High-stability self-centering drill bit

A drill tip, high stability technology, used in drilling/drilling equipment, drill repair, drilling tool accessories, etc., can solve the problems of reduced accuracy, weak centering effect, long drill bit, etc., to improve the positioning effect , good positioning effect, high verticality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

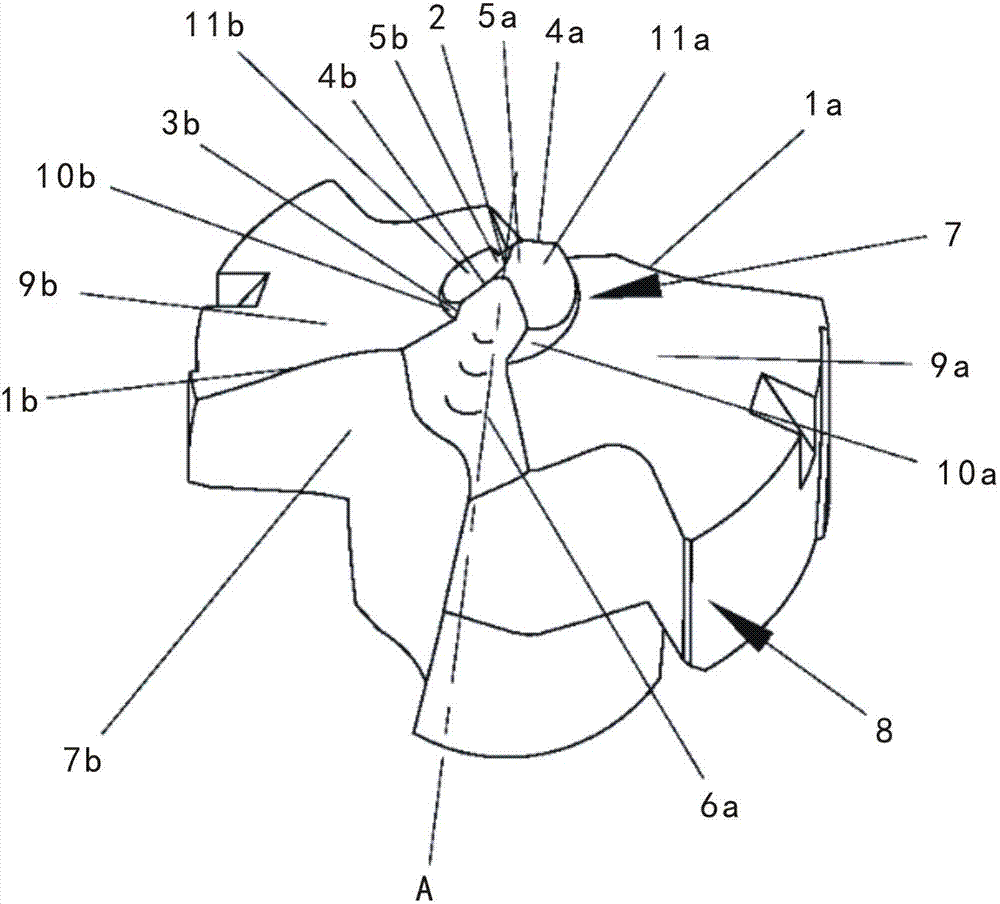

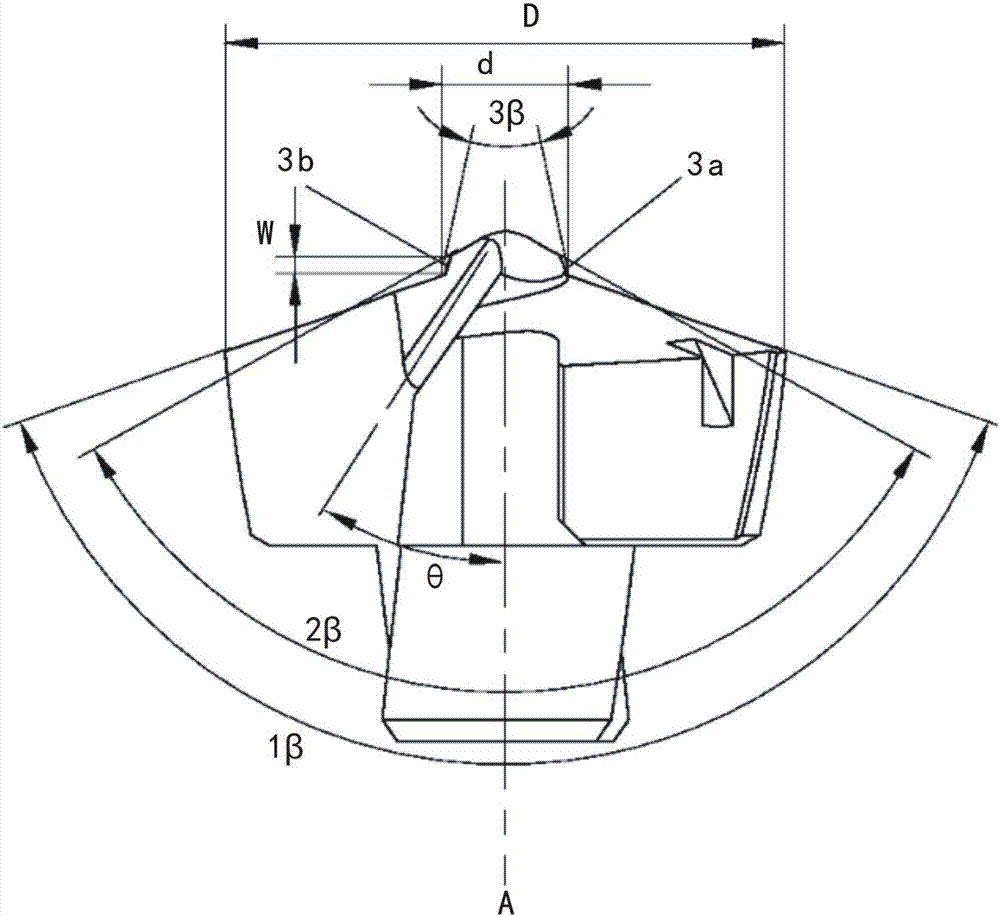

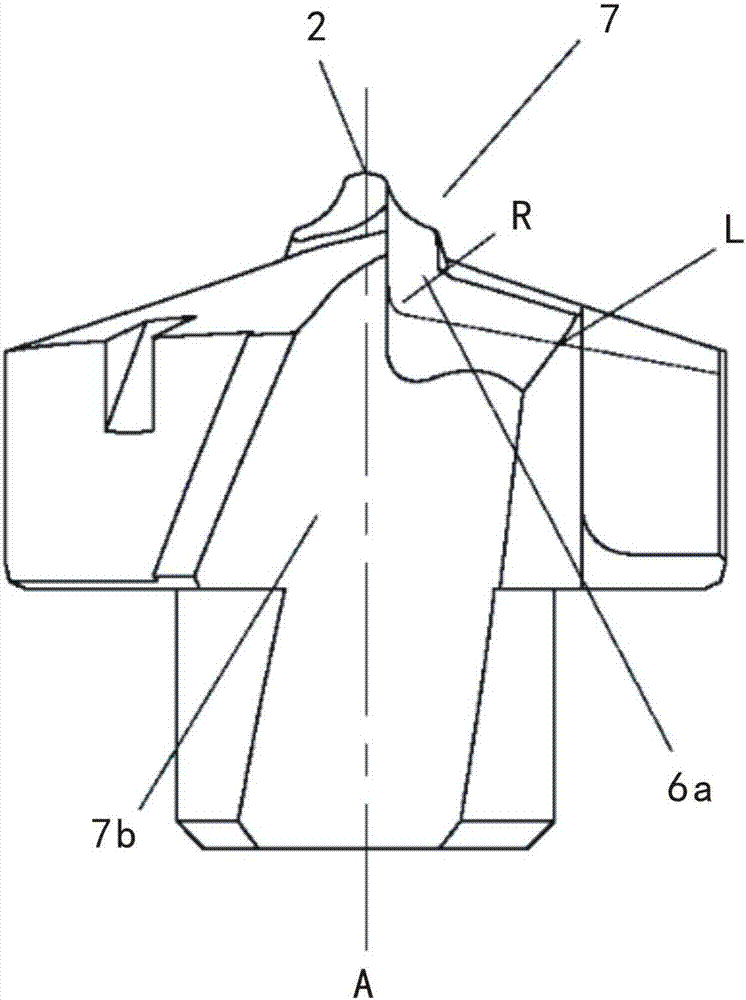

[0017] Such as Figure 1-Figure 4 As shown, the high stability self-centering drill bit 8 of the present invention is provided with two chip removal grooves 7a and 7b symmetrically on both sides, the tip of the drill tip 8 is upward, and the center of the drill tip 8 The position protrudes upwards along its center line to form a center tip 7, and the upper surfaces of the drill tip 8 located outside the two sides of the center tip 7 are outer flanks 9a and 9b respectively; the top of the center tip 7 is a line Shaped chisel edge 2, the two sides of the chisel edge 2 extend outwards and downwards in turn to be two chisel edges 5a / 5b, two inner flanks 11a / 11b and two oblique flanks 10a / 10b, the chisel edge 2 Two transition surfaces 6a and 6b are formed between the two ends of the two flutes 7a and 7b respectively, and the two transition surfaces 6a and 6b respectively inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com