Two-edge special end milling cutter for through groove

A technology for end mills and through grooves, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc. It can solve the problems of edge chipping, uneven groove bottom, and difficult chip removal, etc., and achieves sharp end cutting edges, good surface quality, The effect of high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

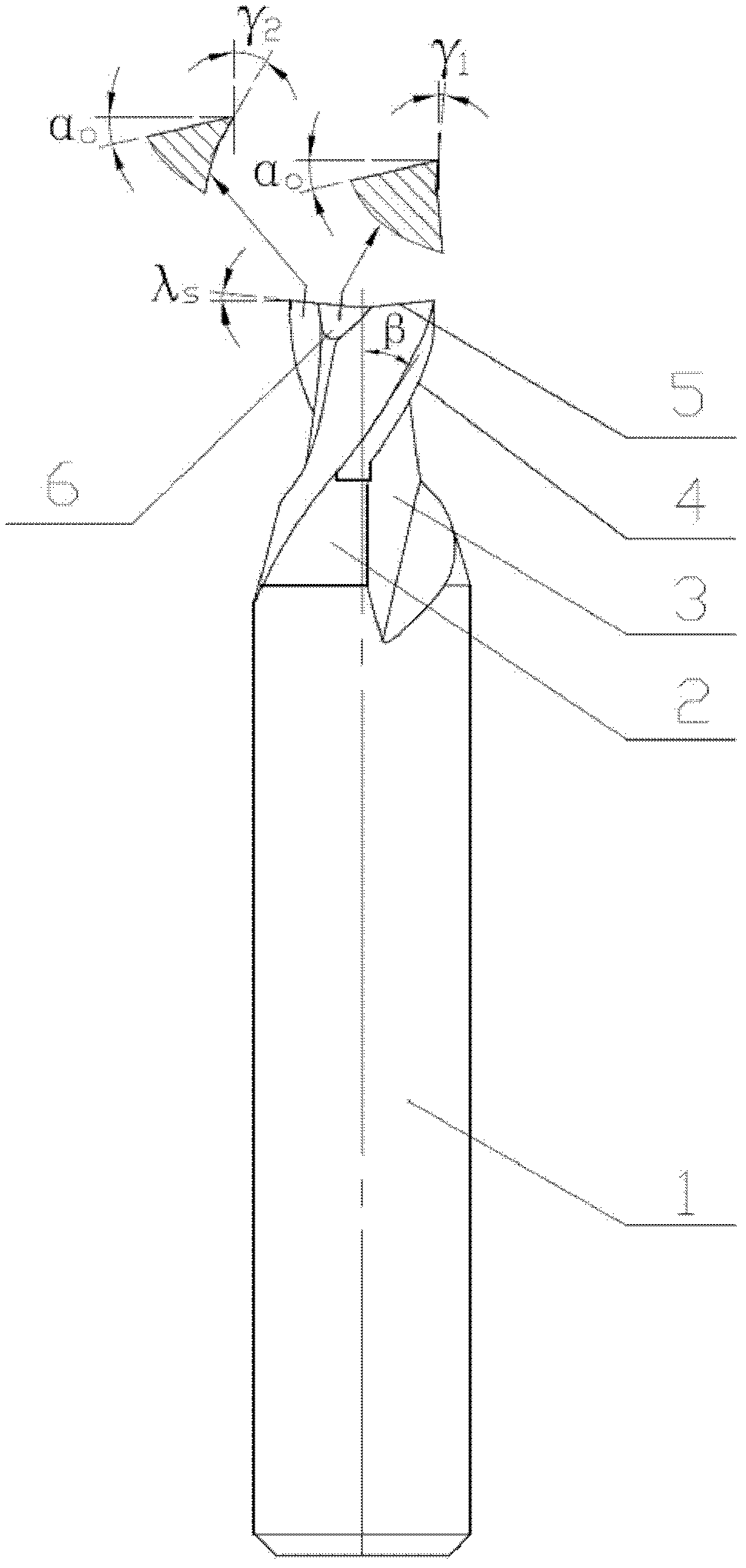

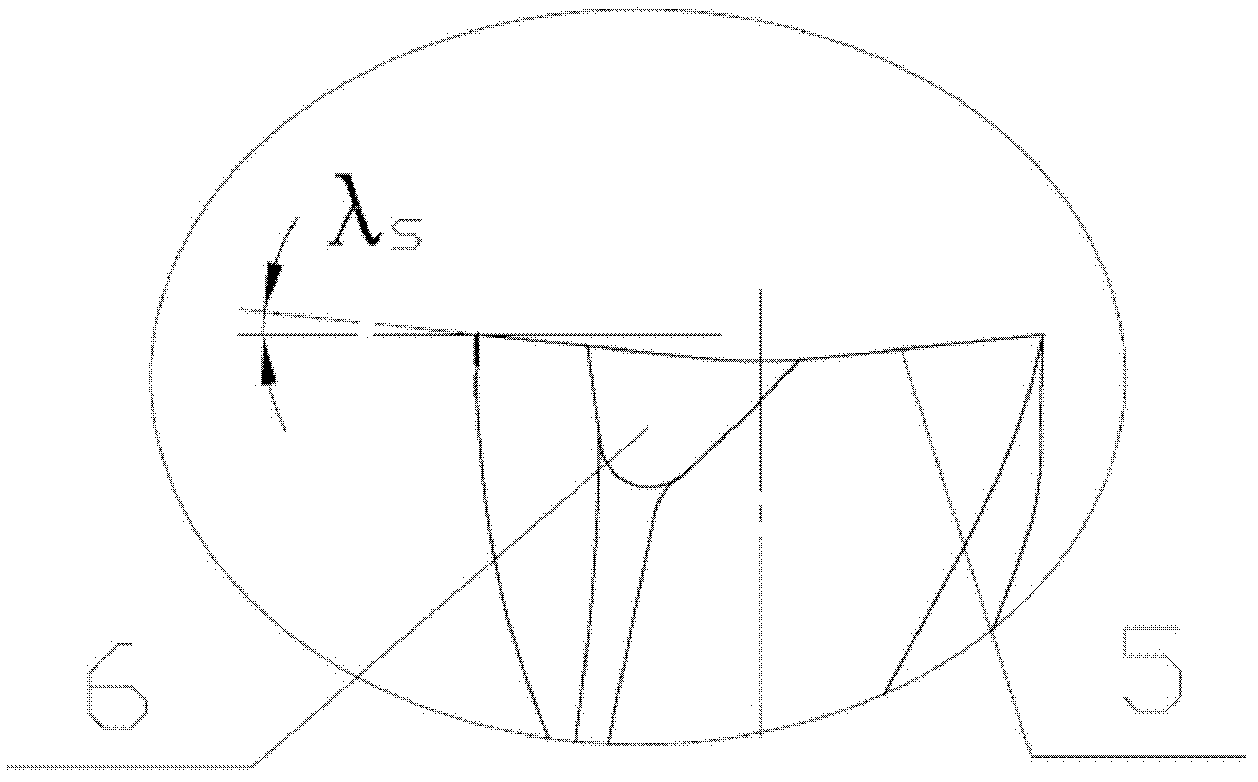

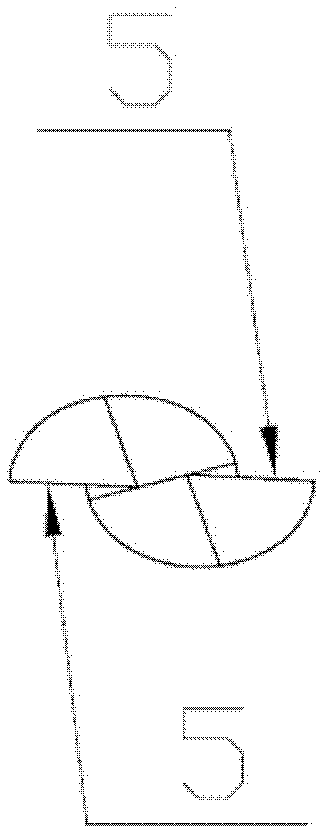

[0018] like Figure 1a , Figure 1b and Figure 1c As shown, the present embodiment is a two-edged through-groove special end mill, which processes the through-groove 7 on the workpiece 8 . The special end mill for two-edge through-groove includes a tool handle 1 and a cutter body 2. The cutter body 2 is composed of a spiral groove 3, a side edge 4, an end face cutting edge 5 and a chip removal groove 6. The end face cutting edge 5 is set on the cutter body 2. The top end, the inclination angle λ of the end face cutting edge 5 s = 3°; the chip removal groove 6 is set on the spiral groove 3 close to the center of the end face cutting edge 5, and the rake angle γ inside the end face cutting edge 5 1 = 0°, the rake angle γ on the outer side of the end face cutting edge 5 2 = 30°, clearance angle α of end face cutting edge 5 0 =12°, the helix angle β of the spiral groove 3=30°.

[0019] There are two end face cutting edges 5, which are arranged symmetrically on the top of the...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that the inclination angle λ of the end face cutting edge 5 s =8°; the rake angle γ of the inner side of the end face cutting edge 5 1 = 10°, the relief angle α of the end face cutting edge 5 0 = 15°.

[0024] The inclination angle of the end face cutting edge 5 is given by λ s = 3° change to λ s =8°; the cutting edge becomes sharper, and the processed groove bottom is flat, but the strength of the cutting edge is weakened. The rake angle on the inner side of the end face cutting edge 5 is determined by γ 1 = 0° changes to γ 1 =10°, the relief angle of the end face cutting edge 5 is determined by α 0 = 12° changed to α 0 =15°, making the cutting edge become sharper, but the strength is weakened.

Embodiment 3

[0026] The difference between this embodiment and Embodiment 1 is that the inclination angle λ of the end face cutting edge 5 s = 5°; the rake angle γ inside the end face cutting edge 5 1 = 5°, the relief angle α of the end face cutting edge 5 0 = 13°.

[0027] Compared with the end mills of Embodiment 1 and Embodiment 2, the end mills using this set of data have better cutting performance and service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com