O-ring sleeving pack mechanism and operation method thereof

A technology of O-rings and sets, applied in the field of machinery, can solve problems such as low efficiency, increased labor costs, and unsuitability for mass production, etc., to achieve the effects of reducing axial movement, prolonging service life, and assisting smooth stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

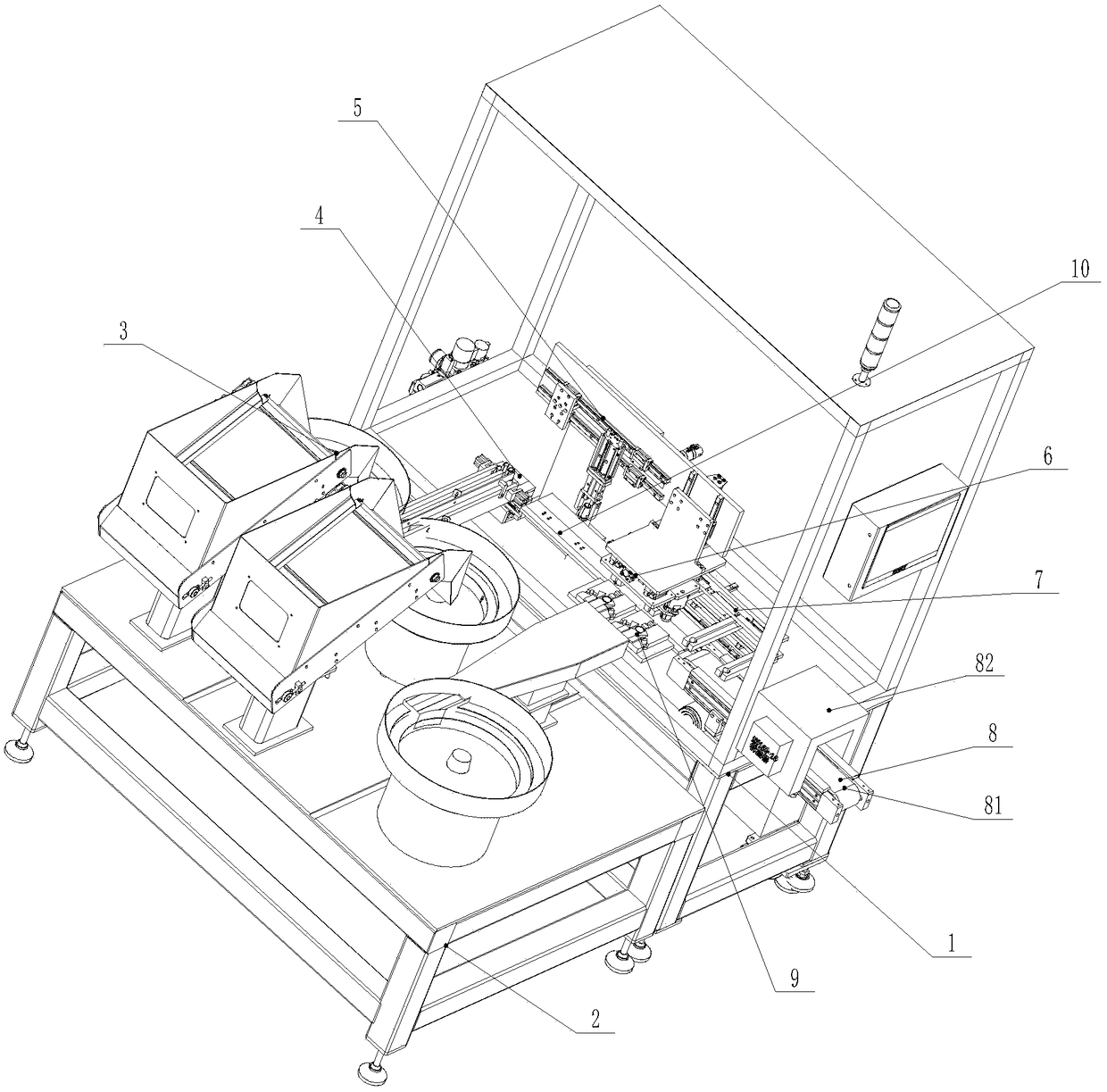

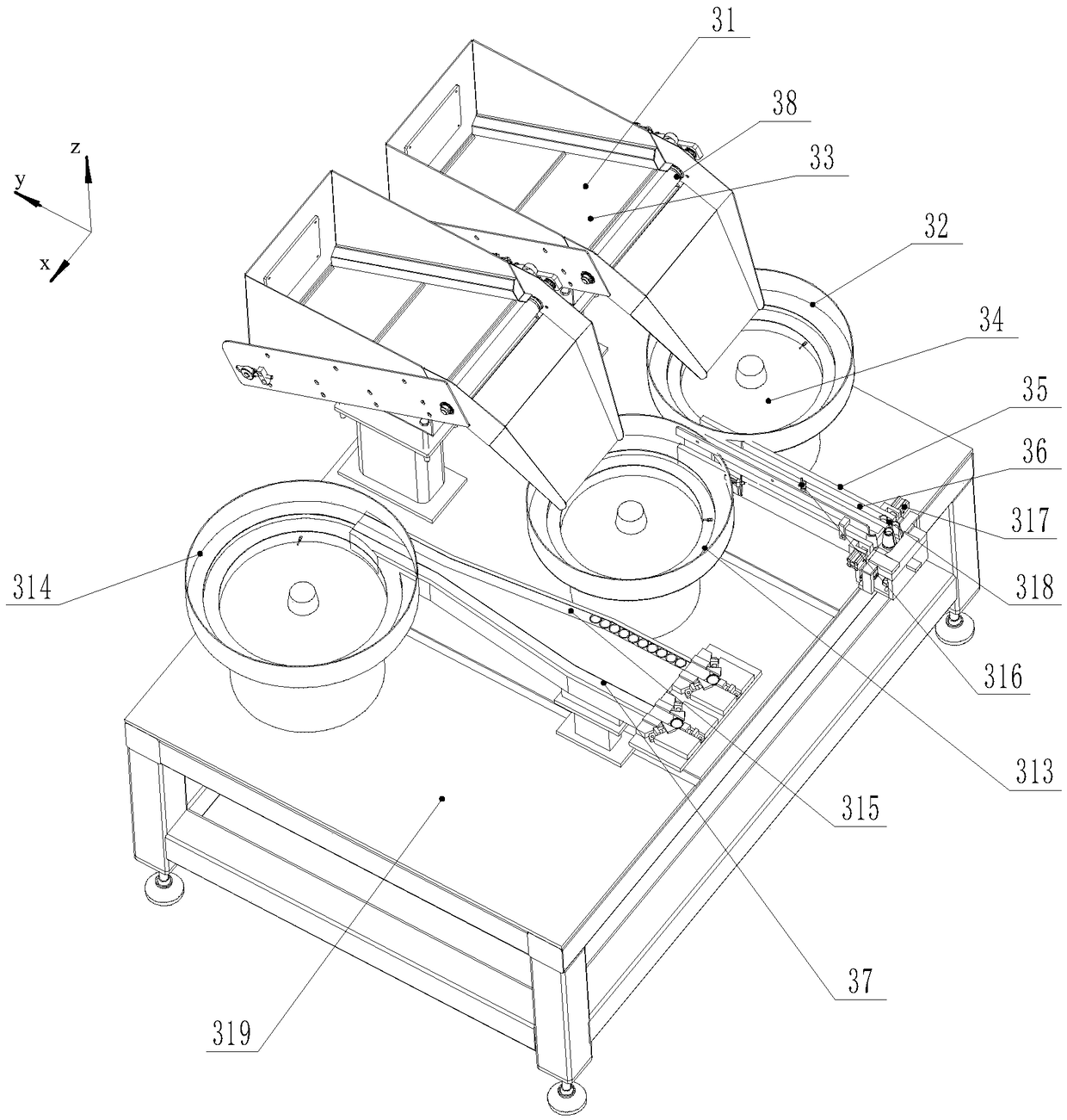

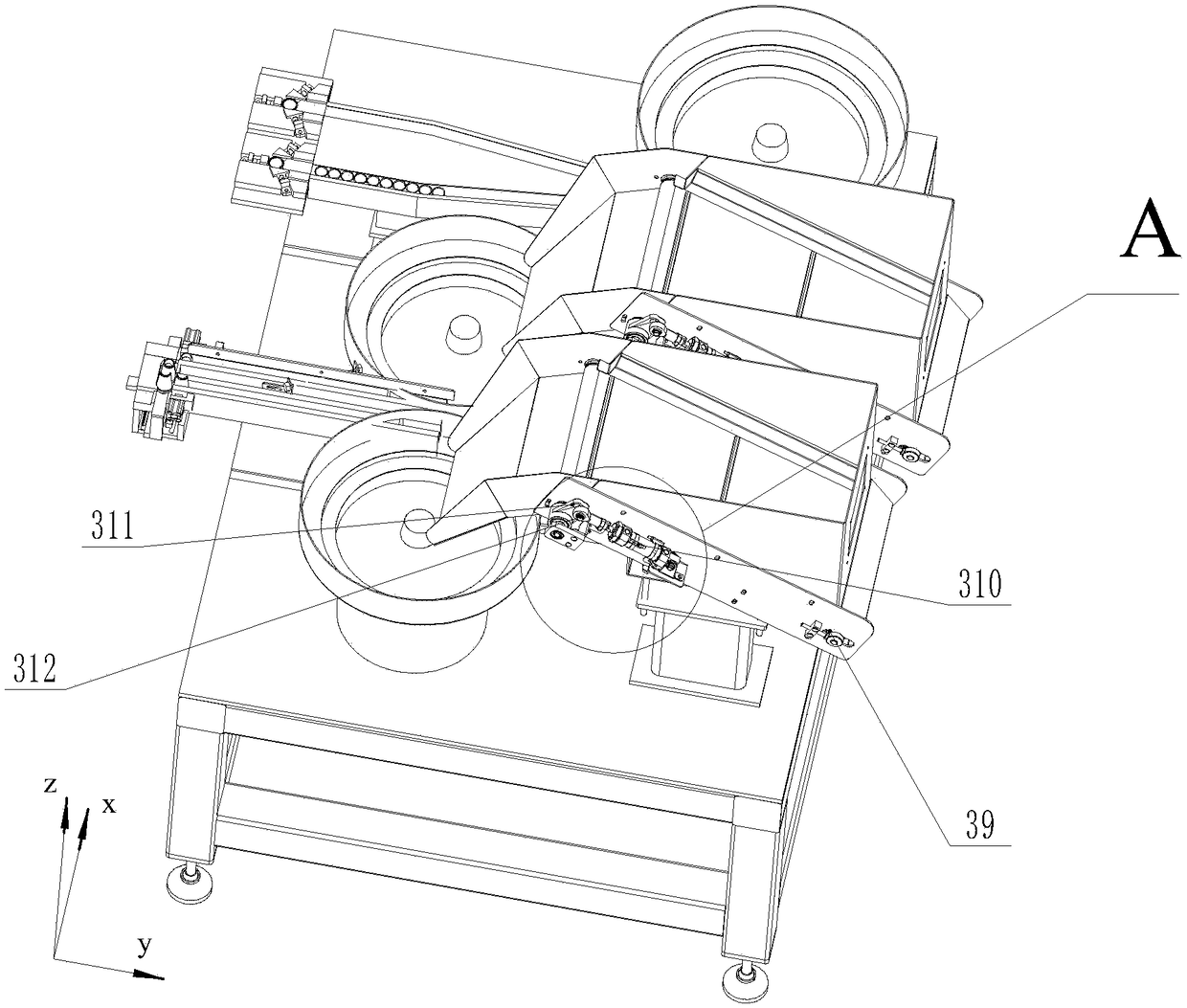

[0046] 1. Vibrating plate feeding device:

[0047] The anchor O-ring automatic assembly equipment of the present invention includes a vibrating disc feeding device 3, and the vibrating disc feeding device 3 includes a workbench 2 on which a conveying mechanism 31, a vibrating disc 32 and a direct vibrator 35 are fixedly arranged. , the discharge port of the conveying mechanism 31 corresponds to the hopper 34 of the vibrating plate 32, the direct vibrator 35 includes an anchorage direct vibrator 36 and an O-ring direct vibrator 37, the direct vibrator 35 and the outlet of the vibrating plate 32 The feed port is connected, the discharge port of the anchor straight vibrator 36 is connected with the anchor combining mechanism 4 , and the discharge port of the O-ring straight vibrator 37 is connected with the O-ring feeding platform 9 . The present invention adopts the conveyor belt 33 to transport the two halves of the anchors in the silo 1 and the silo 2 of the previous process t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com