Uniaxial micro-tensile test piece for thin film mechanical performance test

A micro-stretching and thin-film technology, which is applied in the field of uniaxial micro-stretching specimens, can solve the problems of non-silicon materials that are not suitable for measuring large plastic deformation, unsuitable for routine operations, and limited application scope, and achieves high yield, High verticality and the effect of solving measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

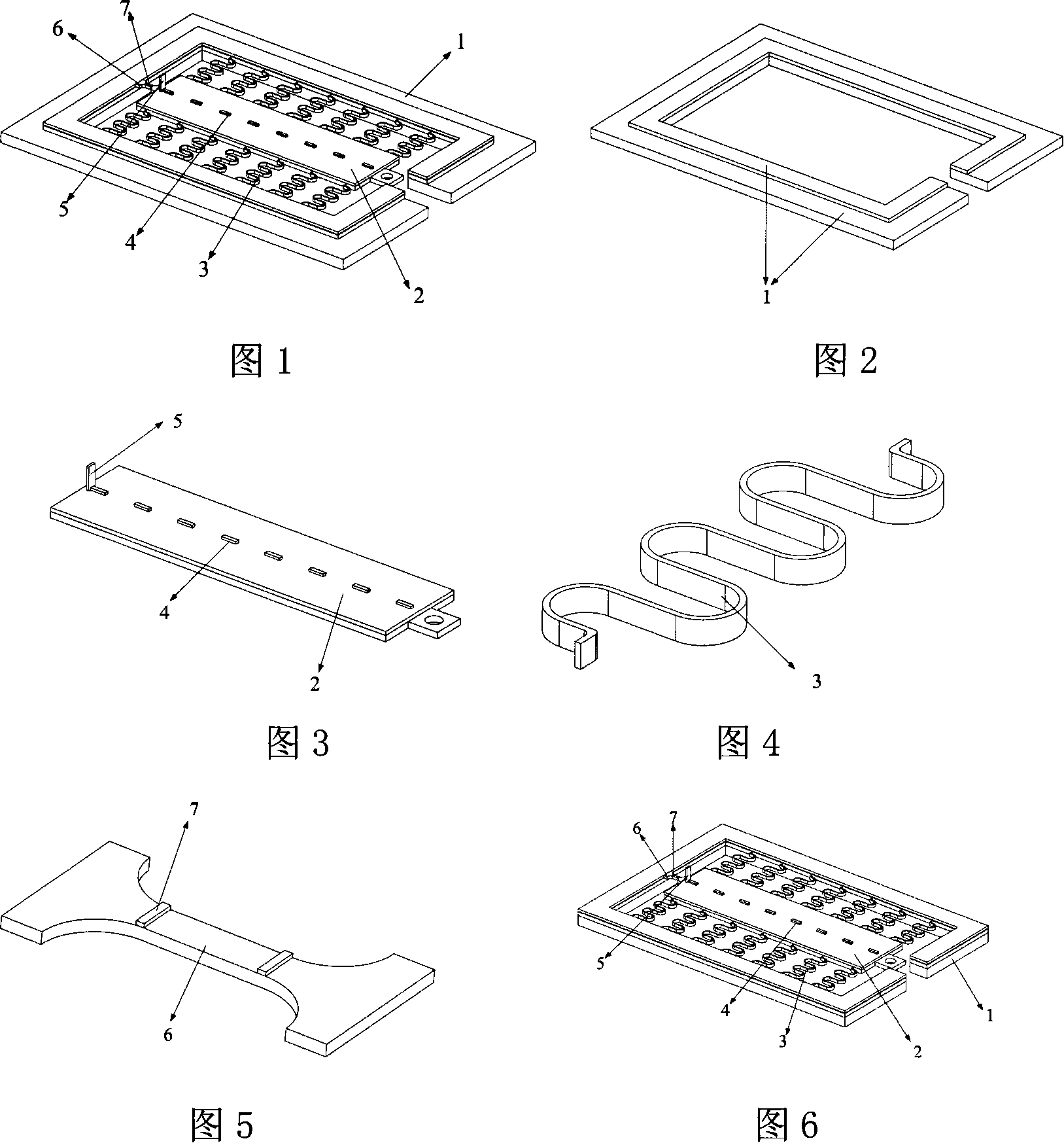

[0021] Example 1 has a micro-tensile specimen structure with silicon and nickel U-shaped support structures.

[0022] As shown in FIG. 1 , this embodiment includes: a U-shaped support platform 1 , a mobile platform 2 , a snake-shaped support spring 3 , a centering mark 4 , and a displacement mark 5 . The serpentine support spring 3 is connected to the U-shaped support platform 1 and the mobile platform 2, and the two ends of the film sample 6 are connected to the U-shaped support platform 1 and the mobile platform 2 in the air respectively. The centering mark 4 is located on the top of the mobile platform 2, and the displacement mark 5 is bonded to the tail end of the film sample 6 and the mobile platform 2. During the measurement, the U-shaped support platform 1 is fixed on the metal base, and the other end of the mobile platform 2 is connected to the The load sensors are connected to each other, and a tensile force in the horizontal direction is applied to the mobile platfor...

Embodiment 2

[0036] Embodiment 2 has a micro-tensile specimen structure with silicon and nickel U-shaped support platforms.

[0037] The material and structure of this embodiment are the same as those of Embodiment 1, but the dimensional parameters of each part are different.

[0038] In this embodiment, the lower layer of the U-shaped support platform 1 is monocrystalline silicon with a thickness of 500 microns, and the peripheral dimensions are 17 mm long, 17 mm wide, and the width of the support beam is 3 mm; the peripheral dimensions of the upper layer are 15 mm long, 15 mm wide, and the width of the support beam 2mm;

[0039] In this embodiment, the mobile platform 2 is 12.5 mm long and 2.5 mm wide, the thickness and material are the same as those of the U-shaped support platform, and the diameter of the front circular through hole is 1 mm;

[0040] In this embodiment, the serpentine support spring 3 has a line width of 50 microns, a thickness of 200 microns, an arc inner diameter of...

Embodiment 3

[0043] Embodiment 3 has the micro-tensile specimen structure of metal nickel U-shaped support platform.

[0044] As shown in FIG. 6 , the structure of the micro-tensile test piece in this embodiment includes: a U-shaped support platform 1 , a mobile platform 2 , a serpentine support spring 3 , a centering mark 4 , and a displacement mark 5 . The material and structure of other components are basically the same as those in Embodiment 1 except for the size parameters, the U-shaped support platform 1 and the mobile platform 2 which are all formed of electroplated nickel metal.

[0045] In this embodiment, the outer dimensions of the U-shaped support platform 1 are 14 mm long, 14 mm wide, 2 mm wide, and 450 microns thick;

[0046] In this embodiment, the mobile platform 2 is 10 mm long and 3 mm wide, with the same thickness and material as the U-shaped support structure, and the diameter of the front circular through hole is 1 mm;

[0047] In this embodiment, the serpentine suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com