Cutting blade and processing method thereof

A technology of cutting blades and processing methods, which is applied to the accessories of toolholders, metal processing equipment, turning equipment, etc., can solve the problems of difficult control of machining accuracy, high production cost of blades, and long cutting cycle, so as to reduce chipping Phenomenon, easy control of cutting direction, simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

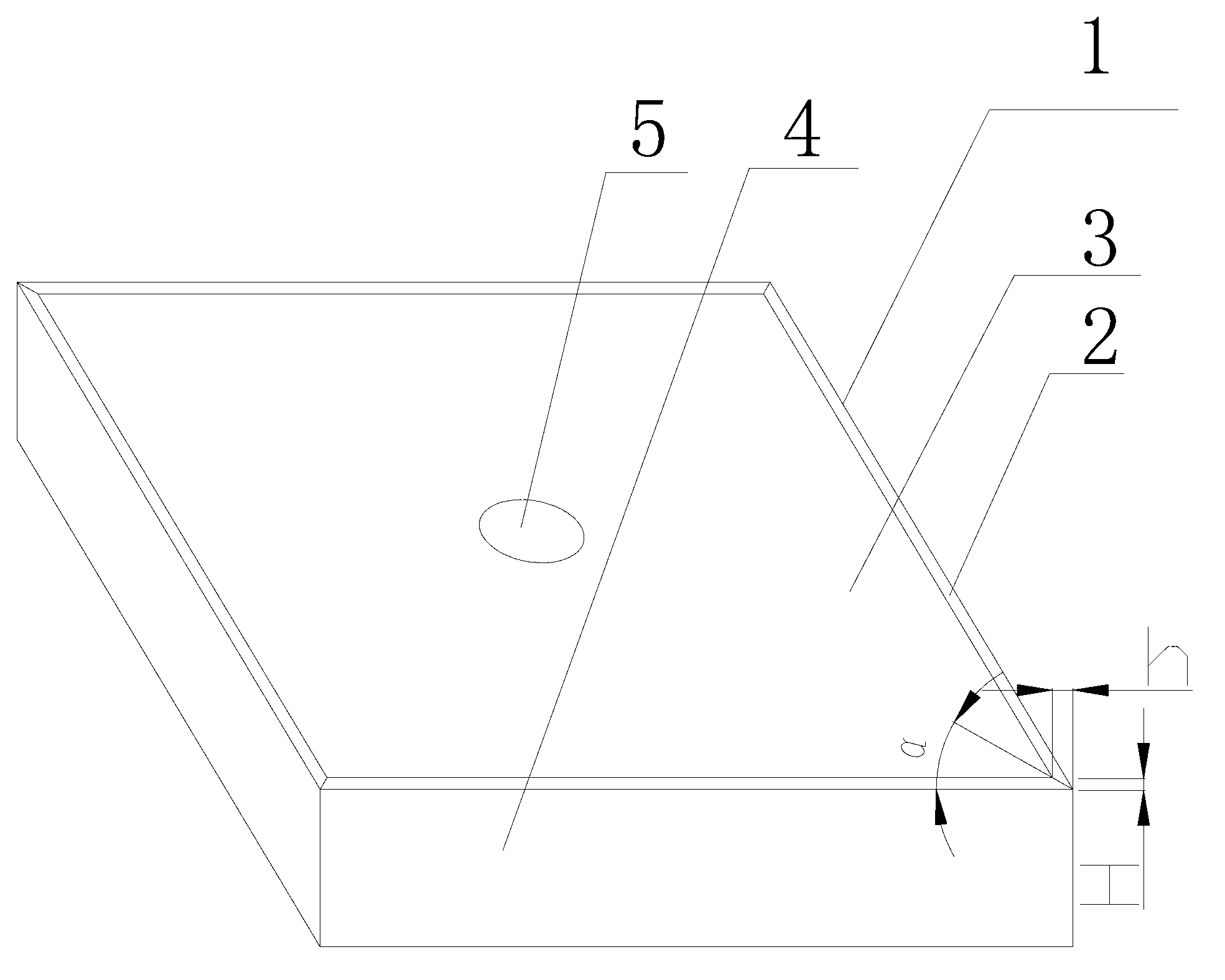

[0027] combine figure 1 , a cutting blade, comprising a blade body 1, the blade is provided with a blade portion, the blade portion is a chamfered edge structure, the chamfered edge structure forms an inclined plane 2, and the two ends of the inclined plane 2 are respectively connected to the rake face 3 and the rear face of the blade The knife face is 4, and the width of the chamfer is 0.15-1mm. Such as figure 1 , the width of the chamfer is H, h, that is, the vertical width and the horizontal width of the chamfer. The specific chamfer widths H and h are determined according to the size and application field of the blade.

[0028] The blade is a chamfered structure, so that the connection between the rake face and the flank face of the blade forms a transitional oblique plane. When cutting metal, the blade exerts a cutting external force on the workpiece, and the oblique plane of the chamfered structure contacts the workpiece. Compared with the rounded cutting edge in the ...

Embodiment 2

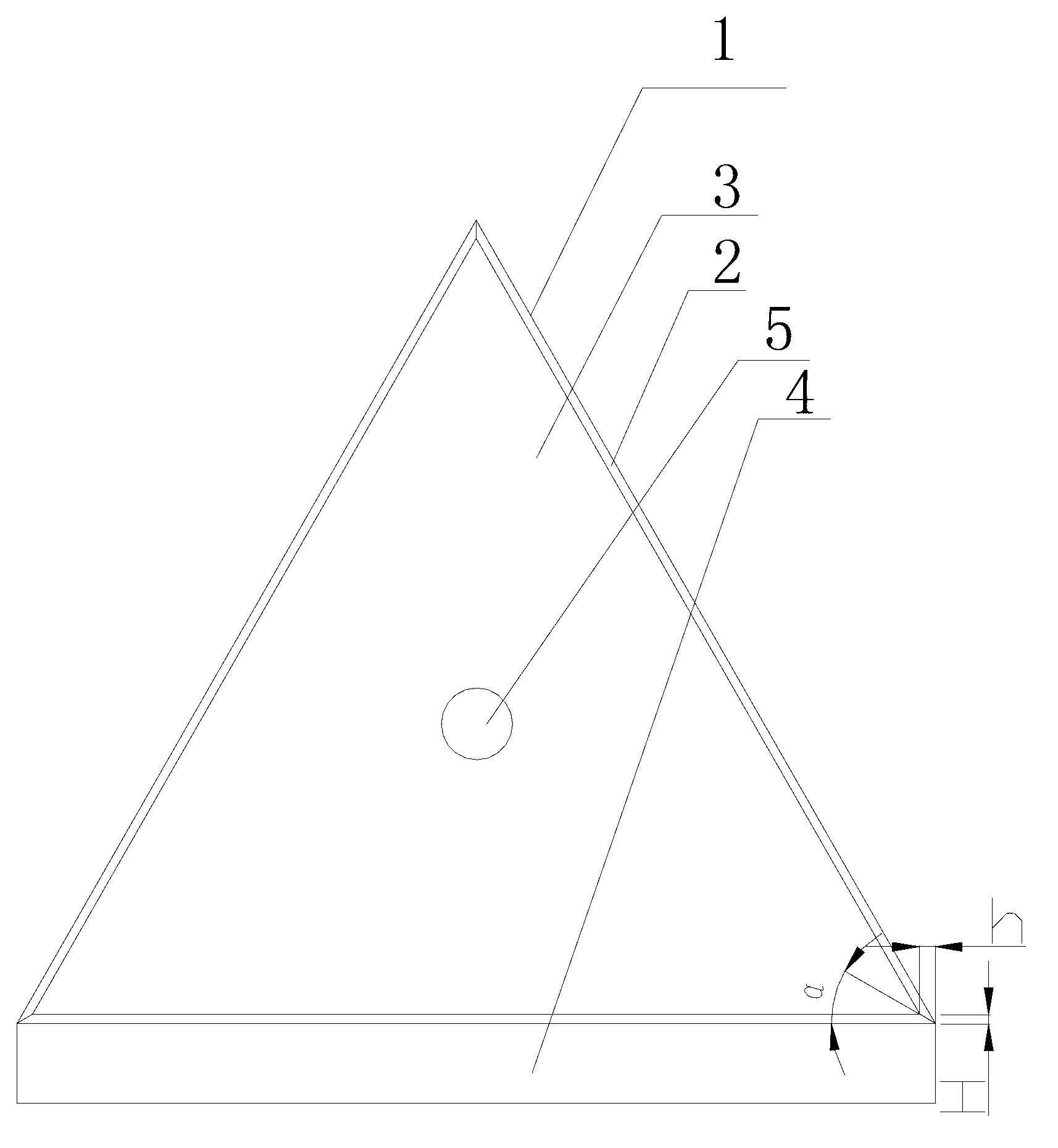

[0039] combine figure 2 , a cutting blade, comprising a blade body 1, the blade is provided with a blade portion, the blade portion is a chamfered edge structure, the chamfered edge structure forms an inclined plane 2, and the two ends of the inclined plane 2 are respectively connected to the rake face 3 and the rear face of the blade The knife face is 4, and the width of the chamfer is 0.15-1mm. Such as figure 2 , the width of the chamfer is H, h, that is, the vertical width and the horizontal width of the chamfer. The specific chamfer widths H and h are determined according to the size and application field of the insert.

[0040] The angle between the inclined plane and the horizontal plane is preferably 10-60 °, and the angle between the inclined plane and the horizontal plane is as follows figure 1In α, the inclination of the inclined plane is within this range, and the blade edge can easily apply cutting force to the workpiece. When the included angle between the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com