a pipe joint

A technology of pipe joints and connecting parts, applied in the field of pipe joints, can solve the problems of liquid leakage, affect the progress of construction, increase the scrap rate, etc., and achieve the effects of accurate installation, increased utilization rate, and reduced scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

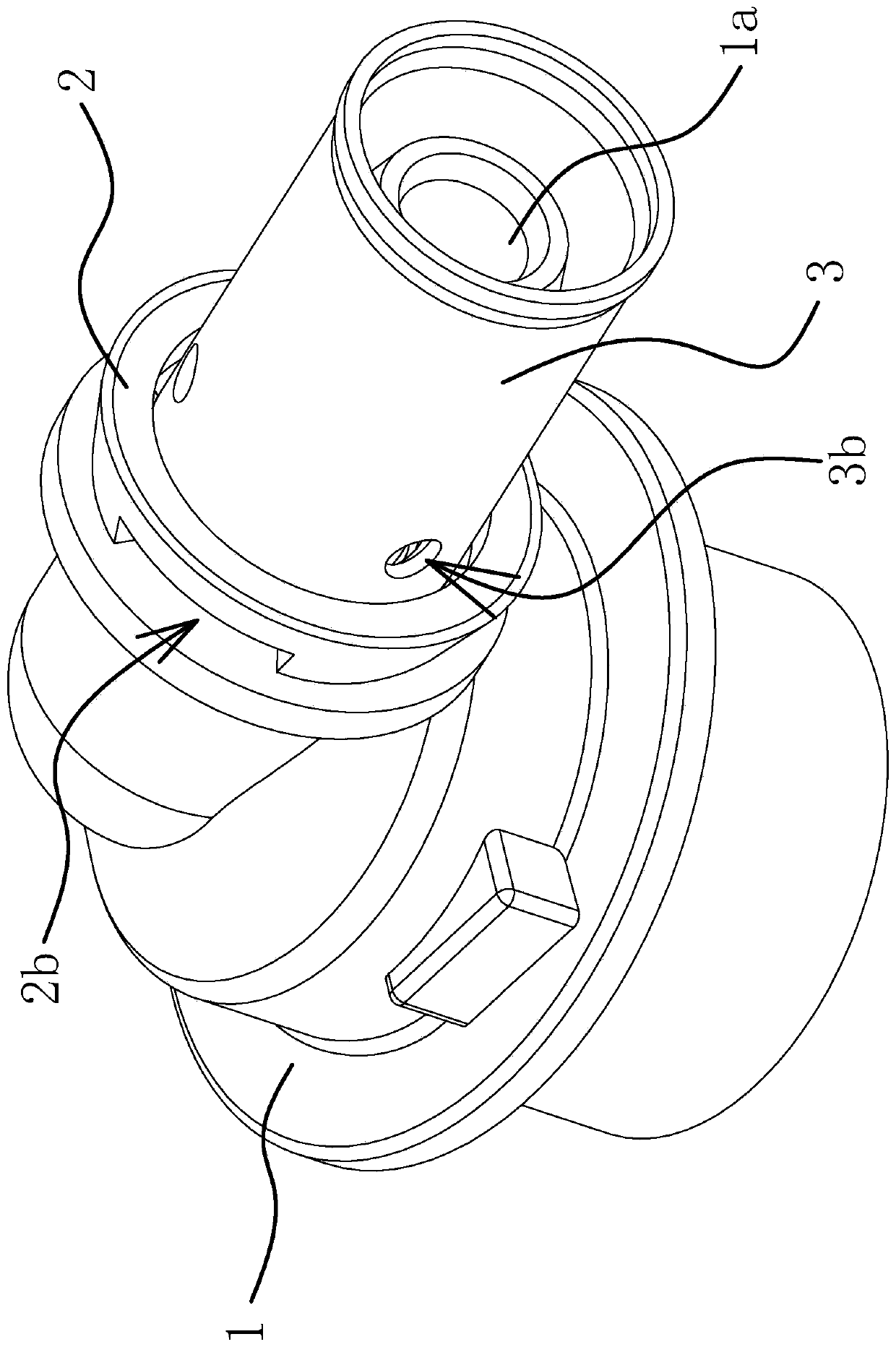

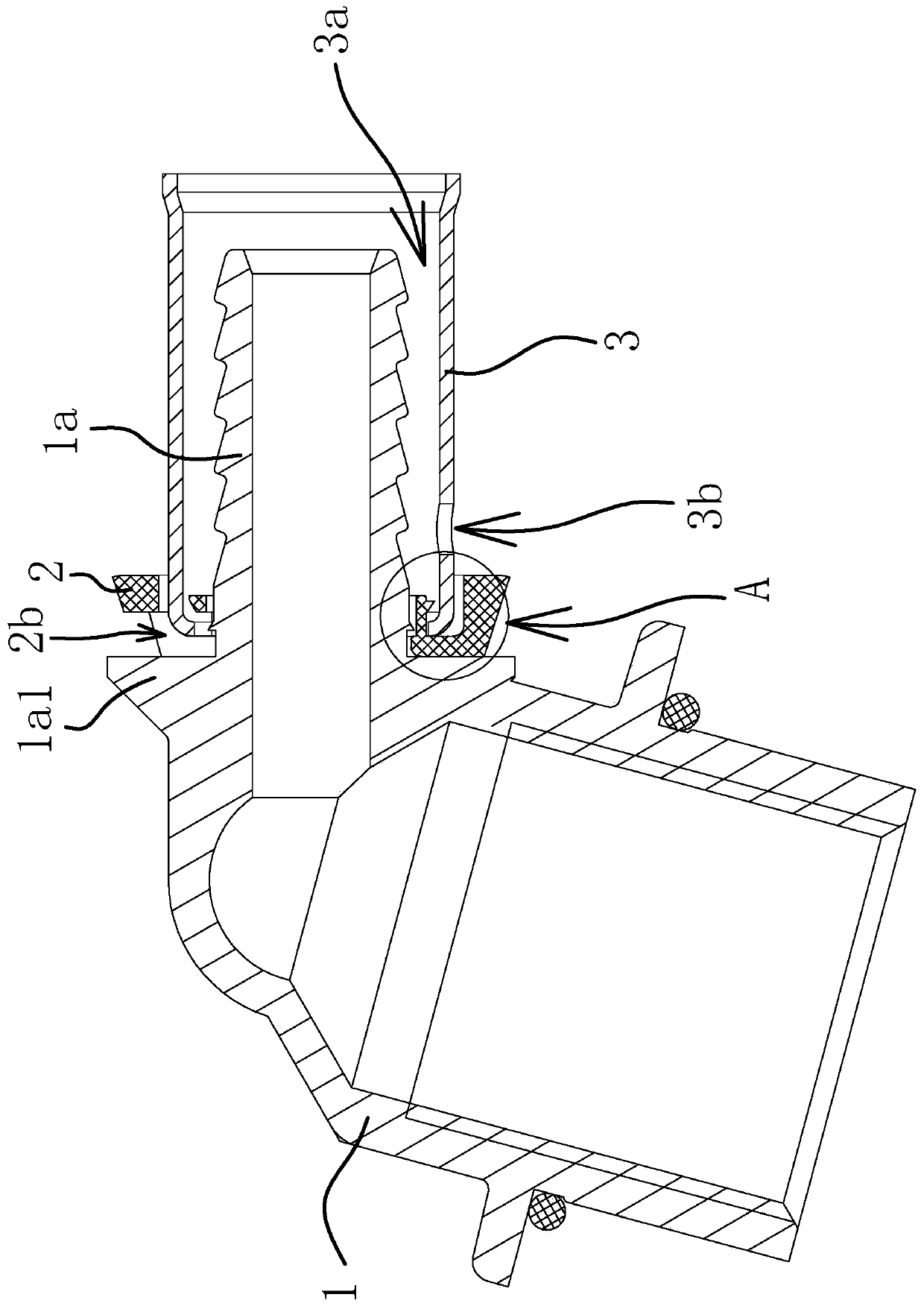

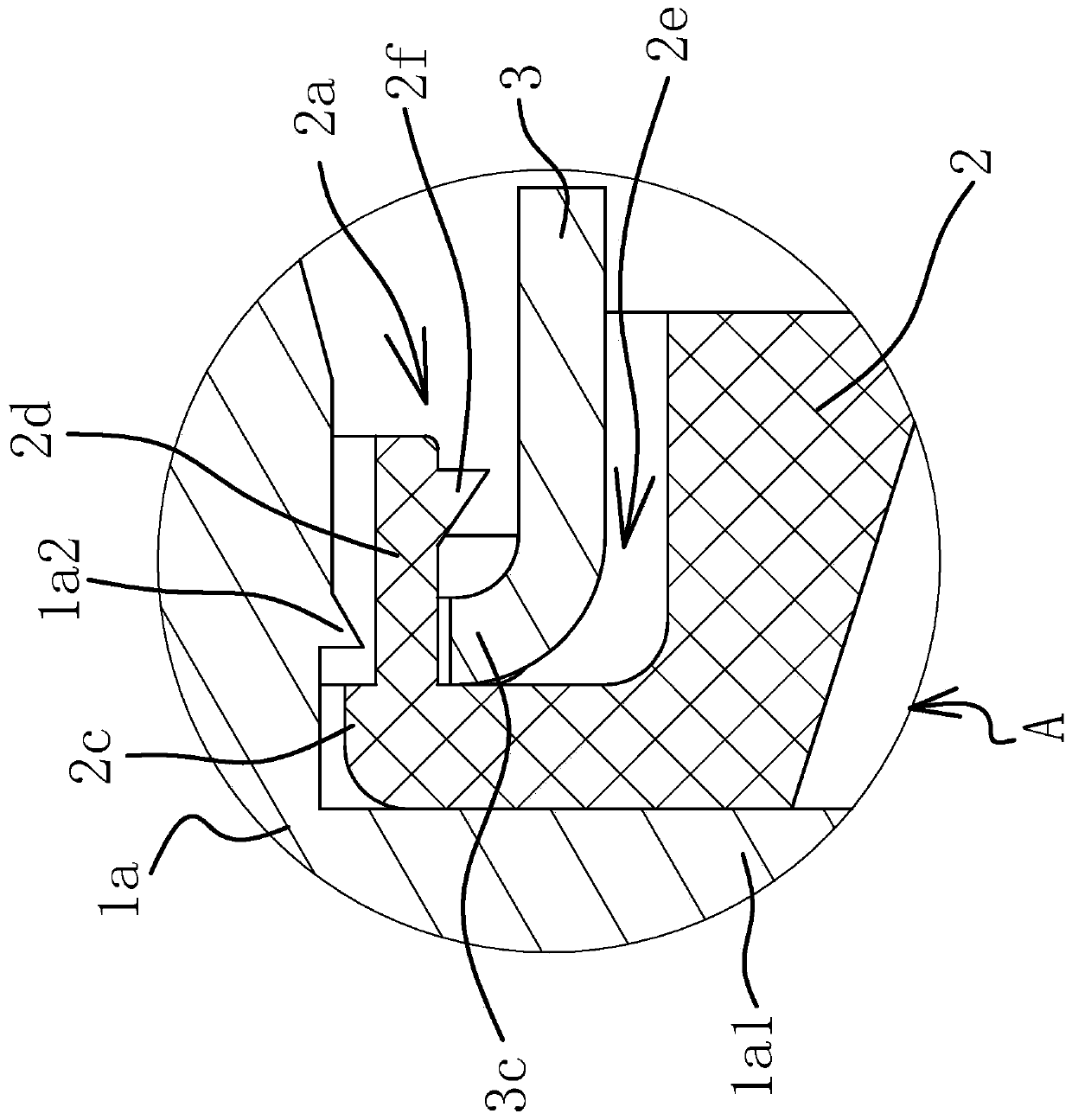

[0036] Such as Figure 1-Figure 6As shown, a pipe joint includes a joint body 1. The joint body 1 is generally made of hard materials such as copper or steel. The end of the joint body 1 has a connecting portion 1a for connecting with a pipe 4. The pipe 4 is generally plastic pipe. A protruding annular shoulder 1a1, an annular protruding ring 1a2 and a fixing part are sequentially provided on the outer surface of the connecting part 1a from the inner end to the outer end of the connecting part 1a, and the diameter of the outer surface of the protruding ring 1a2 is along the connecting part 1a. The direction from the inner end to the outer end gradually decreases, and the outer surface of the fixing part is wavy. The outer surface and the outer end surface of the connecting portion 1a are rounded, which facilitates the fitting of the tube 4 onto the connecting portion 1a. A collar 2 and a ferrule 3 are sheathed on the connecting portion 1a, and both the collar 2 and the ferru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com