Flat plate cleaning machine

A cleaning machine and flat panel technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as complex structure, dirty sticky dust, uneven products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

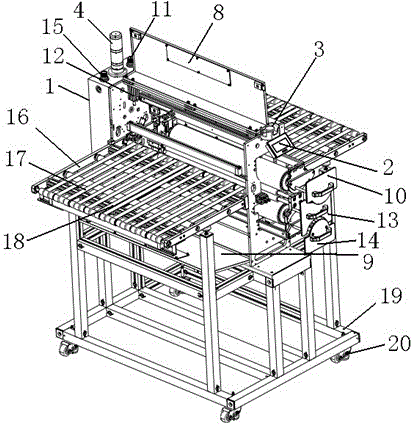

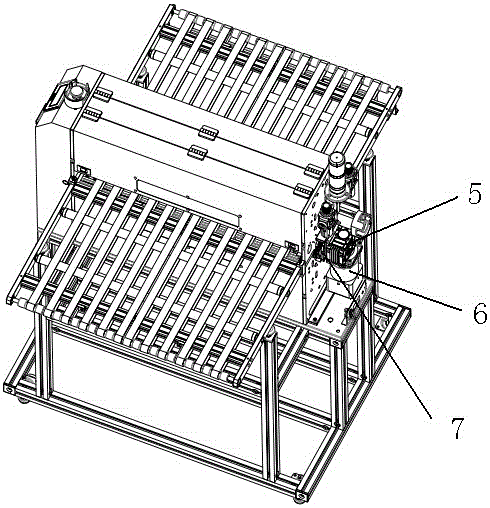

[0030] A flatbed cleaner, see attached Figure 1-2 ,include:

[0031] Frame 19, which is supported by casters 20 arranged around its lower part;

[0032] The fuselage 1, which is arranged on the frame, is provided with an operation panel 2 for display and control, an emergency stop button 3 for cutting off the power supply, and a warning light 4 for flashing alarm;

[0033] A speed-regulating motor 6, which is located inside the fuselage, is connected with a reducer assembly 5 and a gear assembly 7;

[0034] Conveyor frame 16, several elastic tension conveyor belts 17, and photoelectric sensor 18 are housed on it;

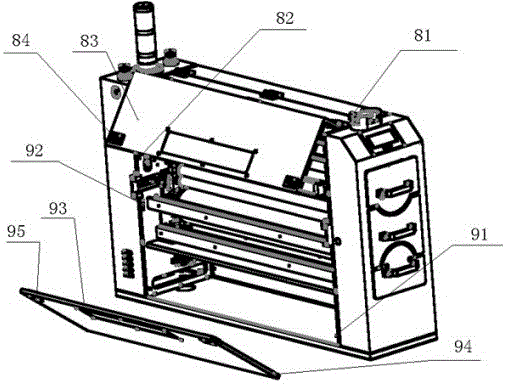

[0035] Upper observation window assembly 8, which is located above the conveying frame in a freely openable and closable manner;

[0036] The lower viewing wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com