pressure limiting valve

A pressure-limiting valve and valve technology, applied in control valves, safety valves, balance valves, etc., can solve problems such as damage and failure of pressure-limiting valves, and achieve the effect of weakening axial movement and high antifouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] For the following description, it needs to be emphasized that the present invention is not limited to the embodiments, and therefore is not limited to all or more features in the described combination of features, more precisely, each individual in any embodiment A sub-feature still has the meaning according to the invention, whether alone or in combination with any feature in another embodiment, separately from all other sub-features described in combination.

[0077] In the different drawings, the same components are provided with the same reference numerals and are therefore usually only described once.

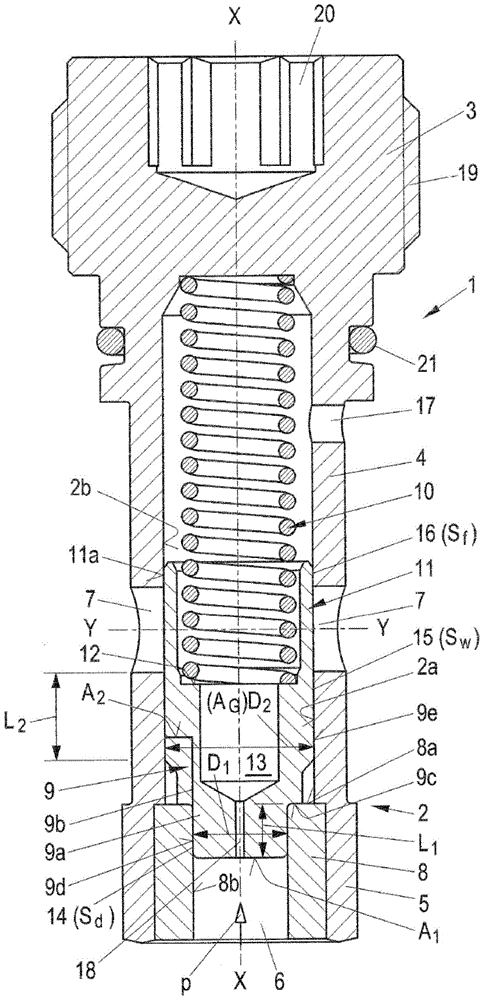

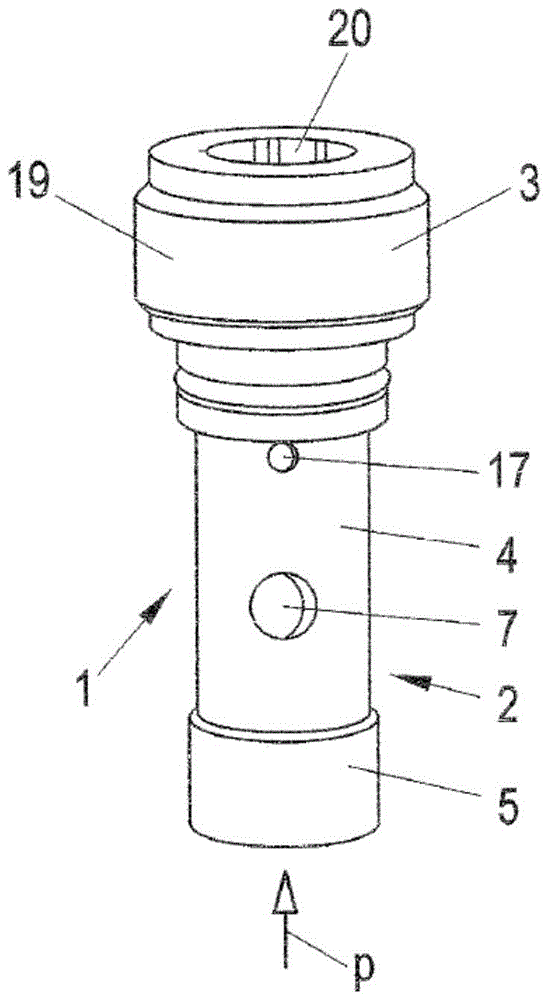

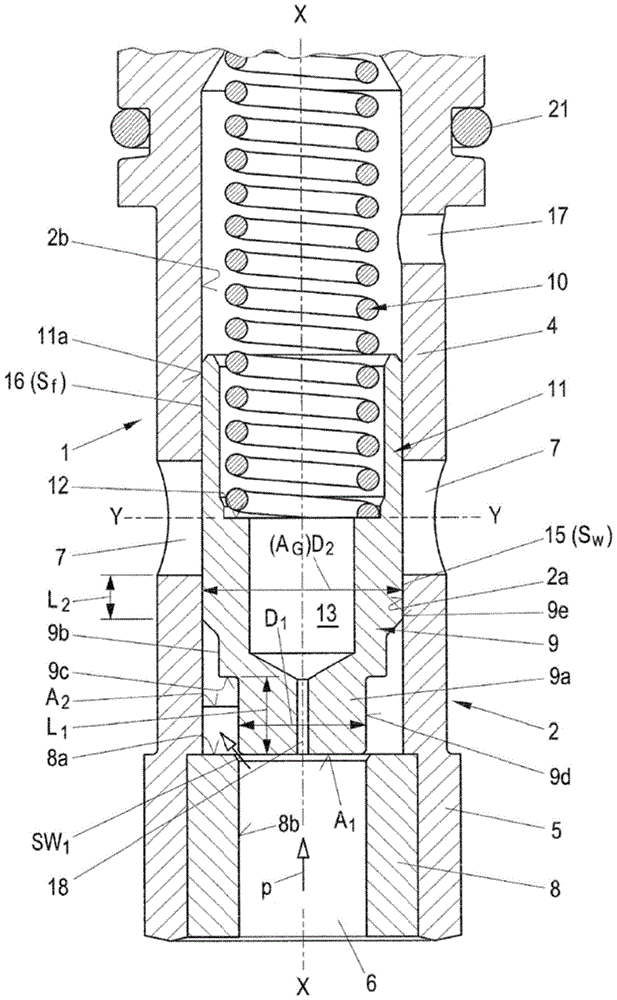

[0078] as first in figure 1 and figure 2 As shown in the course, the Figure 3 to Figure 5 as well as Figure 7 It can also be seen in , that the pressure limiting valve 1 according to the invention can be installed in particular in the return line of a common rail system of an internal combustion engine, which has a valve housing 2 . Valve housing 2 includes h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com