Saw grooving machine

A technology for slotting machines and submersible motors, which is applied to earth movers/excavators, construction, etc. It can solve the problems of slow slotting speed, high equipment maintenance costs, and high cost, and achieve high verticality, stable operation, and smooth slotting. The effect of smooth and flat walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

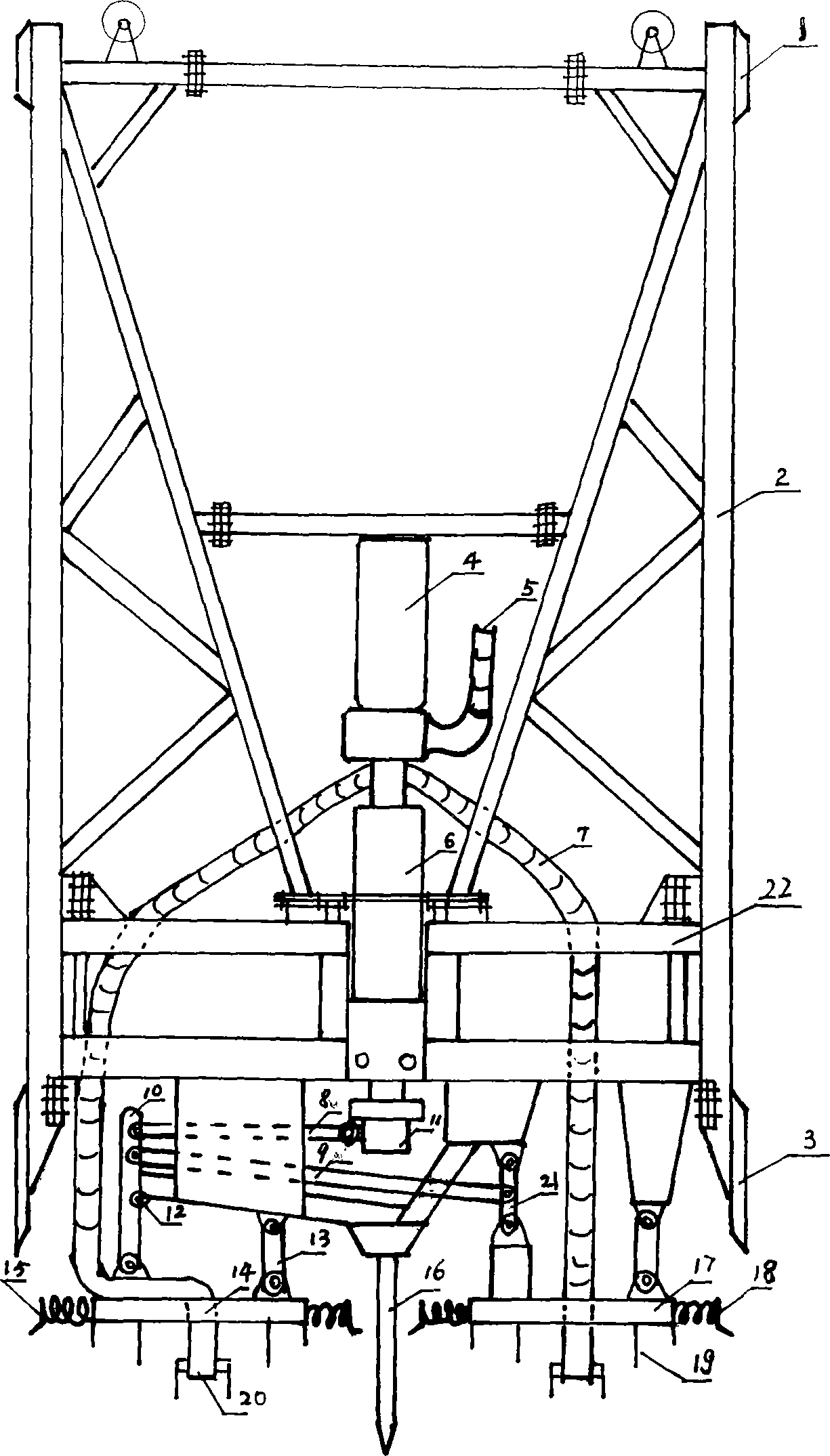

[0019] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a horizontal frame 22, guide rods 2 arranged vertically on both sides, a submersible motor 6 located in the center of the horizontal frame 22, and a submersible gravel pump 4 connected to the submersible motor 6. The submersible gravel pump 4 is connected to the sand outlet pipeline. 5. The sand suction pipe 7, the sand suction port 20 of the sand suction pipe 7 is located at the bottom, the upper and lower ends of the guide rod 2 are respectively provided with an upper guide plate 1 and a lower guide plate 3; the lower end of the submersible motor 6 is equipped with a crank 11 , the left and right sides of the bottom of the crank 11 are respectively provided with a cutter bar A14 and a cutter bar B17, and a positioning pin 16 is arranged at the central position between the cutter bar A14 and the cutter bar B17; Plate 19, crank 11 is connected with connecting rod A8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com