Safe cooperation robot for assembly

A robot and safety technology, applied in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of high production and operation costs, the inability of operators to approach, and the inability to apply large-scale applications to achieve low manufacturing and operation costs, Improved working stability and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

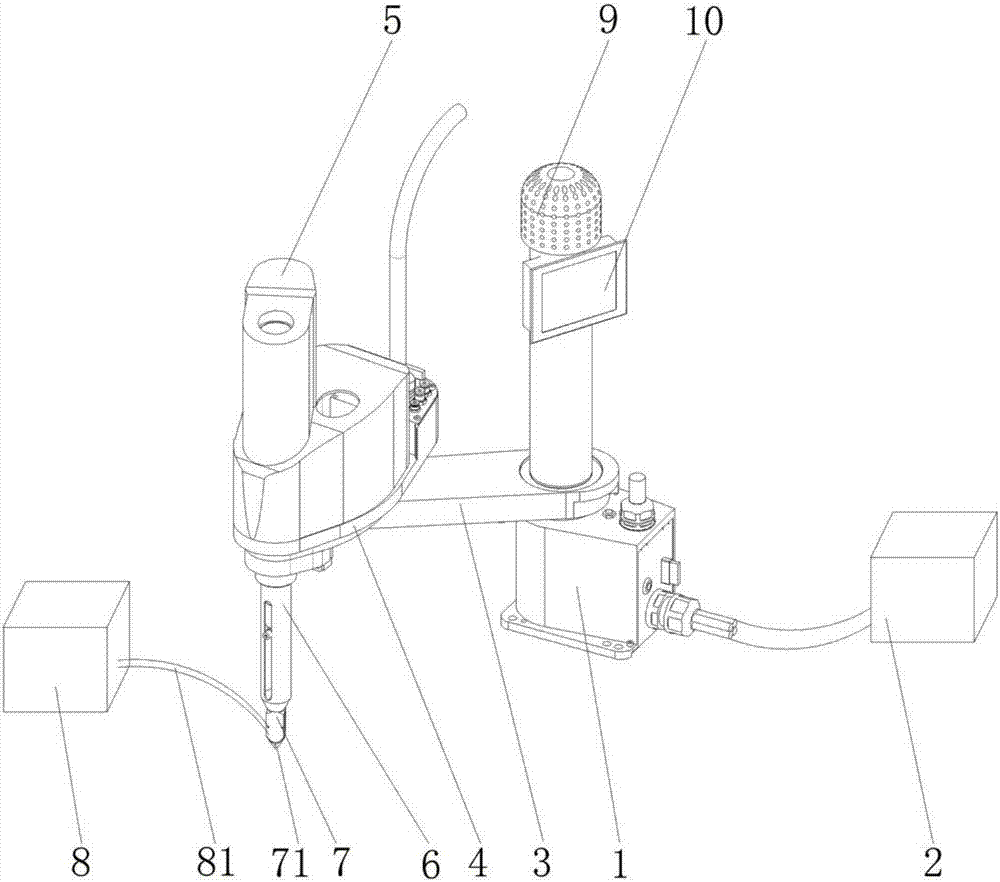

[0026] like figure 1 As shown, a safety collaborative robot for assembly in this embodiment includes: a base 1, a controller 2, a first articulated arm 3, a second articulated arm 4, an electric screwdriver 5, a connecting sleeve 6, a locking claw head 7, Vacuum nozzle 71 , feeder 8 , feeding pipeline 81 , sonar sensor 9 and touch screen 10 .

[0027] The connection relationship of the above components is as follows: the first articulated arm 3 is installed on the base 1, the second articulated arm 4 is installed on the first articulated arm 3, the first articulated arm 3 and the second articulated arm 4 Both are driven by an AC torque motor; the electric screwdriver 5 and the connecting sleeve 6 are both mounted on the second joint arm 4, and the screws provided in the connecting sleeve 6 are connected with the electric screwdriver 5 and the locking claw head 7 up and down respectively. , the screw is driven by the hollow shaft motor connected to it; the vacuum suction nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com