Cold rolled uncoiler drum support roller

A technology for supporting rolls and machine coils, applied in the field of cold-rolled strip steel equipment, can solve the problems of inability to meet the needs of strip steel production, equipment shutdown and maintenance, serious economic losses, etc., to improve production efficiency, solve axial movement, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

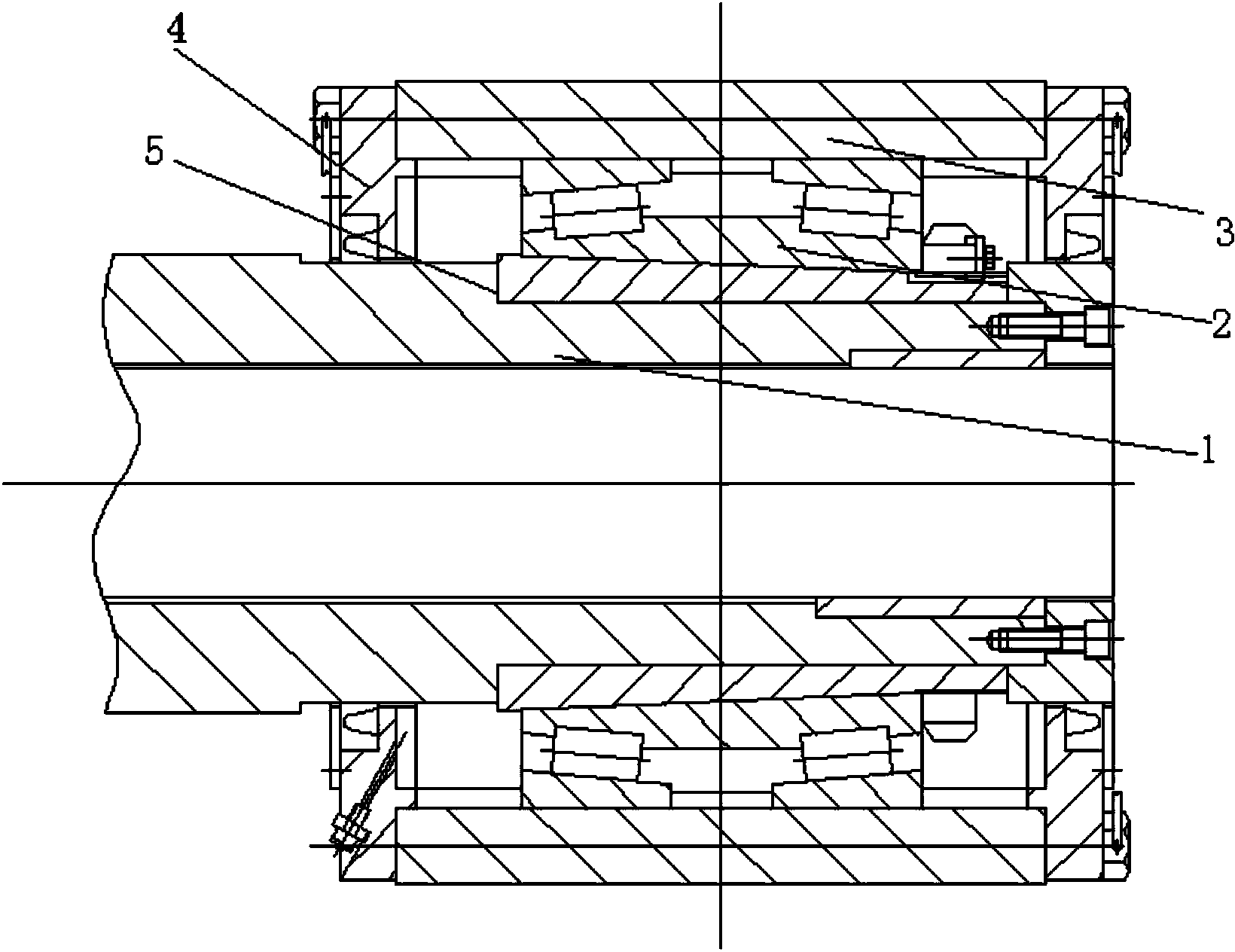

[0014] Referring to the accompanying drawings, the supporting roll on the reel of the cold rolling uncoiler includes a main shaft 1, the end of the main shaft 1 is equipped with an adapter sleeve tapered roller bearing 2, and the adapter sleeve tapered roller bearing 2 is equipped with a roller 3, The two ends of the adapter sleeve tapered roller bearing 2 are respectively equipped with glands 4 , the main shaft 1 is provided with a stepped surface 5 , and the adapter sleeve tapered roller bearing 2 is fitted on the stepped surface 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com