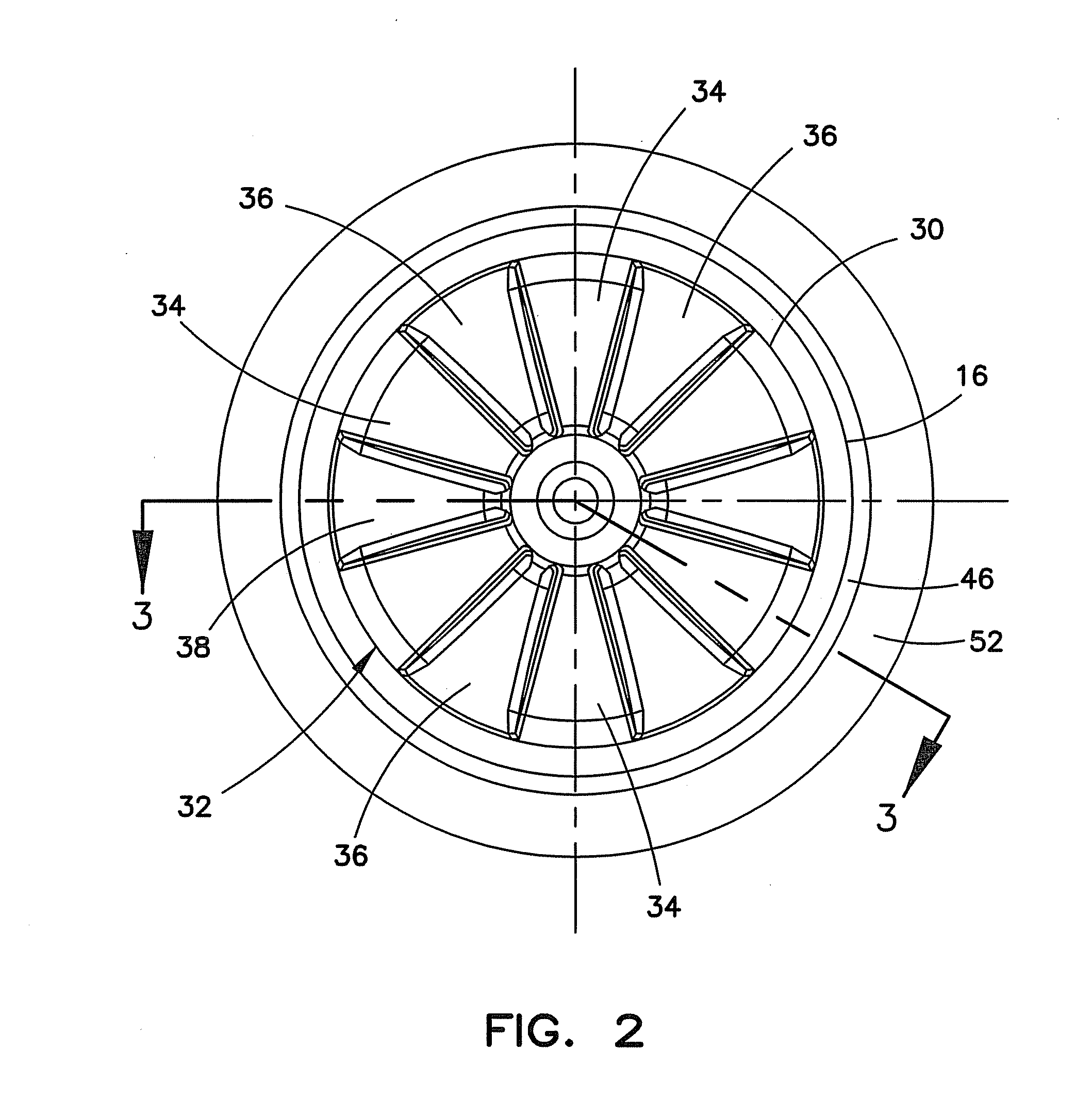

A bottle 10 is shown in FIG. 1 and the other Figs that has a generally cylindrical body 12 surrounding a longitudinal axis Y and a closed base 14 that is unitary with the remainder of the bottle. The 14 base has a continuous standing ring 16 to support the bottle 10 on any underlying support surface. The standing ring 16 has a standing ring diameter D. A side wall 18 is formed unitarily with the base 14 and extends from the base upward to an upper end 20 of the side wall 18. A neck 22 is unitarily connected to the upper end 20 of the side wall 18 by a shoulder portion 21. The neck 22 includes a finish 24 adapted to receive a cap (not shown) to close an opening 26 into the bottle interior 28. The bottle 10 has a height H defined by the distance between the opening 26 and the standing ring 16, and a maximum width W across the bottle 10.

To enhance the vertical alignment or perpendicularity of the bottle 10, the base standing ring 16 can be defined in vertical cross-section by a continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com