Spiral-hemisphere branch combination type intelligent silicon nitride dry granulation integrated device

A silicon nitride dry and screw feeding device technology, applied in the direction of manufacturing tools, granulation in static tanks/troughs, ceramic molding machines, etc., can solve problems such as inability to change, single granulation effect, and small axial movement , to achieve the effect of improving the granulation effect, enhancing the granulation effect, and enhancing the axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

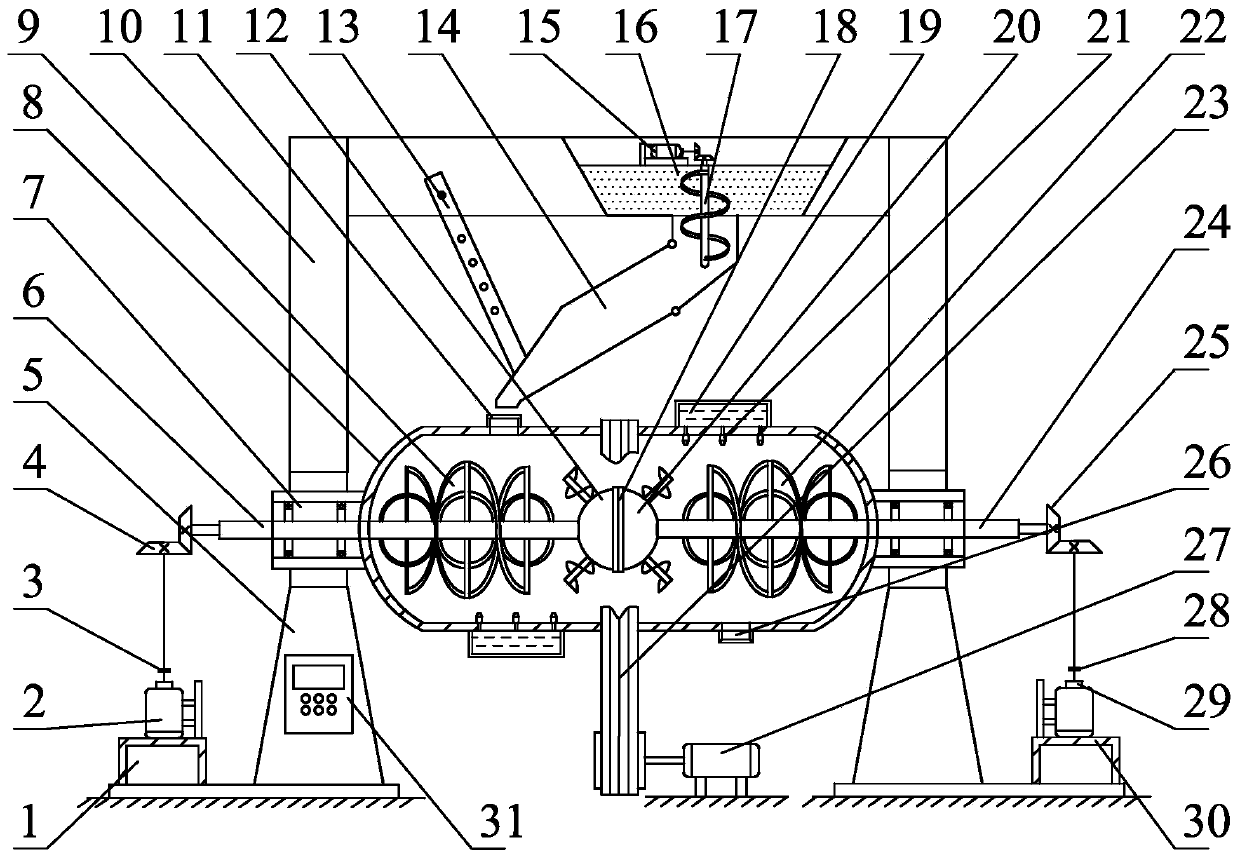

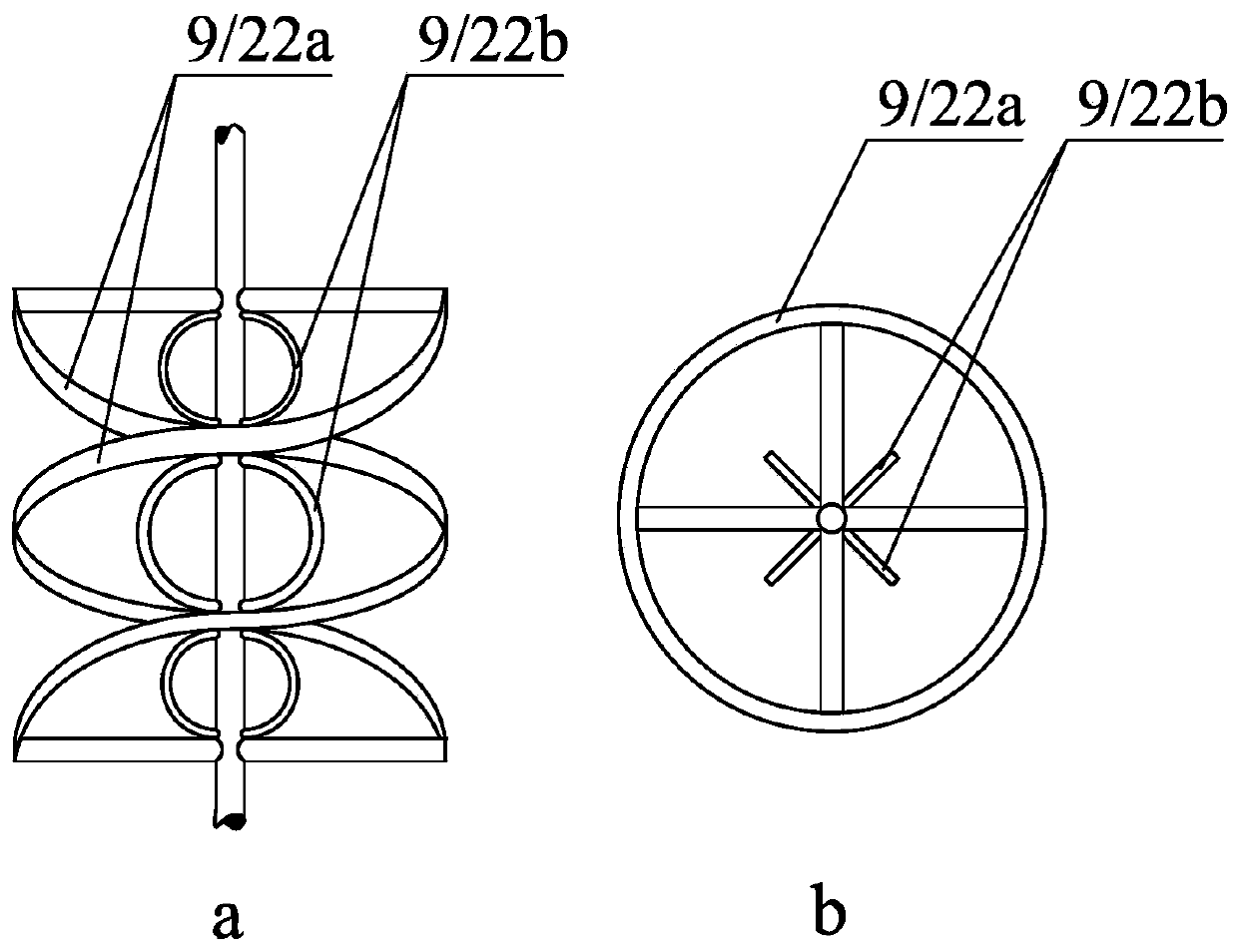

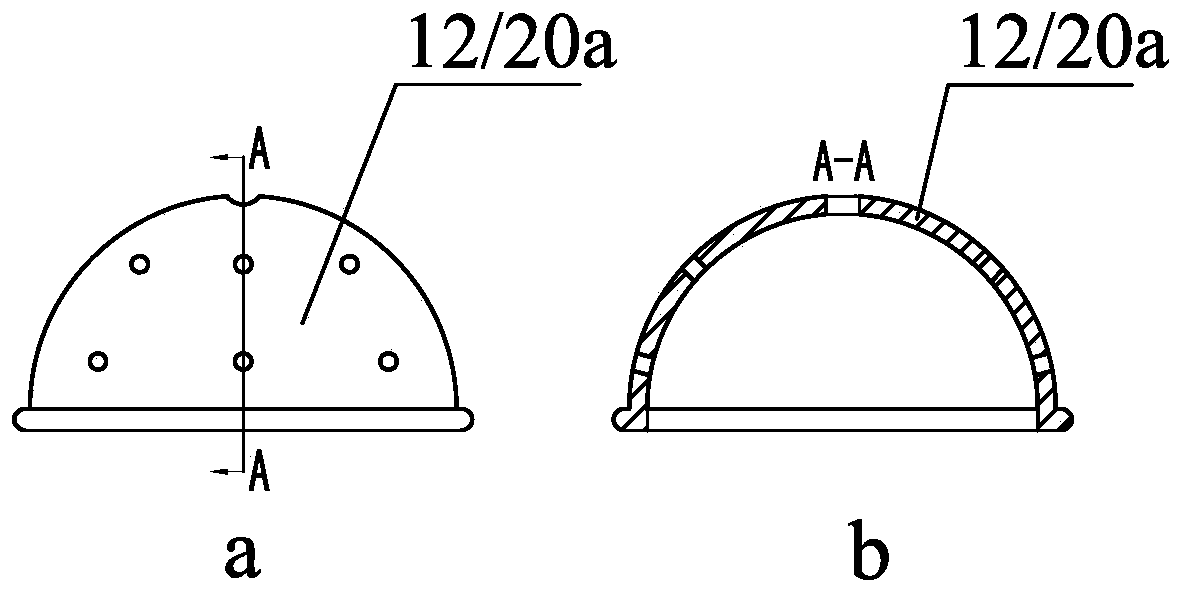

[0030] Figure 1 to Figure 6 Shown is a spiral-spherical branch combined intelligent silicon nitride dry granulation integrated device of the present invention, including a support system, a stirring granulation system, a feeding system, an atomization system, and an intelligent control system;

[0031] The supporting system includes the first drive motor fixing frame 1, the second driving motor fixing frame 30, the granulation chamber fixing frame 5, and the feeding bin fixing frame 10;

[0032] Such as figure 1 As shown, the stirring and granulating system includes a granulating chamber 8, a rotary structure 7, a belt 23, a driving motor 27 for the granulating chamber, and a stirring and granulating mechanism. The granulation chamber 8 is in the shape of a horizontal cylinder, and its two ends are arc-shaped and set on the granulation chamber fixed frame 5 through the rotary structure 7; Drive the granulation chamber 8 to rotate.

[0033] Such as figure 1As shown, the ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com