Electrical machine for a wind energy installation

An electrical and magnetic technology, used in synchronous generators, synchronous machines, electrical components, etc., can solve problems such as weight increase, and achieve the effects of low total cost, reduced potential, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

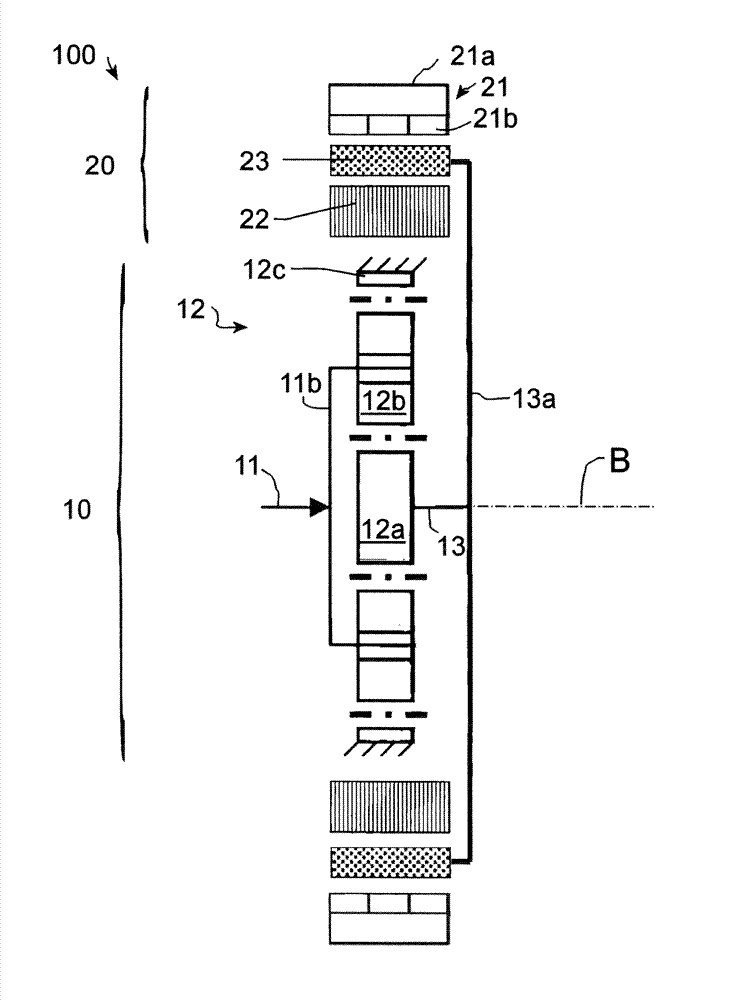

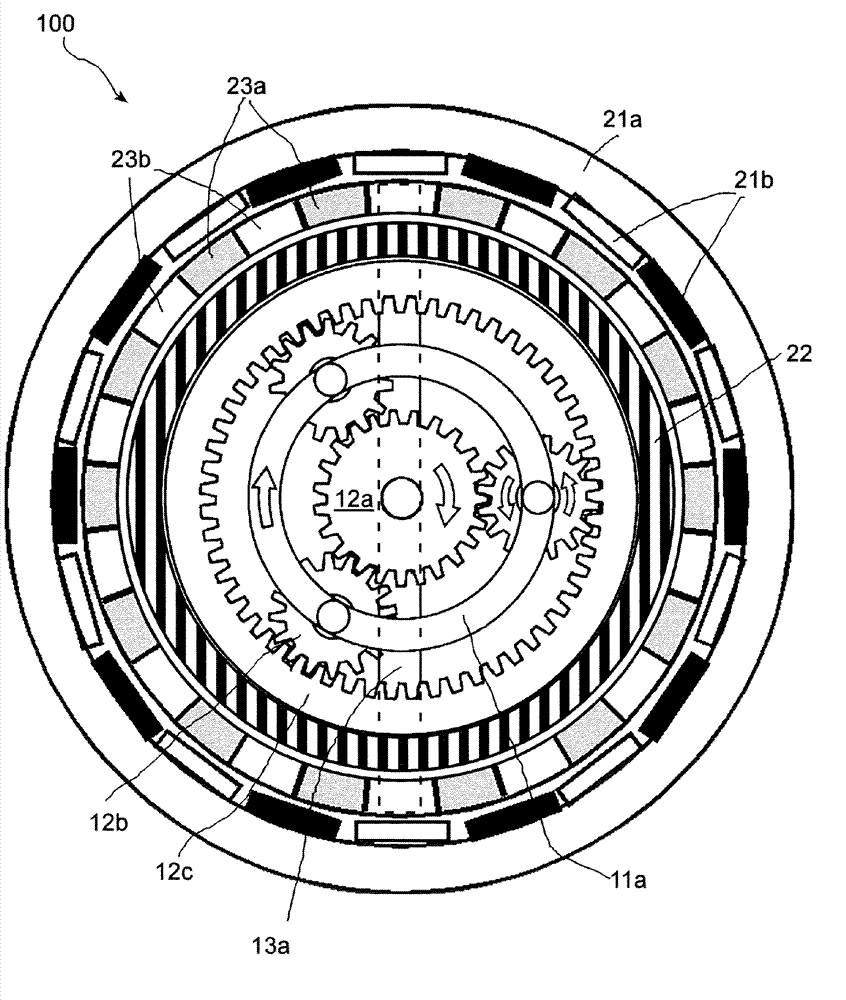

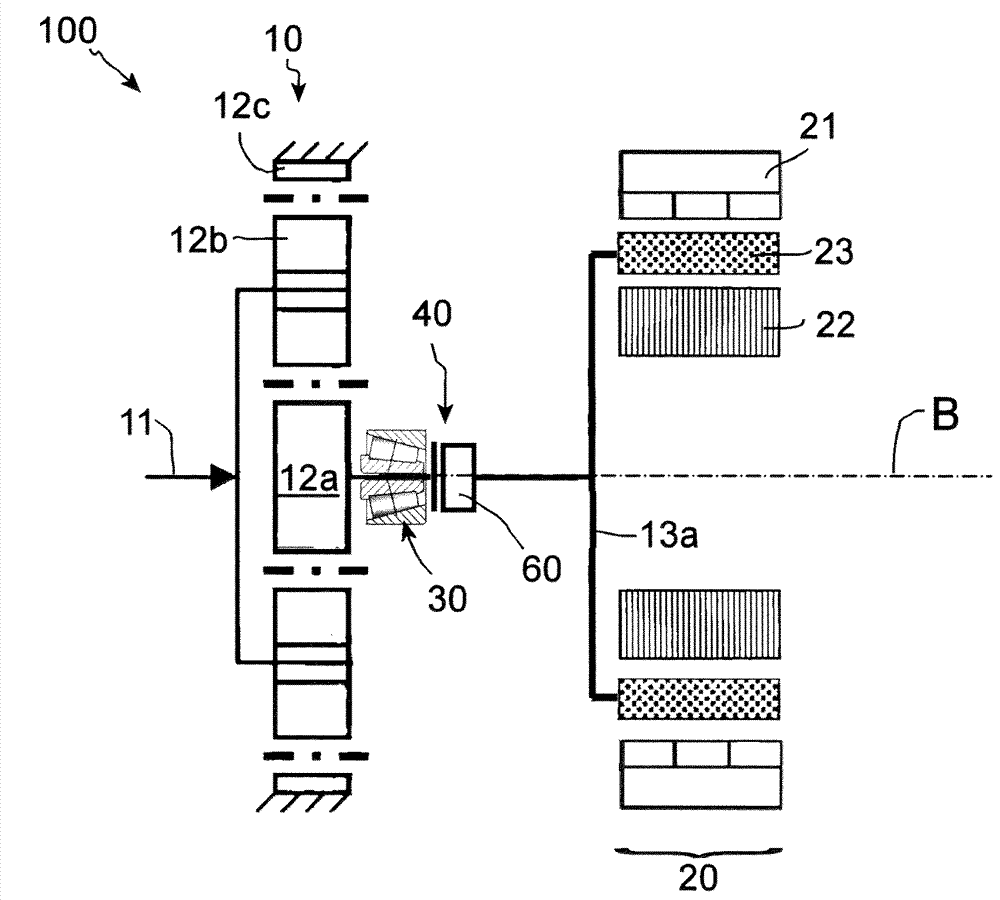

[0029] The electric machine 1 is indicated overall by 100 . In the embodiment shown, it has a planetary gear transmission arrangement 10 and an integrated (magnetic) transmission-generator unit 20 , which combines the function of a magnetic transmission with the generating function of the electric machine stand up.

[0030] The planetary transmission arrangement 10 includes a drive shaft 11 , which drives a planetary transmission stage 12 . The drive shaft 11 is connected via webs 11 b to the planetary gears 12 b of the planetary gear stage 12 . The internal gear 12c is arranged in a rotationally fixed manner, and the sun gear 12a drives the driven shaft 13 .

[0031] The working principle for power generation will now be explained below.

[0032] The electric machine has a fixed secondary part 21 and a fixed primary part 22 . In the exemplary embodiment shown, the secondary part is of separately excited construction, that is to say it is provided with a permanent magnet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com