Outer-pipe circular cutting robot for steel pipe

A technology of robots and steel pipes, applied in the field of robots, can solve the problems of low processing efficiency and achieve the effects of fast cutting speed, improved cutting efficiency, and neat cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

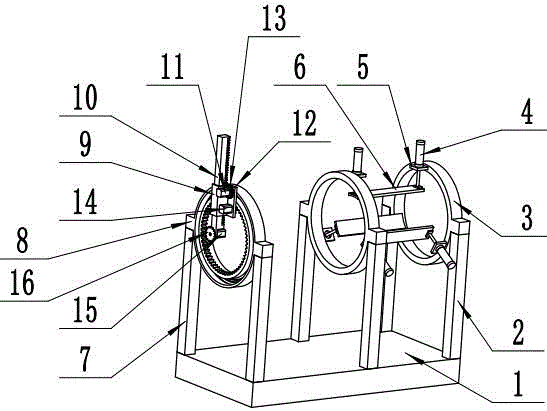

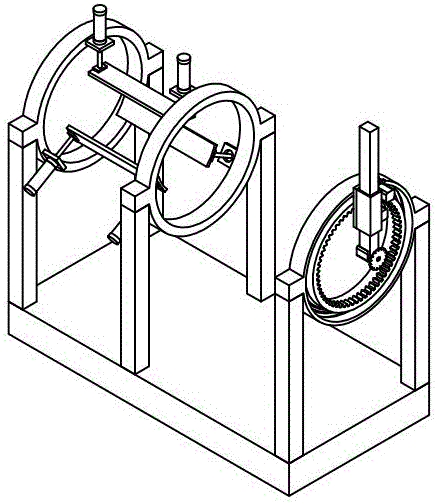

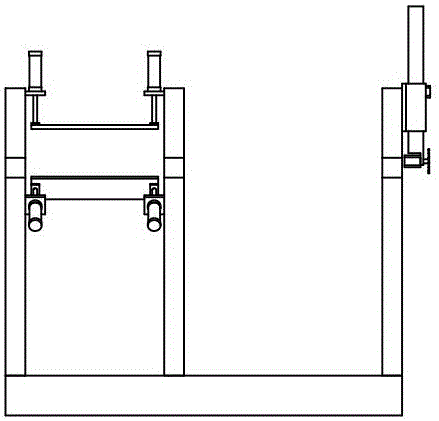

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown in the figure, a steel pipe outer ring cutting robot includes a base 1, four steel pipe frame columns 2, two steel pipe fixing sleeves 3, six hydraulic cylinders 4, six hydraulic cylinder fixing seats 5, three steel pipe pressure plates 6, Two ring cutting frame columns 7, ring cutting frame 8, telescopic rod sleeve 9, telescopic rod 10, telescopic rod motor 11, cutting mechanism fixing plate 12, telescopic motor gear 13, rotating motor 14, cutting motor 15, cutting blade 16 , motor gear 17, arc card plate column 18, arc card plate 19, electric brush 20, telescopic rod rack 101, telescopic rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com