Heat treatment method of high-silicon steel plate strip material

A heat treatment method and steel strip technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of several times difference in thermal efficiency, and achieve the effects of reducing strength, increasing plasticity, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

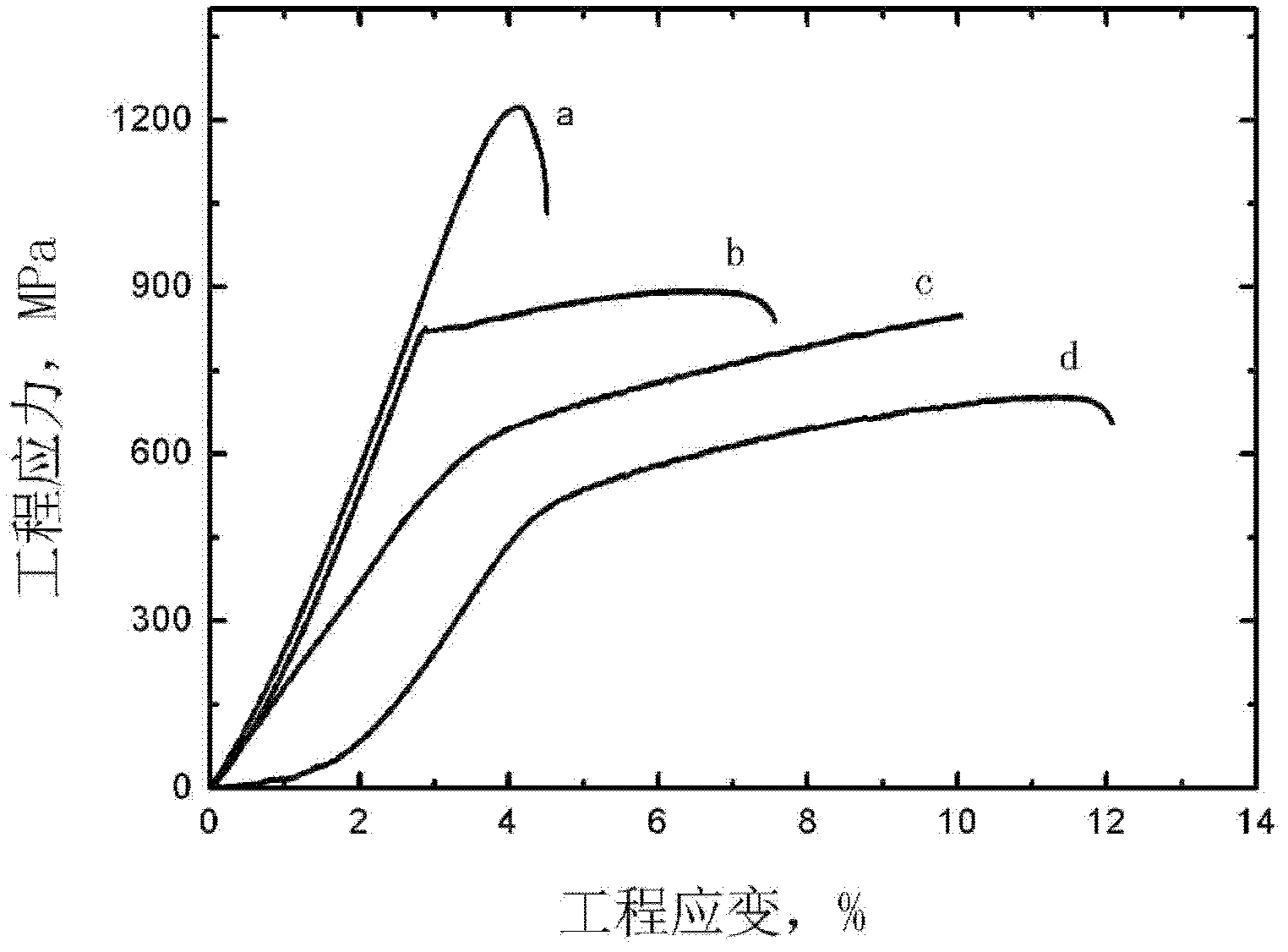

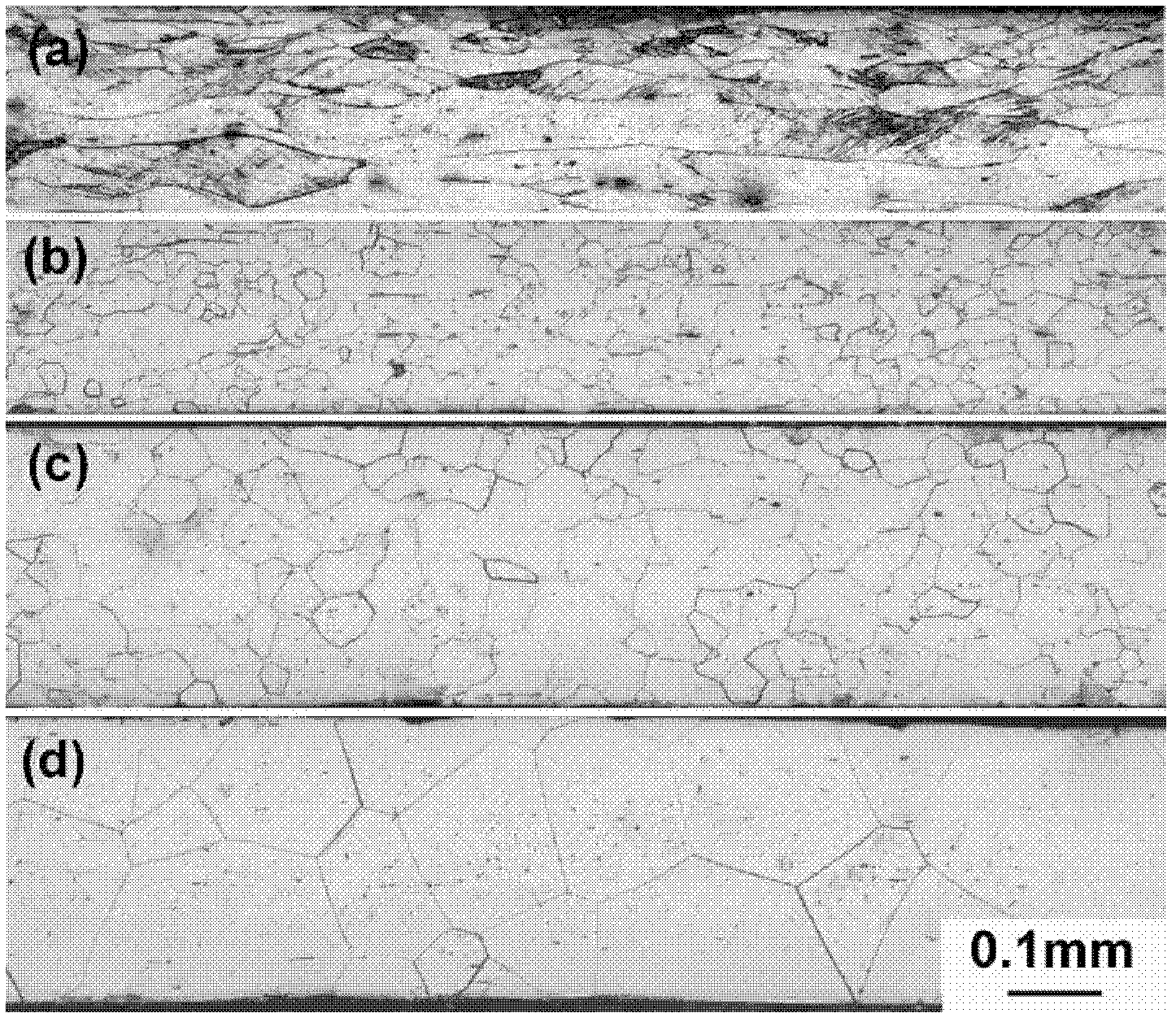

Embodiment 1

[0018] For high-silicon steel with a silicon content of 4% and no boron, the thickness of the plate is 2 mm after hot rolling, and electric pulse heat treatment is performed on it. The processing parameters are: electric pulse frequency 500Hz, pulse width 100μs, peak current density 80A mm -2 , the processing time is 30s, and the plate temperature rises to 850°C during the processing. After treatment, the yield strength and fracture strength of the treated sheet decreased to 550MPa and 650MPa under tensile conditions at 150°C.

Embodiment 2

[0020] For high-silicon steel with a silicon content of 5% and a boron content of 150ppm, the thickness of the plate is 1mm after warm rolling, and electric pulse heat treatment is performed on it. The processing parameters are: electric pulse frequency 350Hz, pulse width 80μs, peak current density 260A mm -2 , the processing time is 10s, and the plate temperature rises to 750°C during the processing. After the treatment, the yield strength of the plate under the tensile condition of 150°C decreased to 610MPa, and the breaking strength decreased to 750MPa.

Embodiment 3

[0022] For high-silicon steel with a silicon content of 6.5% and a boron content of 150ppm, the thickness of the plate is 1mm after warm rolling, and electric pulse heat treatment is performed on it. The processing parameters are: electric pulse frequency 194Hz, pulse width 70μs, peak current density 360A mm -2 , the processing time is 10s, and the plate temperature rises to 825°C during the processing. After the treatment, the yield strength of the sheet under tensile conditions at 150°C dropped to 675MPa, and the breaking strength dropped to 750MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com