Electrical drive grab dredger

An electric drive, dredger technology, applied in mechanically driven excavators/dredgers, motor vehicles, special-purpose ships, etc., can solve the problems of complex mechanism layout and key technology monopoly, and achieve large overload coefficient, operation control and other problems. The effect of good performance and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is described in further detail:

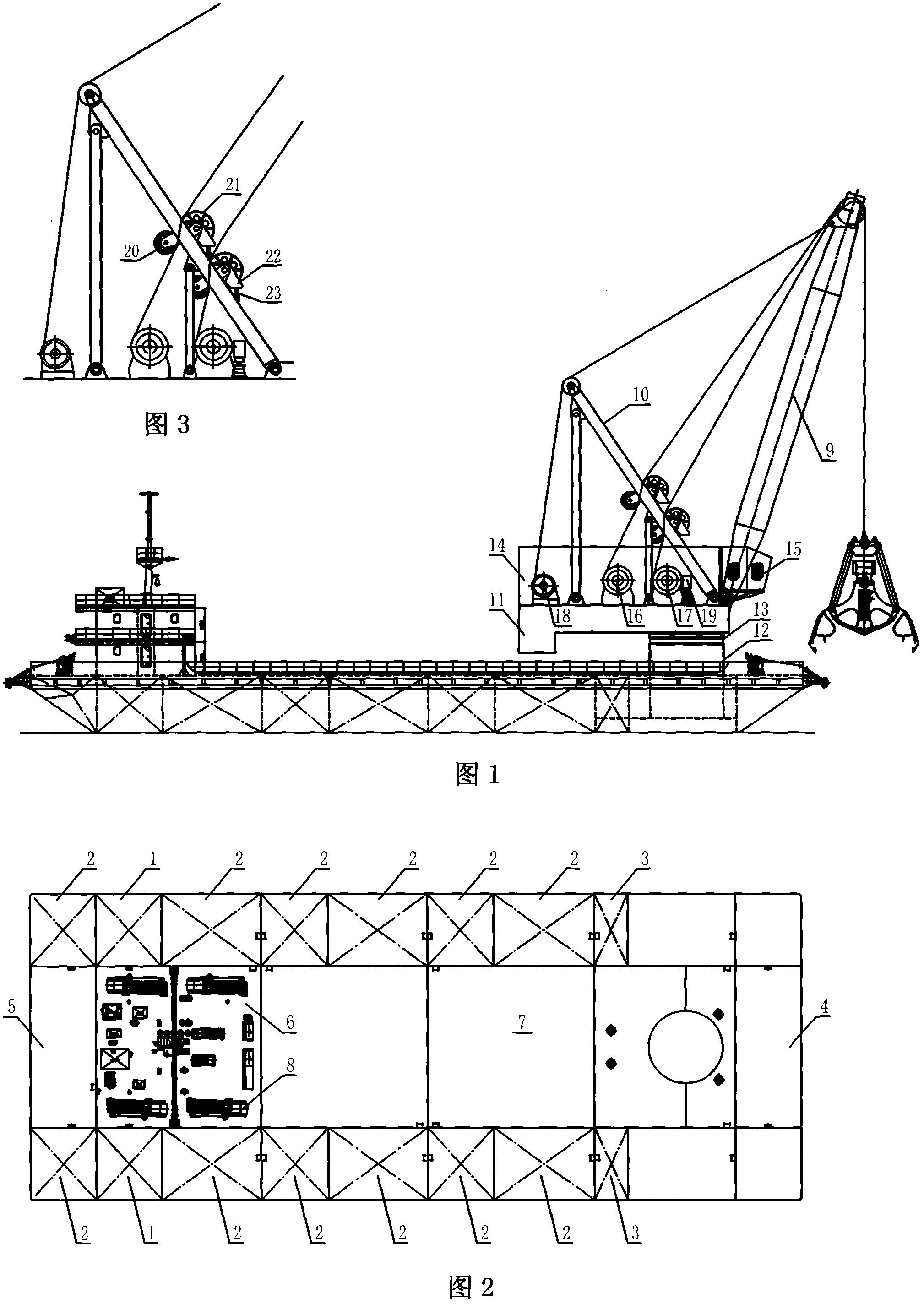

[0029] Such as figure 1 , 2 As shown, the 18m of this embodiment 3 The electric drive grab dredger consists of two parts: the hull and the grab dredger, and the dredge is installed on the deck of the hull.

[0030] In the hull of the present invention, diesel tanks (1), ballast water tanks (2), and cooling water tanks (3) are arranged on both sides, forepeak tanks (4) and stern peak tanks (5) are arranged at both ends, and the middle is arranged Auxiliary engine room (6) and empty cabin (7), arrange diesel generator set (8) in the auxiliary engine room (6), be responsible for supplying power to the grab dredger on deck.

[0031] The dredger of the present invention is made up of boom (9), herringbone frame (10), turntable (11), slewing bearing (12) and base (13) five parts, and slewing bearing (12) will dredge The rotary part of the machine is supported on the fixed base (13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com